Range hood with axial-flow type wind wheel

A range hood, axial flow technology, applied in the field of range hoods with an axial flow wind wheel, can solve the problems of complex structure of the centrifugal wind wheel, reduce the working efficiency of the wind wheel, affect normal use, etc., and achieve simple structure , Easy disassembly and assembly, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

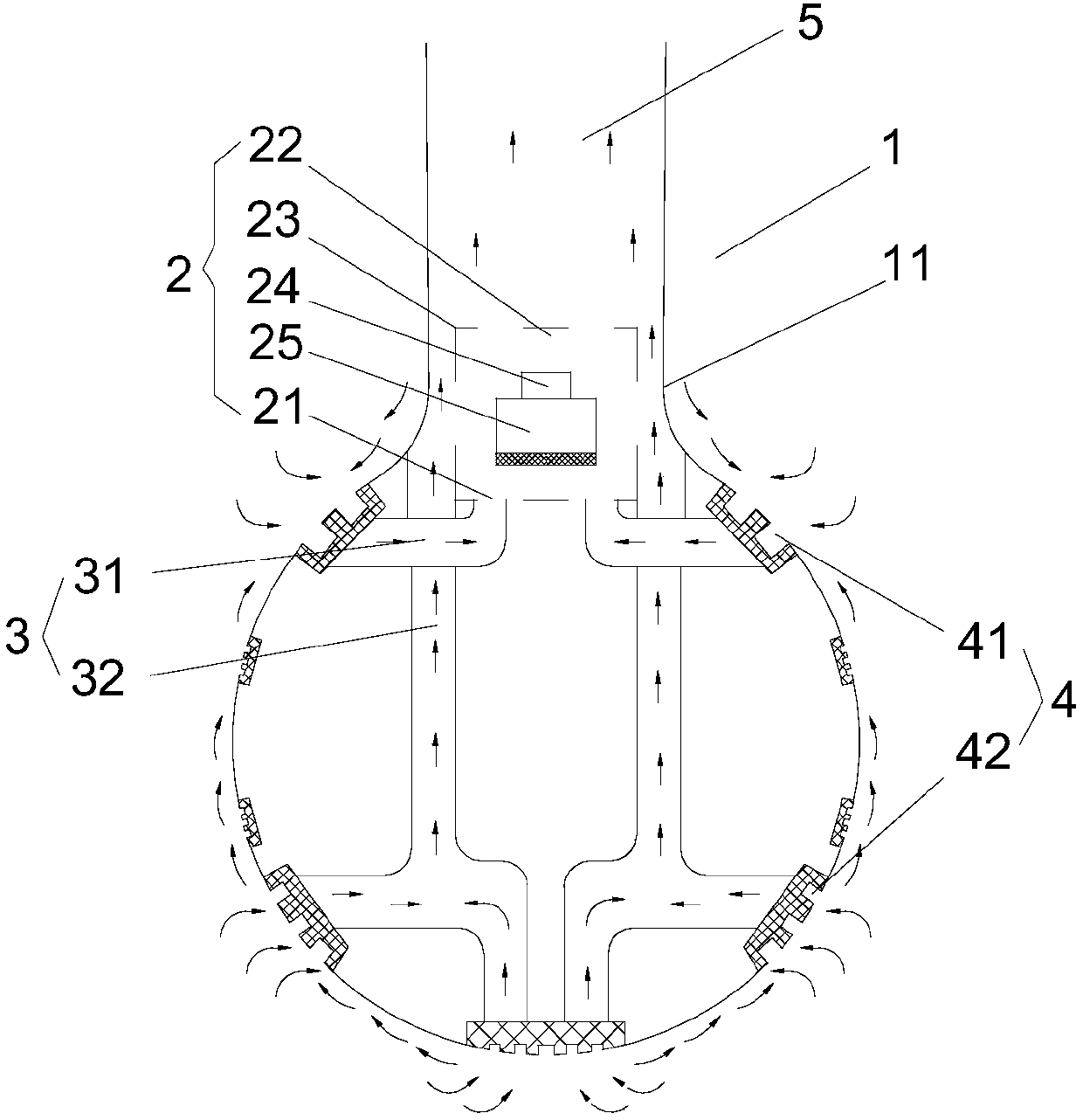

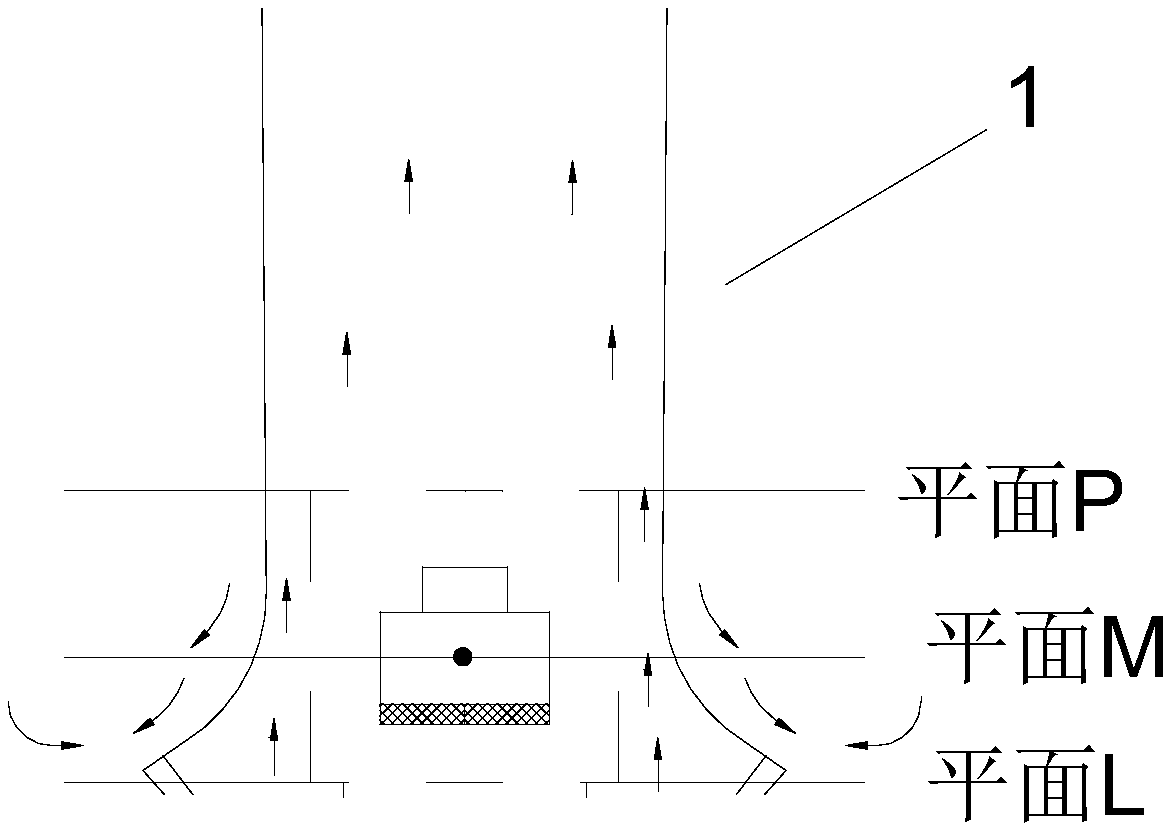

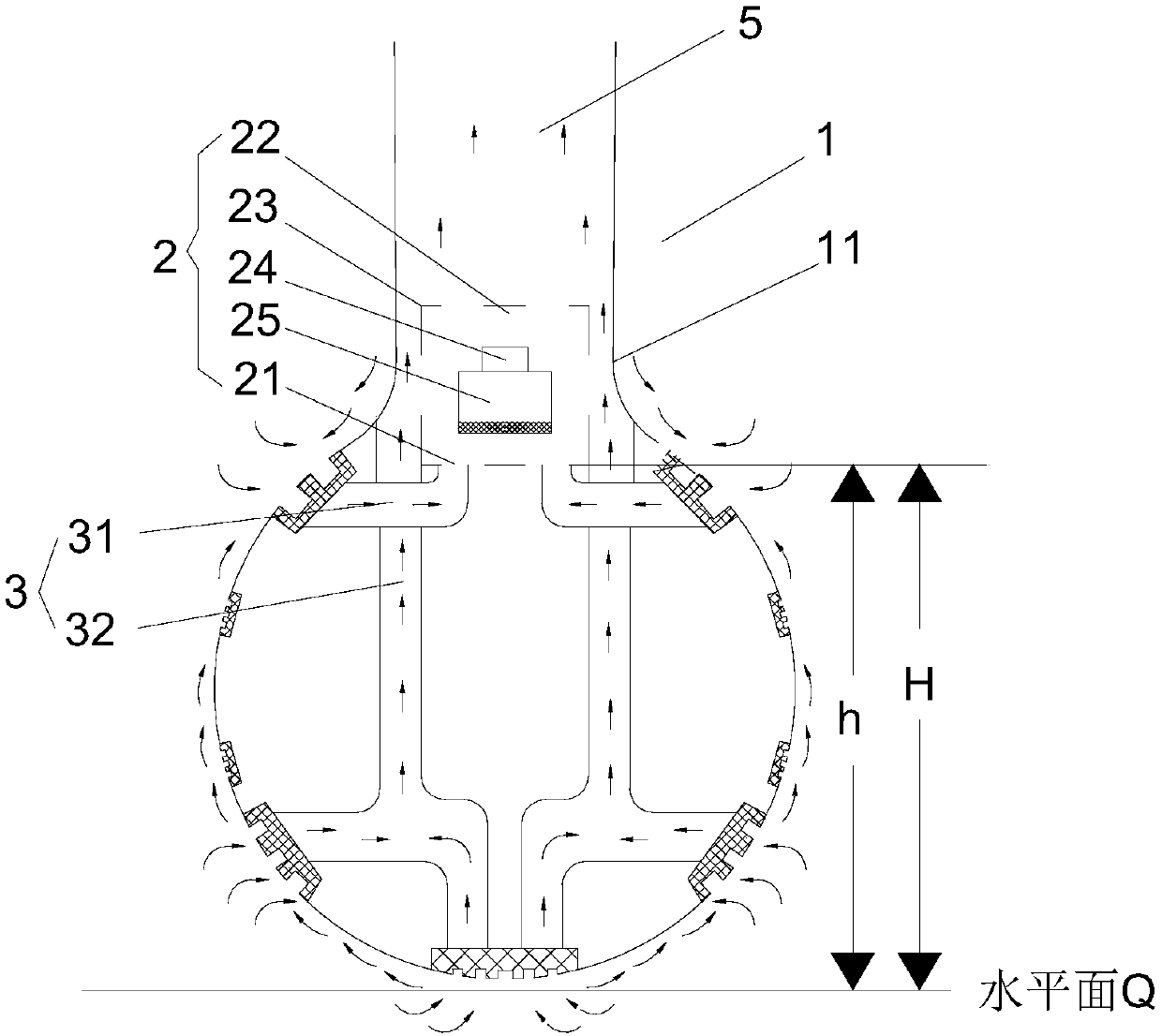

[0042] Such as Figure 1-4 As shown, a range hood with an axial-flow wind wheel is provided with a hood main body 1, and an axial-flow exhaust assembly 2 is installed inside the hood main body 1, and the plane L where the air inlet 21 of the exhaust assembly 2 is located is parallel to The plane P where the air outlet 22 is located.

[0043] The air inlet 21 and the air outlet 22 of the axial flow exhaust assembly 2 are parallel to each other, and the interior of the exhaust assembly 2 is a through cavity of a straight passage.

[0044] The internal assembly of the exhaust assembly 2 is as follows:

