Robot joint tail end residual vibration restraining method based on input shaper

A robot joint and input shaping technology, applied in manipulators, manufacturing tools, etc., can solve problems affecting the vibration suppression effect of the input shaper, system output time lag, etc., to reduce system time lag, enhance robustness, and reduce sensitivity degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

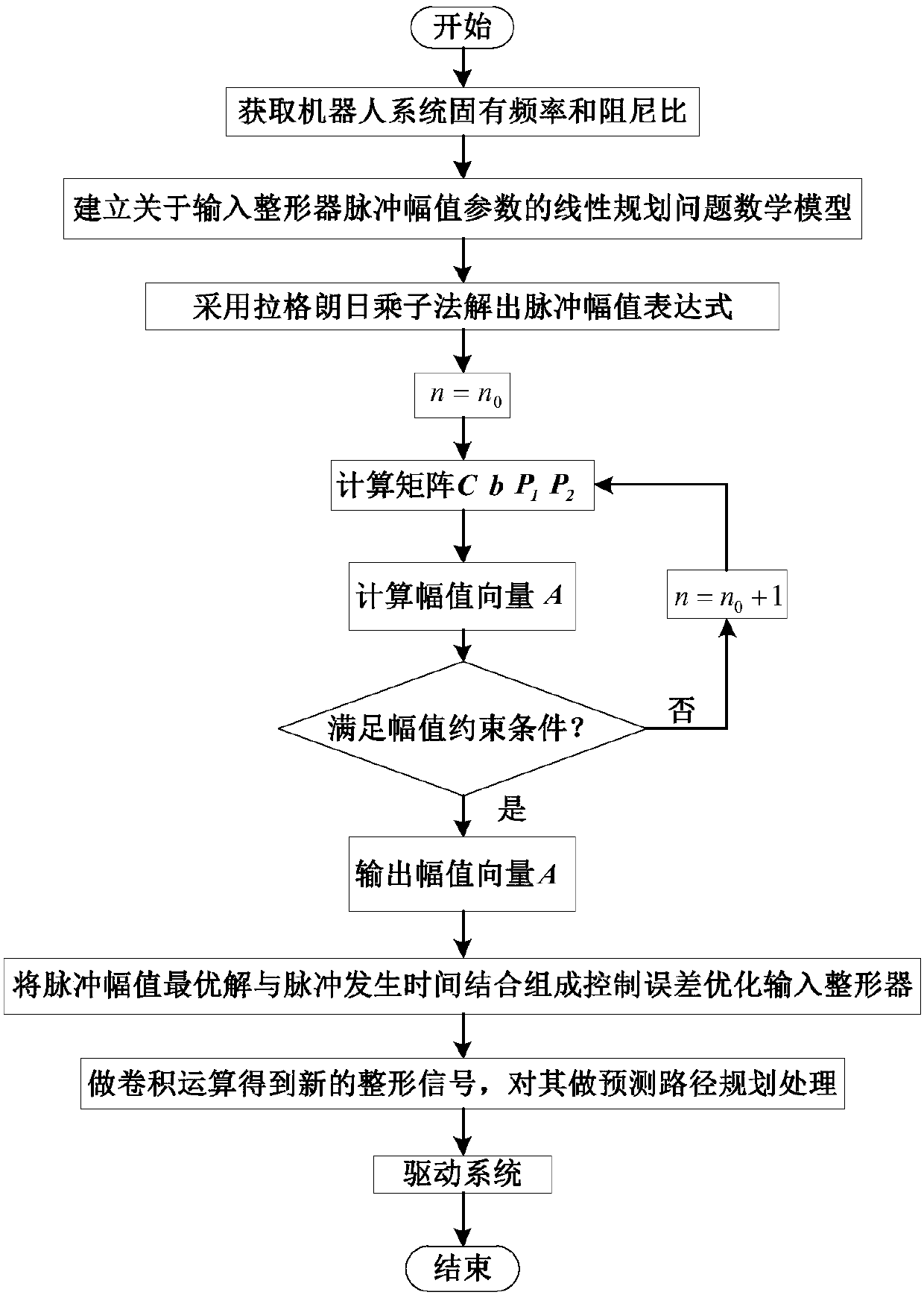

[0062] Such as figure 1 As shown, a method for suppressing residual vibration at the end of a robot joint based on an input shaper includes the following steps:

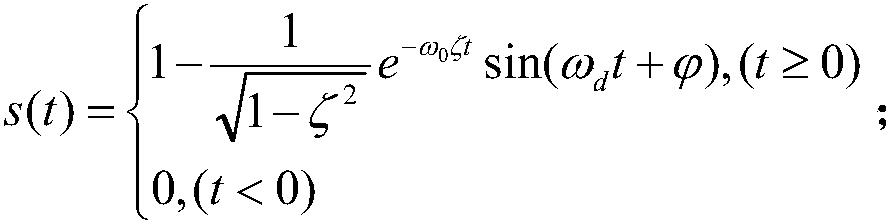

[0063] Step 1: Obtain the undamped natural frequency ω of the robot system 0 and damping ratio ζ;

[0064] Step 2: establishing a linear programming problem mathematical model about the input shaper pulse amplitude parameter;

[0065] Step 3: use the Lagrange multiplier method to solve the pulse amplitude expression, and iteratively obtain the optimal solution of the pulse amplitude;

[0066] Step 4: Combining the optimal solution of the pulse amplitude with the pulse generation time to form a control error optimization input shaper;

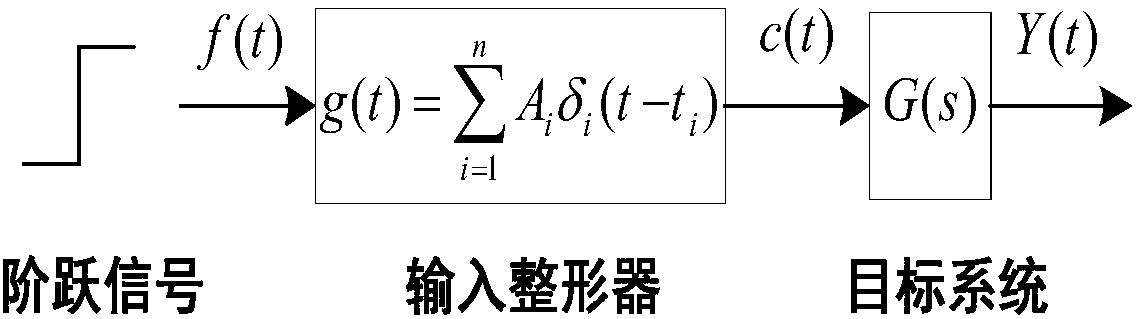

[0067] Step 5: Input the reference signal and control error optimization into the shaper to perform convolution operation to obtain a new shaping signal, and then use the signal to drive the system to suppress the residual vibration at the end of the robot (see figure 2 ).

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com