Automatic rotating spinning cake vehicle putting device

An automatic rotary and silk cake car technology, which is applied in the field of silk cake cars, can solve the problems of high labor intensity of operators, accumulation of silk cakes, and reduced production efficiency, so as to improve the degree of automation and integration, and reduce auxiliary frequency and time , the effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

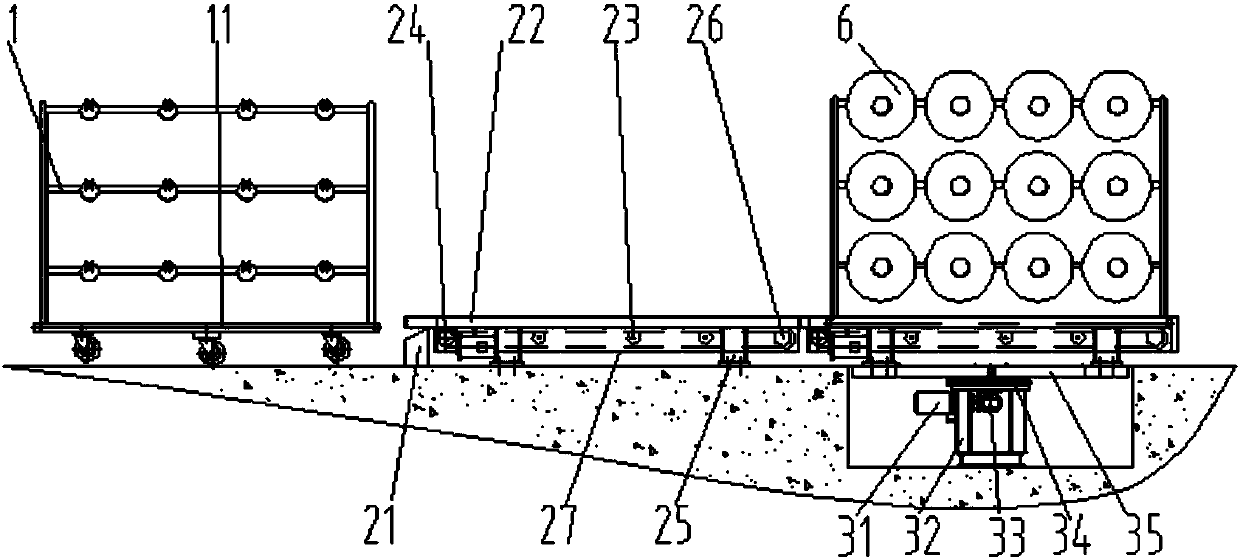

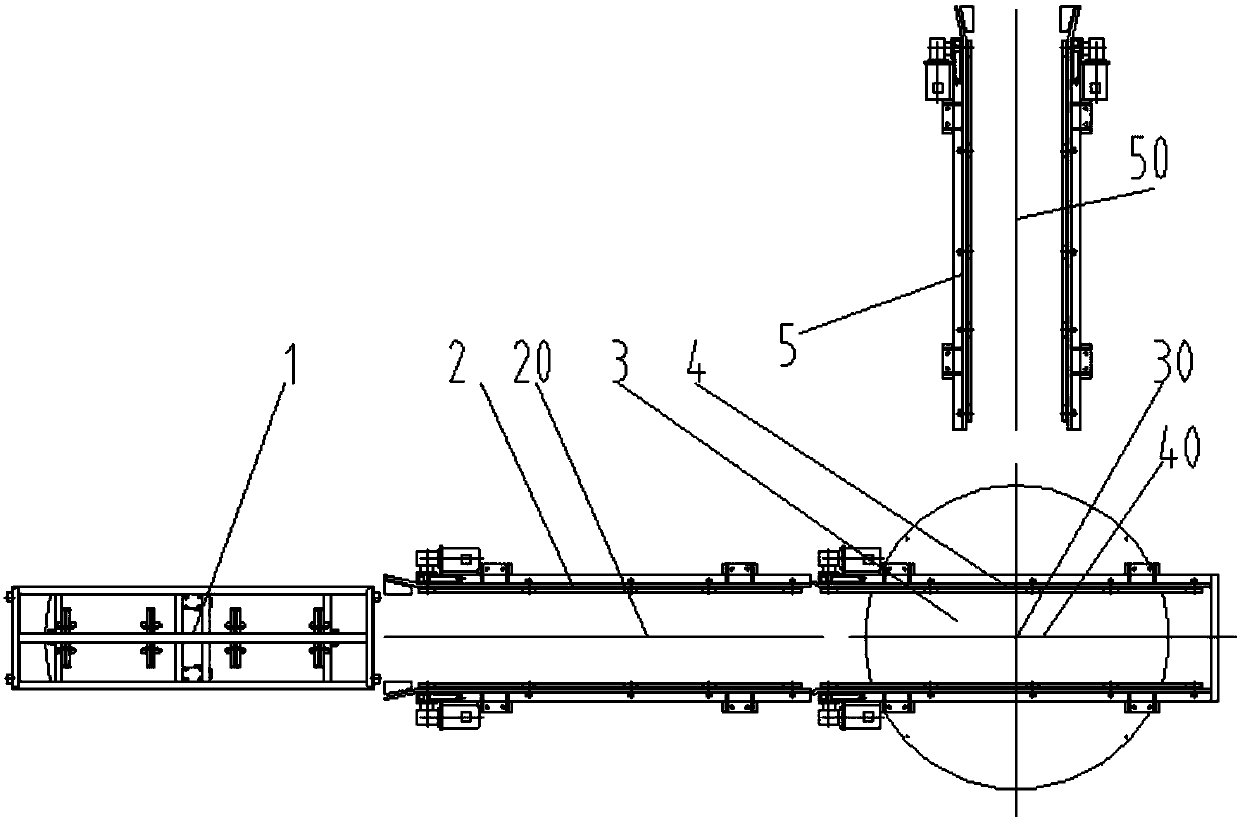

[0027] Embodiment: a kind of automatic rotary put silk cake car device, such as figure 1 , 2 As shown, it includes a yarn cake car 1, an automatic rotary platform 3, a device for placing a yarn cake car 4, an empty yarn cake car buffer device 2, and a full yarn cake car buffer