Beet vine cutting machine

A beet and rack technology, applied in the field of beet seedling killing machines, can solve the problems of inability to effectively distinguish the size of beets, inability to achieve effective profiling, and decline in the utilization rate of beets, so as to achieve high cutting efficiency, reduce farmers' workload, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

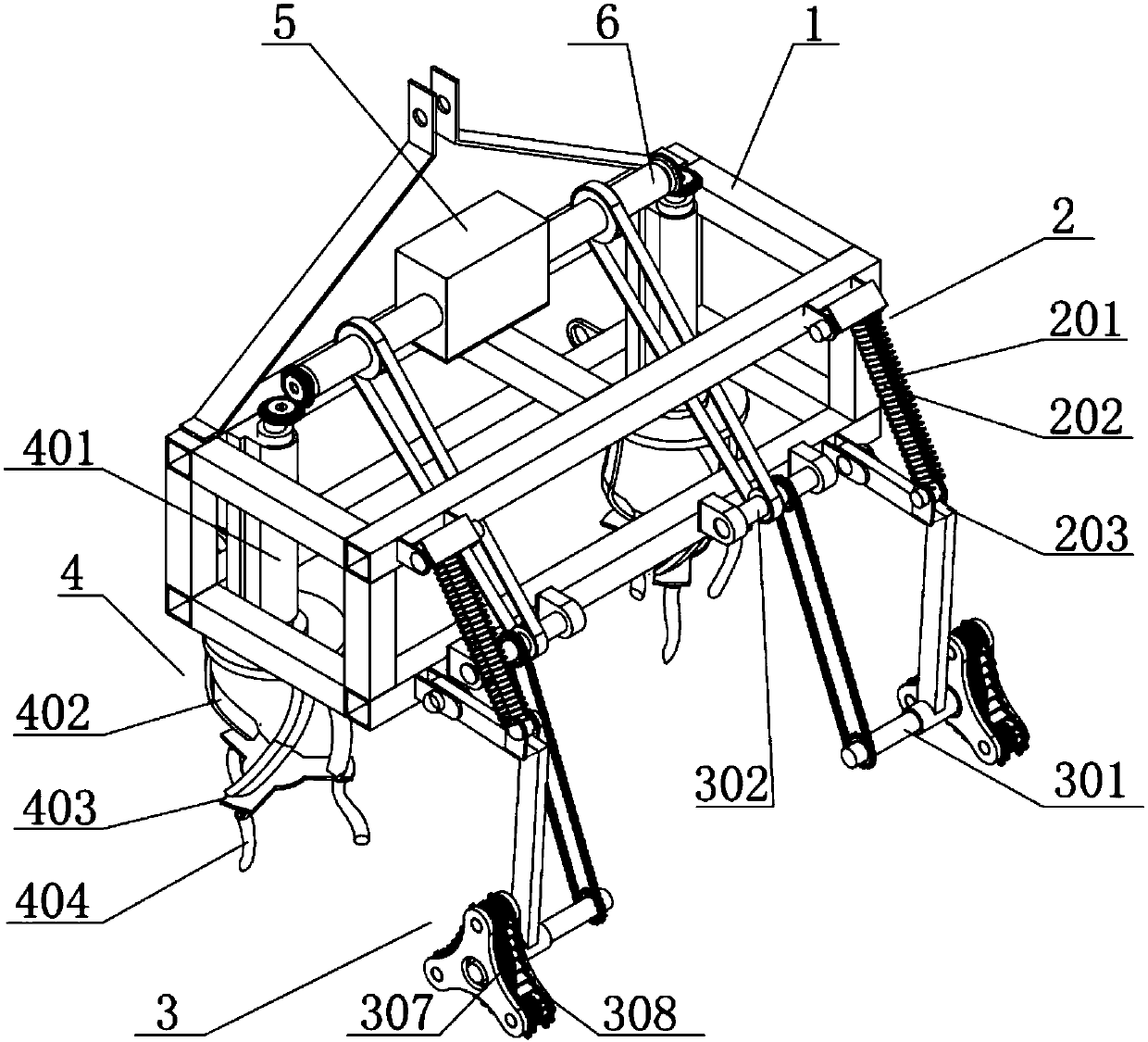

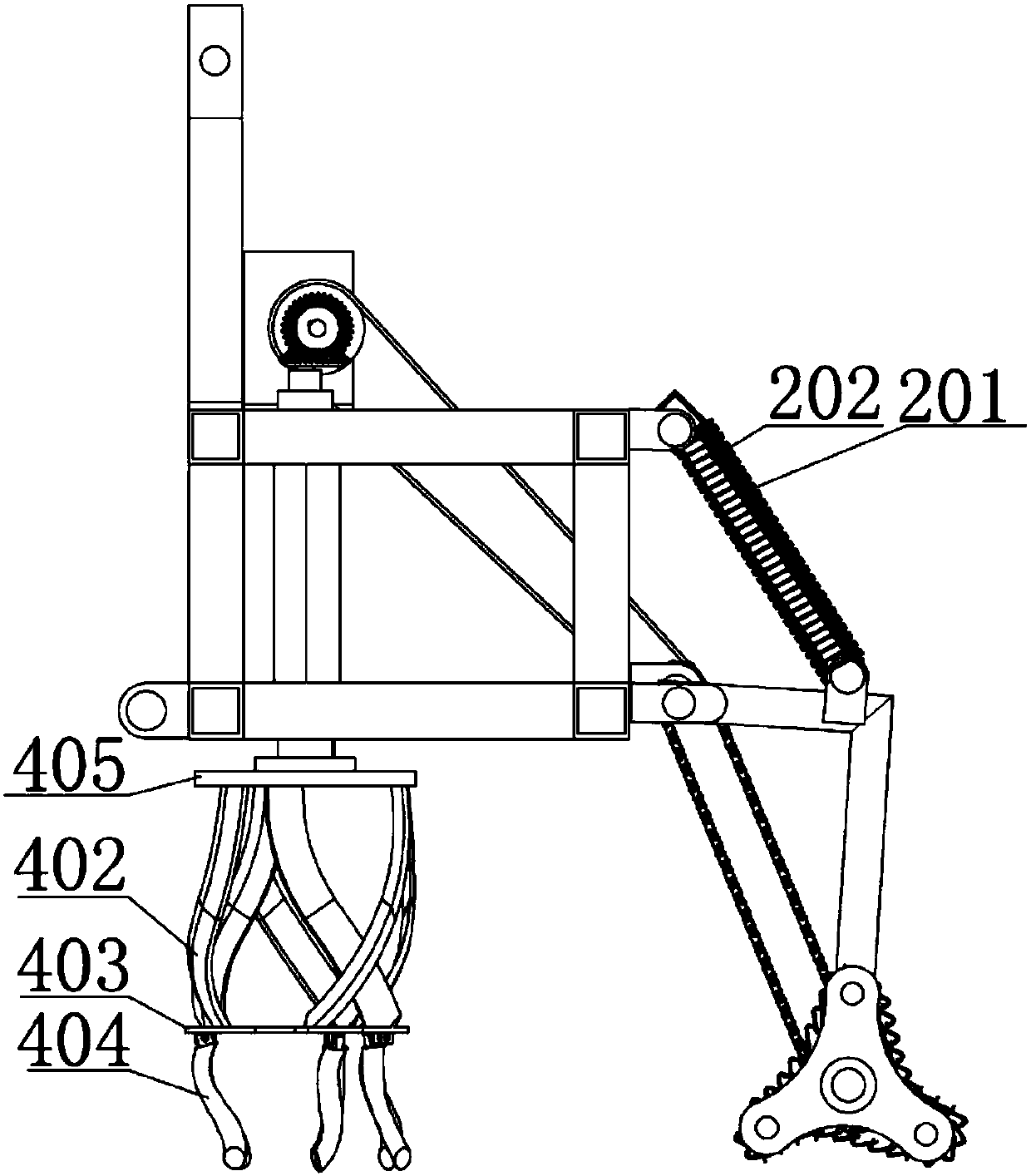

[0023] Such as figure 1 As shown, the sugar beet seedling killing machine of the present invention comprises frame 1, main drive shaft 6, damping device 2, top cutting device 3 and rotary leaf removal device 4, main drive shaft 6, shock absorbing device 2, top cutting The device 3 and the rotary leaf removal device 4 are all arranged on the frame 1, wherein the rotary leaf removal device 4 is arranged under the front part of the frame 1, and the shock absorbing device 2 and the top cutting device 3 are located at the rear of the frame 1. The shock device 2 is located above the top cutting device 3, and the shock absorbing device 2 is connected with the top cutting device 3. The main transmission shaft 6 is respectively connected to the top cutting device 3 and the rotary defoliating device 4 .

