Paper folder with breathable mesh type paper stacking platform

A technology of ventilating mesh and origami machine, which is applied in the direction of folding thin materials, thin material processing, and object separation, etc., can solve the problems of large drawing resistance, multiple sheets, multiple sheets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in detail below by specific embodiment:

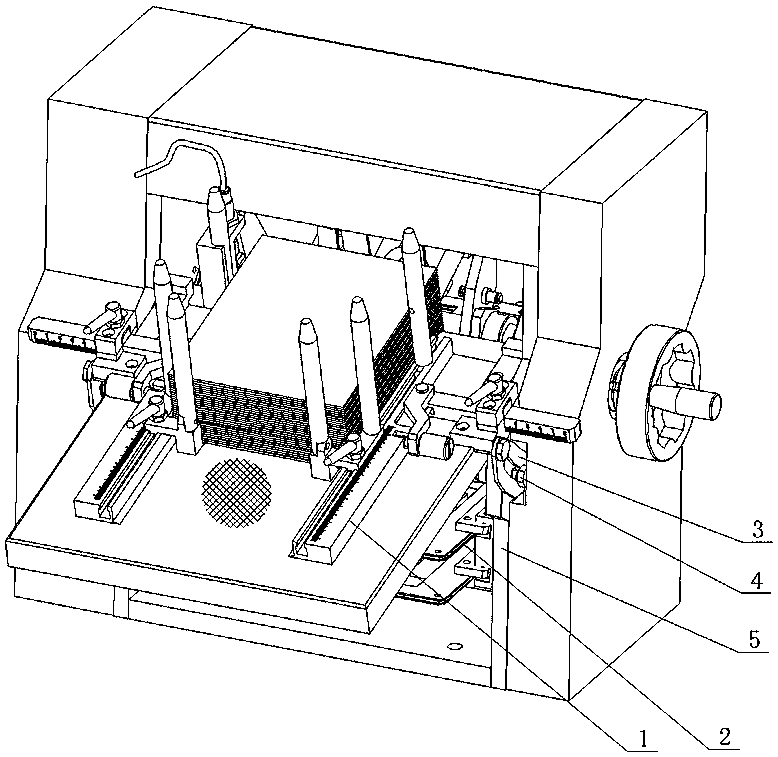

[0013] As shown in the figure, the air-permeable textured stacking table folding machine of the present invention includes a stacking mechanism 1 and a folding mechanism 2, and a vacuum suction nozzle is arranged between the two to extract the paper from the stacking mechanism 1 and send it to the folding mechanism 2. The paper stacking mechanism 1 includes a paper stacking platform 7 and a plurality of limit columns 8 installed on the paper stacking platform 7. A paper stop space is enclosed between each limit column 8, and paper A is stacked up and down in the paper stop space. The platform surface of the paper stacking platform 7 is provided with air-permeable texture 11, and air is injected between the air-permeable texture 11 and the bottom sheet of paper stacked up and down in the paper blocking space, and the air-permeable texture 11 can be directly engraved on the surface of the platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com