Composite film material for light-controlled release of nitric oxide, preparation method and application thereof

A light-controlled release, nitric oxide technology, applied in the field of biomedical engineering materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

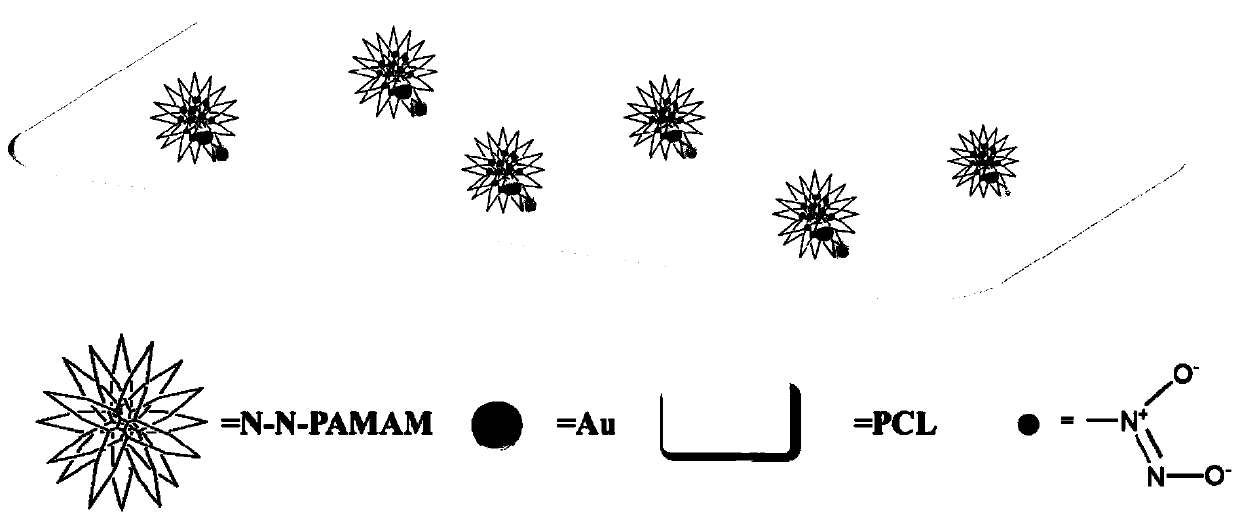

Method used

Image

Examples

Embodiment 1

[0086] (1) Synthesis of 3 generations of spherical dendritic polyamidoamines:

[0087] Dissolve ethylenediamine in methanol in an ice-water bath at 0°C, then drop it into the methanol solution of methyl acrylate, stir evenly, raise the temperature to 25°C and stir for 12 hours to obtain 0.5-generation ethylenediamine as the core PAMAM unit (N-N-P AMAM -D 0.5 ); N-N-PAMAM-D in an ice-water bath 0.5 Dissolve in methanol, drop into the methanol solution of ethylenediamine, stir evenly, raise the temperature to 25°C and stir for 12 hours to obtain the N-N-PAM AM motif (N-N-PAMAM-D 1 ); wherein, the molar ratio of ethylenediamine to methyl acrylate is 1:4; the N-N-PAMAM-D 0.5The molar ratio with ethylenediamine is 1:4; the consumption of described methyl alcohol is based on the methyl acrylate of every 10ml of methanol dissolved in 1ml; the consumption of described methyl alcohol is calculated in the ethylenediamine of every 10ml of methanol dissolved in 1ml; -PAMAM-D 0.5 The d...

Embodiment 2

[0091] (1) Synthesis of 3 generations of spherical dendritic polyamidoamines:

[0092] Dissolve ethylenediamine in methanol in an ice-water bath at 0°C, then drop it into the methanol solution of methyl acrylate, stir evenly, raise the temperature to 35°C and stir for 48 hours to obtain 0.5-generation ethylenediamine as the core PAMAM unit (N-N-PAMAM -D 0.5 ); N-N-PAMAM-D in an ice-water bath 0.5 Dissolve in methanol, drop into the methanol solution of ethylenediamine, stir evenly, raise the temperature to 35°C and stir for 48 hours to obtain the N-N-PAMAM unit (N-N-PAMAM-D 1 ); wherein, the molar ratio of ethylenediamine to methyl acrylate is 1:8; the N-N-PAMAM-D 0.5 The mol ratio with ethylenediamine is 1:12; The consumption of described methyl alcohol is based on the methyl acrylate of every 10ml methanol dissolution 5ml; The consumption of described methyl alcohol is the ethylenediamine of every 10ml methanol dissolution 5ml; The N-N- PAMAM-D 0.5 The dosage is 5g N-N-P...

Embodiment 3

[0096] (1) Synthesis of 3 generations of spherical dendritic polyamidoamines:

[0097] Dissolve ethylenediamine in methanol in an ice-water bath at 0°C, then drop it into the methanol solution of methyl acrylate, stir evenly, raise the temperature to 30°C and stir for 24 hours to obtain 0.5-generation ethylenediamine as the core PAMAM unit (N-N-PA MAM-D 0.5 ); N-N-PAMAM-D in an ice-water bath 0.5 Dissolve in methanol, drop into the methanol solution of ethylenediamine, stir evenly, raise the temperature to 35°C and stir for 24 hours to obtain the N-N-PAMA M motif (N-N-PAMAM-D 1 ); wherein, the molar ratio of ethylenediamine to methyl acrylate is 1:6; the N-N-PAMAM-D 0.5 The molar ratio with ethylenediamine is 1:8; The consumption of described methanol is based on the methyl acrylate of 3ml per 10ml of methanol; -PAMAM-D 0.5 The dosage is 2.5g N-N-PAMAM-D per milliliter of methanol 0.5 count.

[0098] (2) Synthesis of dendritic polyamide N-N-PAMAM with 3-generation ethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com