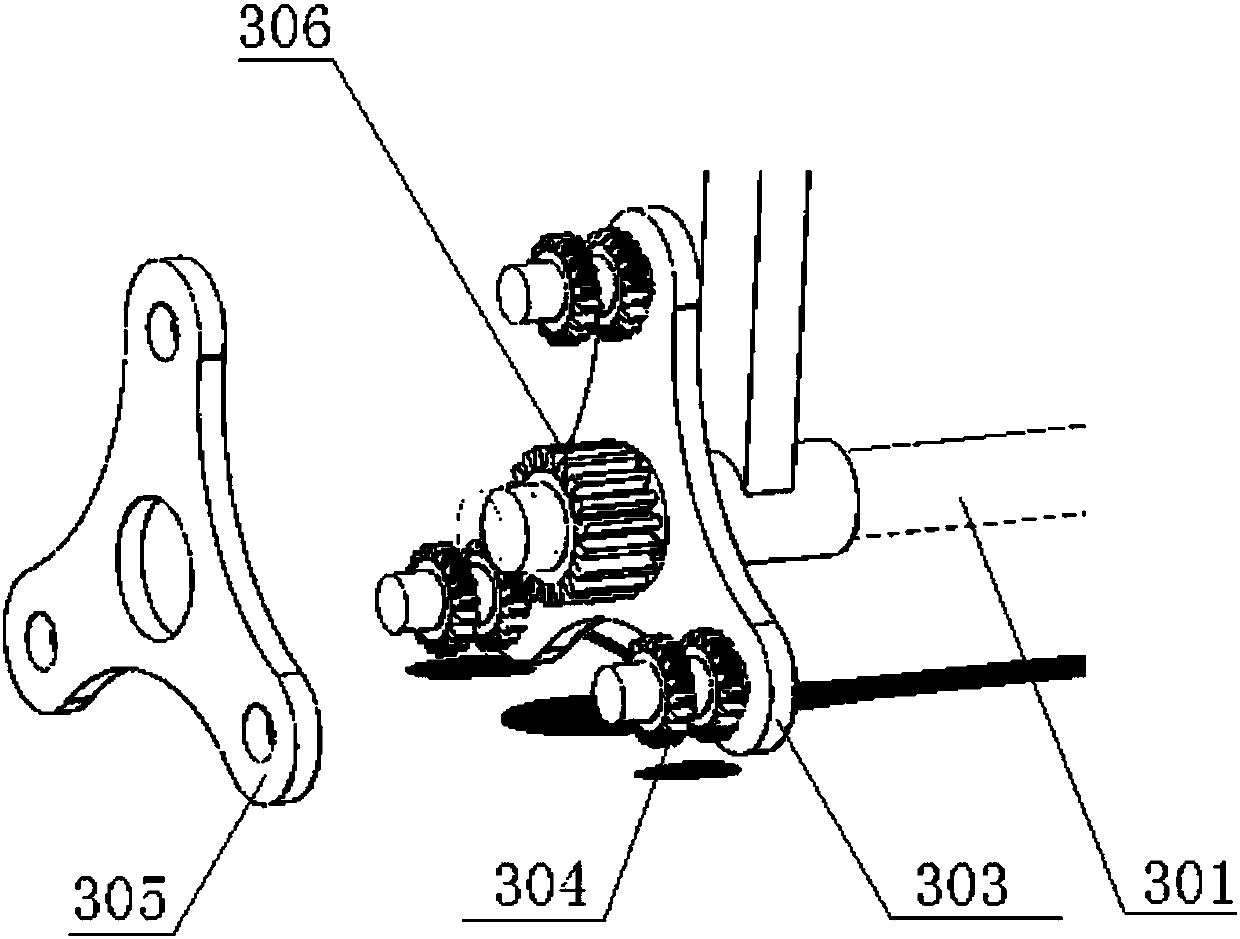

[0024] Such as figure 1 with figure 2 As shown, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com