Electric cabinet with square tube frame

A tube frame and electrical cabinet technology, applied in electrical components, substation/distribution device housing, substation/switch layout details, etc., can solve the problems of insufficient stocking, long procurement cycle, high cost, and achieve a wide range of applications and easy quality. Guaranteed, the effect of short construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

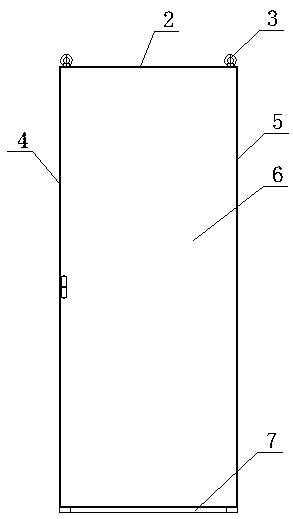

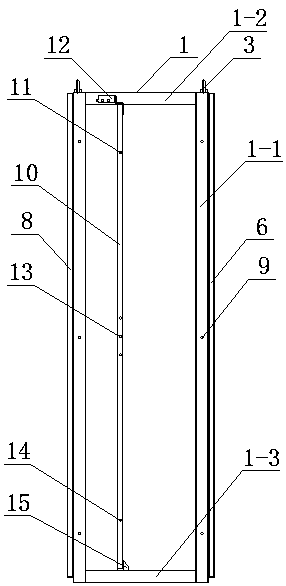

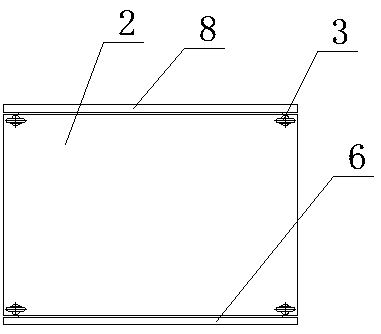

[0012] Such as figure 1 As shown in -6, the square tube frame electrical cabinet includes a square tube frame 1 welded by square tubes, and the left side panel 4, right side panel 5, rear door panel 8, top panel 2 and bottom panel 7 are connected to the square tube frame 1 , the front door panel 6 is also hinged on the square tube frame 1, and the suspension rings 3 are respectively fixedly connected on the four corners of the top plate 2.

[0013] The square tube frame 1 is welded by four square tube vertical bars 1-1, four square tube upper cross bars 1-2, four square tube lower bar 1-3, and four square tube vertical bar positions 1-1 On the four corners of the square tube frame 1, and on the outside of the left side plate 4 and the right side plate 5, the upper ends of the four square tube vertical bars 1-1 are connected by four square tube upper cross bars 1-2, four The lower end of the root square tube vertical bar 1-1 is connected by four square tube lower cross bars 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com