Bonding tooling for a bread machine

A bread machine and tooling technology, applied in the field of bonding tooling of bread machines, can solve the problems of inaccurate positioning of the display screen and the bracket, easy deviation of the bonding position, unfavorable cleaning, etc. , avoid adjustment, avoid the effect of glue overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

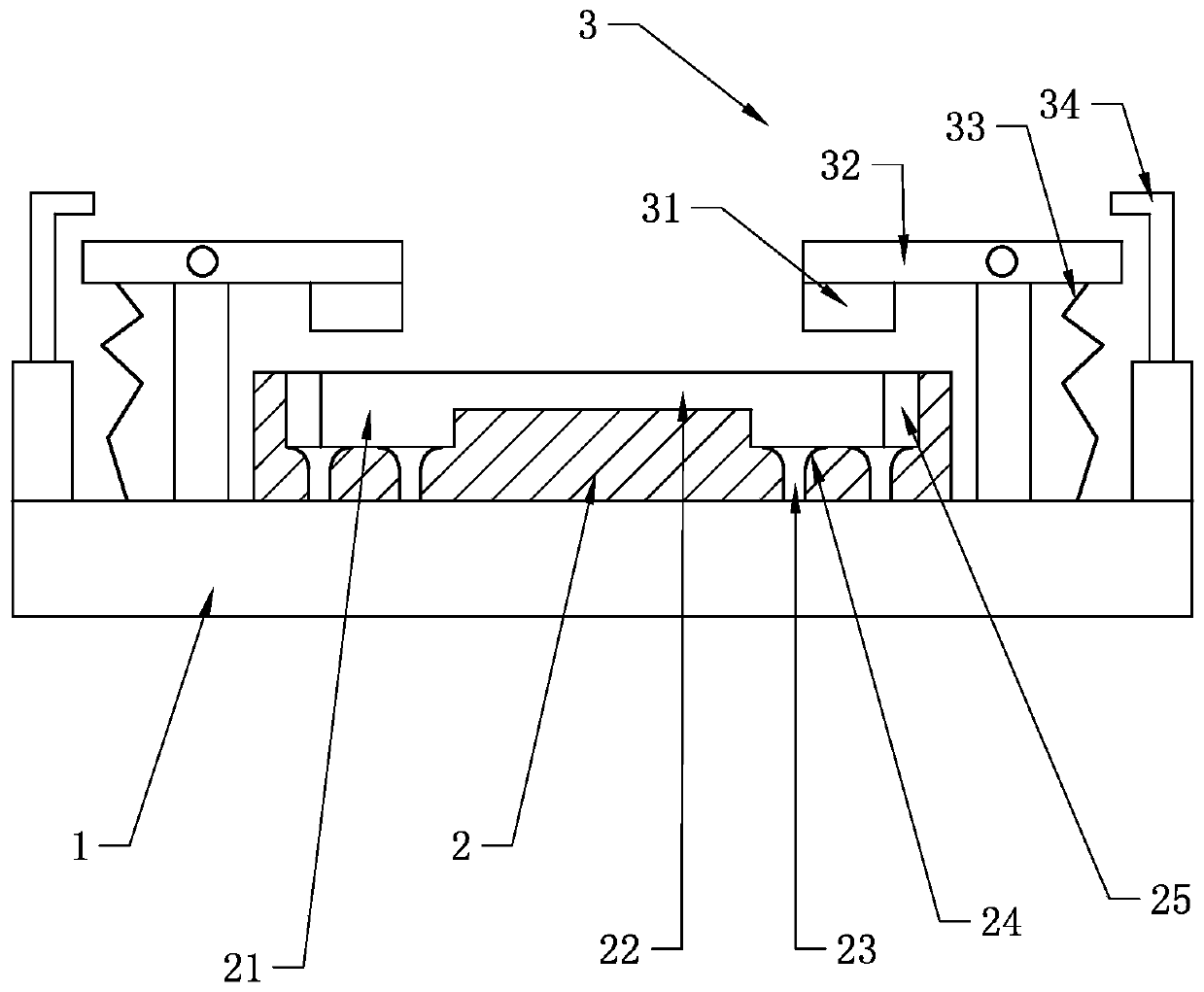

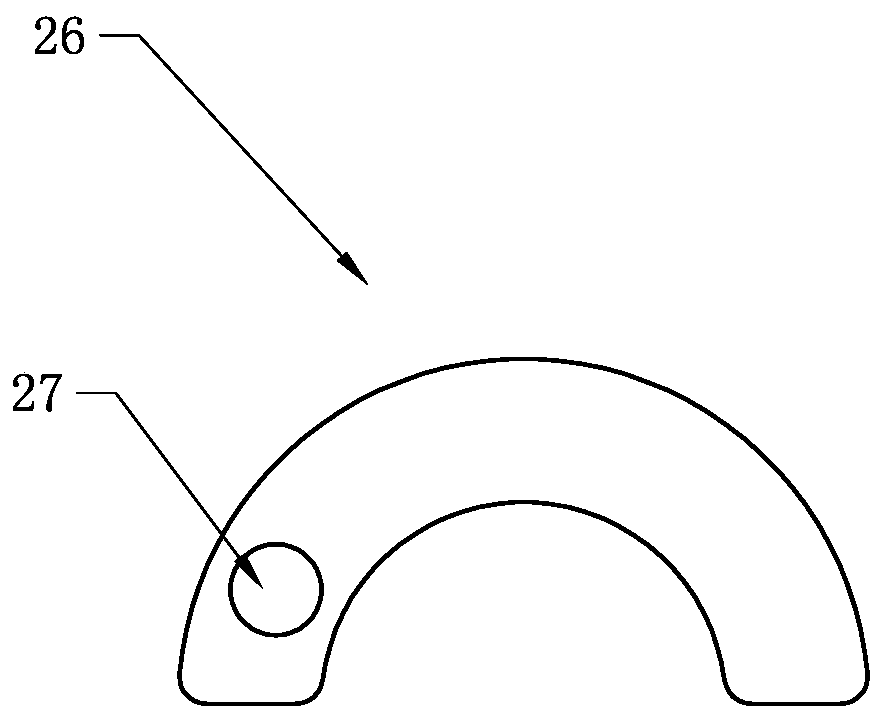

[0016] Such as figure 1 As shown, a bonding tool for a bread machine includes a base 1, the base 1 is provided with a first positioning plate 2 and a plurality of pressing components 3, and the plurality of pressing components 3 are arranged on one side of the first positioning plate 2, and the first positioning plate 2 The top is provided with a first groove 21 for accommodating the bracket. The depth of the first groove 21 is greater than the thickness of the bracket. The side wall of the first groove 21 is provided with a first gap 25, and the first gap 25 is arranged in the first groove. 21 at the junction of two adjacent side walls.

[0017] The position of the pressing assembly 3 can be adjusted according to the structure of the bracket.

[0018] In this embodiment, by setting the first positioning plate 2, the top of the first positioning plate 2 is provided with a first groove 21 for accommodating the bracket, which is convenient for gluing the bracket, and the gluing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com