Static liquid level based liquid level alarm switch detection method and alarm line calibration method

A liquid level alarm and switch detection technology, applied in the direction of liquid/fluid solid measurement, measuring device, test/calibration device, etc., can solve problems such as easy deflection or unbalance, increase intermediate process, and unreliable measurement results, etc., to achieve Easy operation and high accuracy of measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

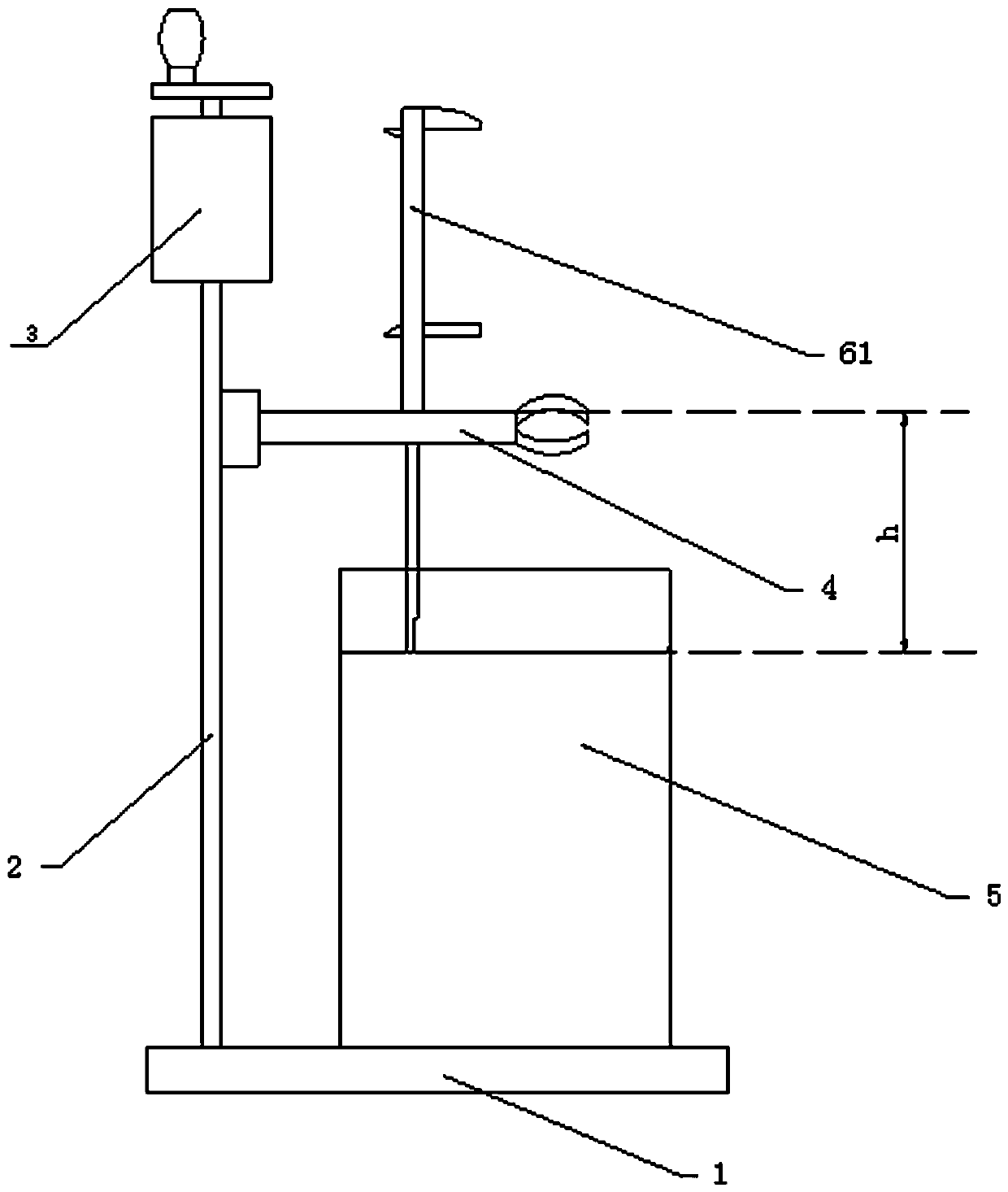

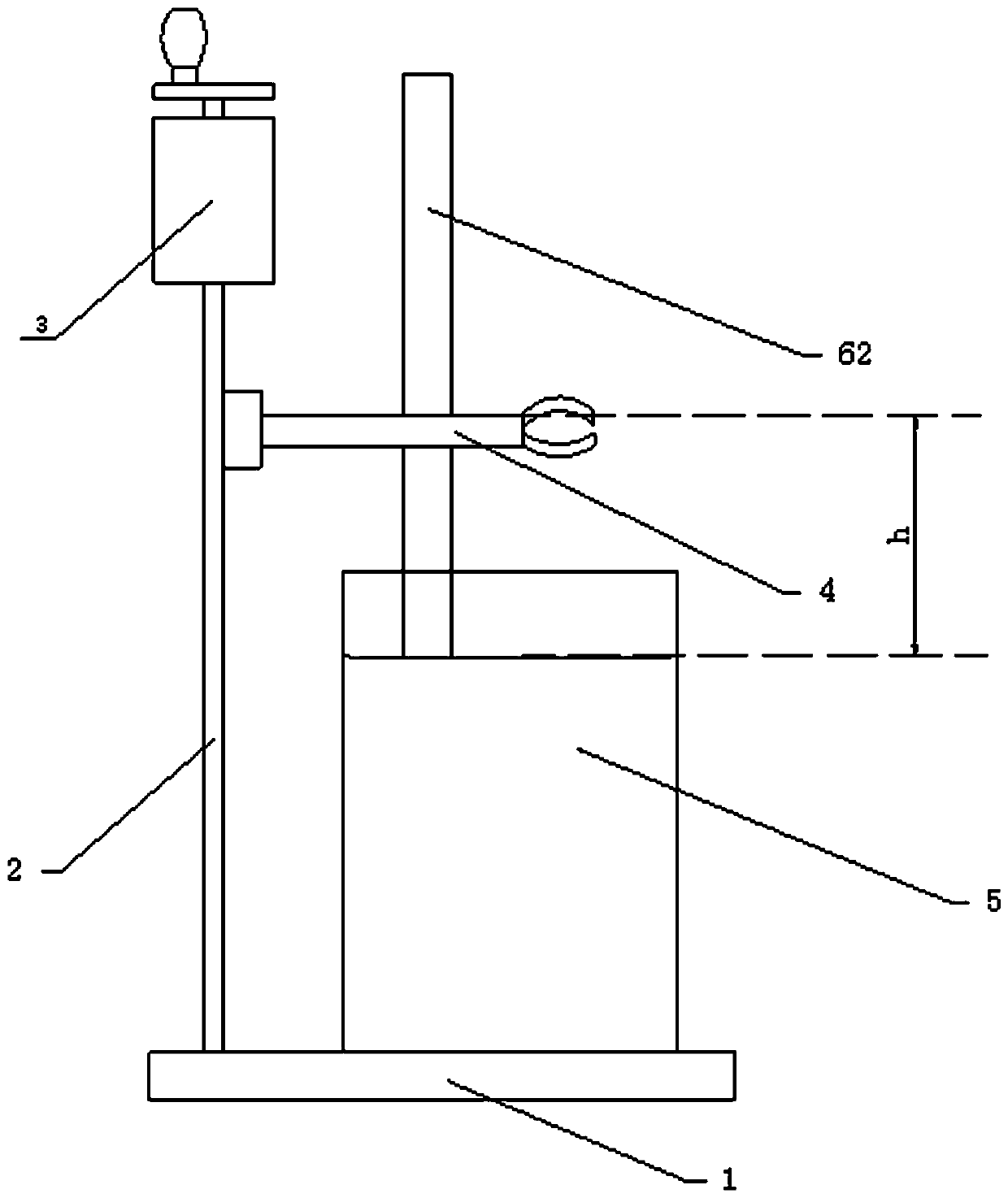

[0027] See attached figure 2 , The distance measuring device described in this embodiment adopts a ruler 62 . When the distance measuring device adopts a vernier caliper, a small hole that enables the ruler to pass through the liquid surface of the transparent container below can be set on the mounting frame. Other technical features of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0029] See attached image 3 , The distance measuring device described in this embodiment adopts a laser length measuring instrument 63 . When the distance measuring device adopts a laser length measuring instrument, one deck of reflective paper 7 floats on the liquid surface of the container. Other technical features of this embodiment are the same as those of Embodiment 1. When the position of the alarm line of the liquid level alarm switch is reached, that is, the switching state of the liquid level alarm switch is switched, the distance measuring device is used to automatically measure the calibration parameters of the alarm line of the liquid level alarm switch, and the measured liquid level alarm switch alarm line The calibration parameters are compared with the standard value, and the detection result is output to the alarm device, which is prompted by the alarm device. The distance measuring device is installed on the mounting frame of the vertical lifting device.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com