[0045] The exhaust assembly 2 includes a volute 23 , and the upper and lower surfaces of the volute 23 are correspondingly provided with outlet and air inlets 21 .

[0046] In order to improve the overall ventilation effect of the ventilation assembly 2 , the volute 23 is provided with an air outlet 22 and a plurality of air inlets 21 .

[0047] The multi-inlet 21 is used to in...

Embodiment 2

[0062] A range hood with an axial-flow wind wheel, other features are the same as in Embodiment 1, the difference is: as figure 1 As shown, in order to prevent the inside of the ventilation assembly 2 from being polluted, this embodiment does not pass the gas with soot into the inside of the ventilation assembly 2, effectively keeping the inside of the ventilation assembly 2 clean.

[0063] The air inlet 21 communicates with the air inlet group 4 of the hood main body 1 through the air duct 3 , and the air outlet 22 communicates with the exhaust duct 5 at the top of the hood main body 1 .

[0064] The air inlet group 4 is divided into a clean air inlet group and an oil fume air inlet group, and the clean air inlet group and the oil fume air inlet group are connected through an independent air duct 3 .

[0065] The upper air inlet channel 31 communicates with the clean air inlet group 41 and the air inlet 21 of the exhaust assembly 2 .

[0066] The lower air inlet duct 32 comm...

Embodiment 3

[0071] A range hood with an axial-flow wind wheel, other features are the same as in Embodiment 1, the difference is: as figure 1 As shown, in this embodiment, according to the principle of aerodynamics, the outer surface of the housing 11 of the main body of the hood 1 serves as a guiding surface for the moving direction of the oil fume, rather than forming a cover area for gathering the oil fume.

[0072] All outer surfaces of the casing 11 can be used as guiding surfaces, and the casing 11 does not include any platform structure such as a plane, an inclined plane or a non-planar surface, which is arranged above the cooktop.

[0073] There is at least one air inlet group 4 located in the non-covering area of the casing 11 .

[0074] According to the principle of aerodynamics, after the oil fume is generated, the oil fume will move along the outer surface of the housing 11 and be sucked into the air duct 3 inside the hood main body 1 by at least one air inlet group 4 provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com