Device used for fracture exploitation

A cylinder block and inner diameter technology, which is applied in the field of oil exploration, can solve the problems of easy damage to the power end and the tight friction between the piston and the cylinder block, so as to reduce the friction force, reduce the load on the power end, and reduce the output load. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

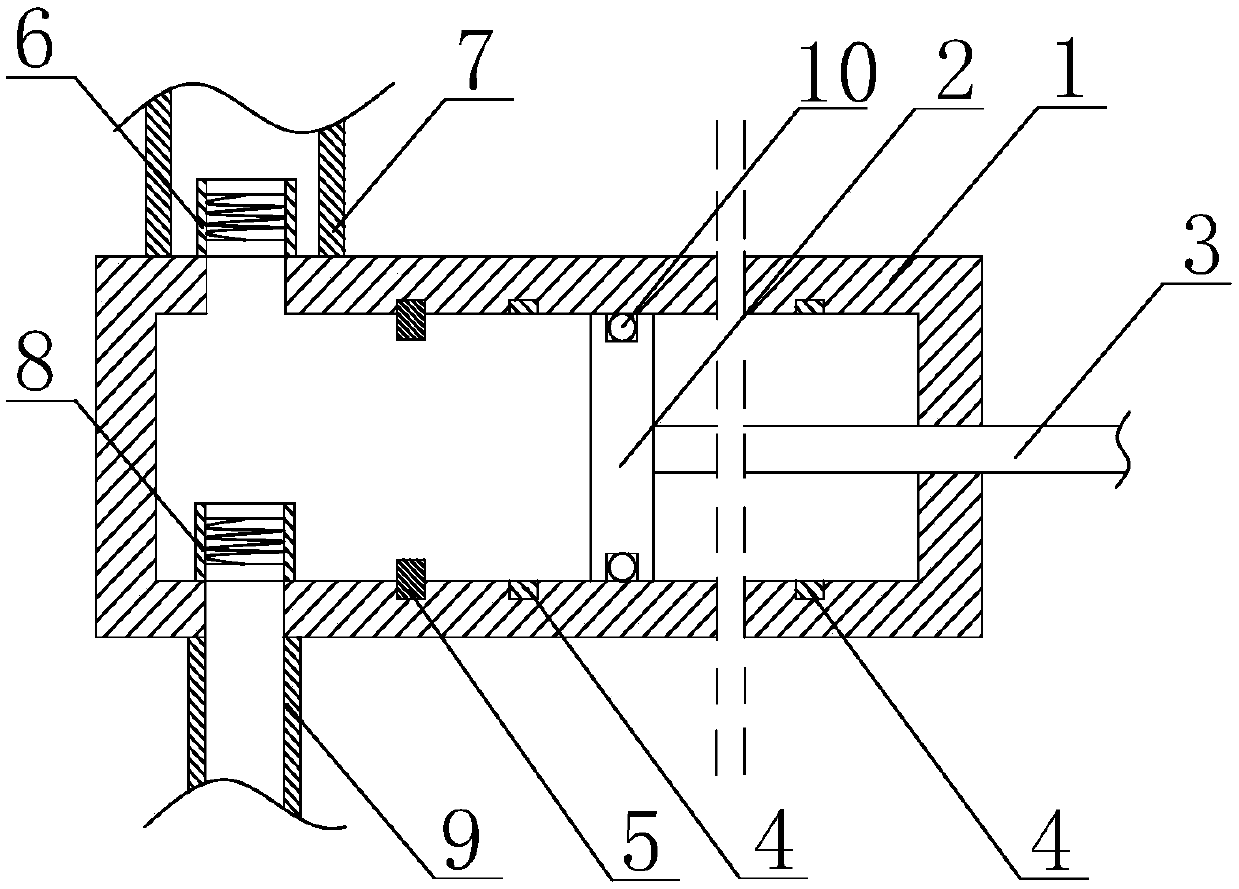

[0028] Such as figure 1The shown device for fracturing production includes a cylinder body 1 and a piston rod 3. One end of the piston rod 3 moves through one end face of the cylinder body 1 and is connected to a piston 2 located inside the cylinder body 1. The piston rod 3 The other end of the pump is connected to the power end of the fracturing pump; the cylinder body 1 is provided with a feed port and a discharge port, and a suction valve 8 is arranged above the feed port, and the cylinder body 1 communicates with the feed pipe 9 through the feed port. A discharge valve 6 is arranged above the discharge port, and the cylinder body 1 communicates with the discharge pipe 7 through the discharge port. The inner surface of the cylinder body 1 is provided with a number of first grooves, and also includes a limit valve matching the first grooves. Pad 5 and some filling pads 4, the height of the limit pad 5 is greater than the height of the first groove, the height of the filling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com