Vibrating type marine hydrate pressure maintaining sampler

A sampler and hydrate technology, applied in the direction of sampling devices, etc., can solve problems such as low pressure retention rate, low success rate of pressure retention, and loss of flushing fluid, so as to improve the success rate of pressure retention and pressure retention rate, and improve the Good pressure sealing performance and core sequence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

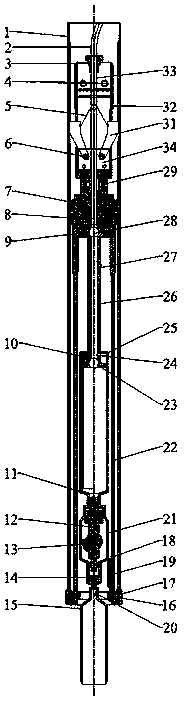

[0029] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention is composed of a positioning mechanism, a vibrating coring mechanism, a lifting mechanism, a flushing mechanism, and a pressure-holding mechanism. The sampler can be used for in-situ pressure-holding sampling of marine hydrate deposits, which can effectively reduce the disturbance to the sample. , to improve the success rate of holding pressure.

[0030] Positioning mechanism is made up of outer tube 1, bullet clip 31, bullet latch pin 6, tension spring 5, suspension ring 7, seat ring 8. After drilling into the hydrate-containing target layer, put the sampler into the sampler for coring, the cartridge is opened under the action of the tension spring 5, and the cartridge chamber composed of the outer tube 1 restricts the upward movement of the cartridge 31 to prevent the sampler from moving upwards ; The suspension ring 7 is located on the seat ring 8 to prevent the sampler from mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com