device 5, wherein the empty yarn cake car buffer device 2 is used to store Empty silk cake car, and full silk cake car cache device 5 is used for depositing full silk cake car.

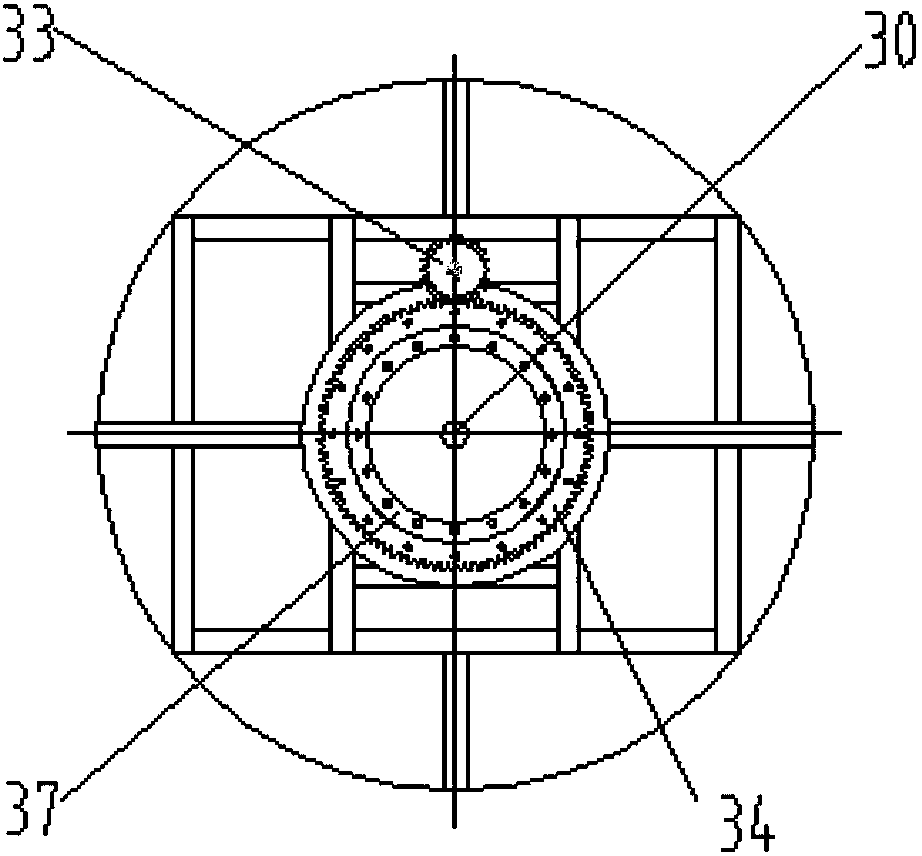

[0028] The automatic rotary platform 3 performs a rotary motion of not less than 180° with the platform rotary center 30, so as to realize the full silk cake throwing on both sides of the silk cake car 1. The silk cake car placement device 4 is fixed on the automatic rotary platform 3, and the silk cake car 1 is tightened and positioned through the silk cake car placement device 4 to ensure that the silk cake 6 is accurately thrown onto multiple spindle positions of the silk cake car 1. Empty yarn car buffer device 2 and full ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com