Three-station mechanism integrating manual operation and electric operation and with breaking trip

A three-position, tripping technology, applied in contact operating mechanisms, circuits, electrical switches, etc., can solve the problems of high manufacturing cost, unstable performance, complex structure, etc., and achieve long service life, reasonable and reliable structural design, High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

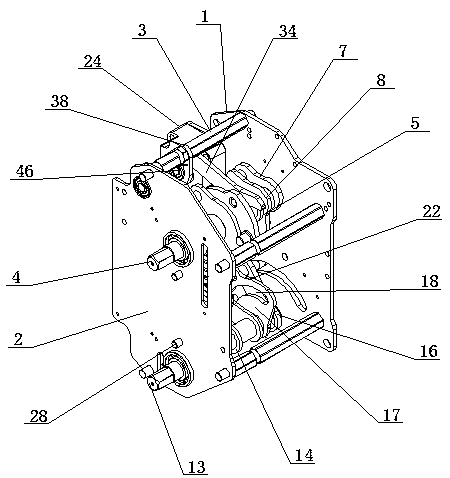

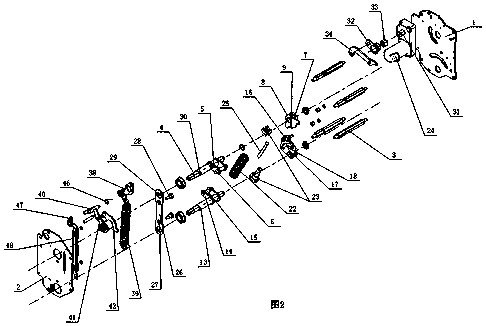

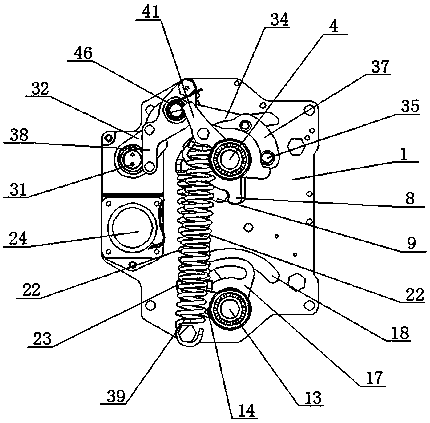

[0024] The specific embodiments of the present invention will be further described below with reference to the drawings.

[0025] A three-station mechanism with opening and tripping that integrates manual and electric operation. It includes a frame. The frame is equipped with an isolation transmission device, an isolation output device, a ground transmission device, a ground output device, an energy storage device, and an electric The driving device and the opening and tripping device. The electric driving device is connected to and drives the isolation transmission device through a one-way input. The isolation transmission device is connected to one end of the energy storage device and can be rotated by manual input or motor drive to drive the energy storage The device stores energy. When the energy storage device turns to the maximum energy storage position, the energy storage is released to drive the isolation transmission device to continue to rotate. At this time, the isolati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com