Full-automatic stripping, cooling, blow-drying and pelletizing production line

A fully automatic, production line technology, applied in the direction of coating, etc., can solve problems such as inconvenient use, unreasonable structural design, etc., and achieve the effect of improving performance and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

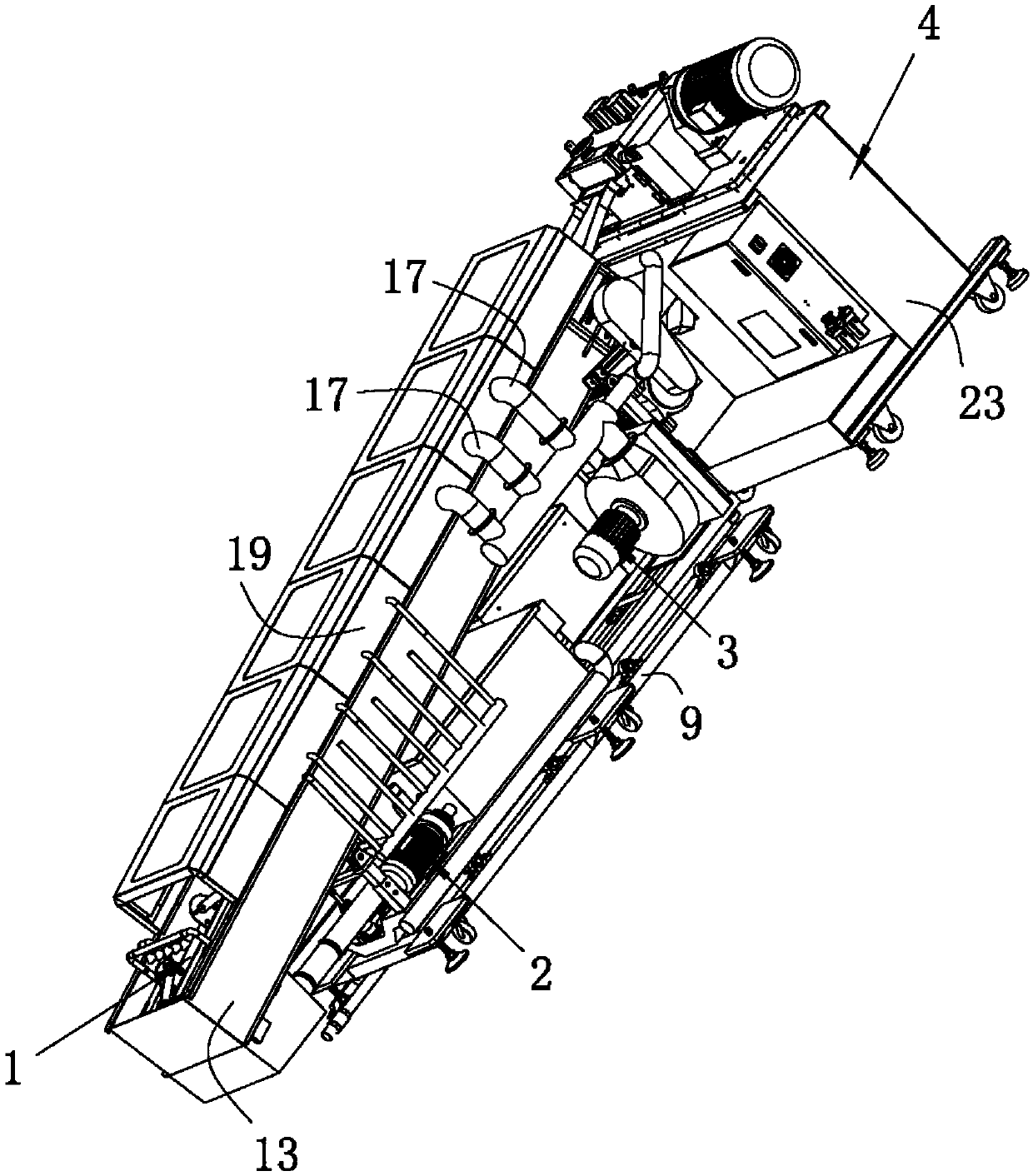

[0040] see Figure 1 to Figure 5 As shown, a kind of full-automatic strand cooling, drying and pelletizing production line of the present invention comprises a strand mechanism 1, a cooling mechanism 2, a drying mechanism 3 and a pelletizer 4, and the strand mechanism 1 is used to convey extruded The material strip after extruding molding by machine, the cooling mechanism 2 utilizes cooling liquid to cool the material strip conveyed by the pulling mechanism 1, the drying mechanism 3 utilizes the flowing air to blow dry the material strip cooled by the cooling mechanism 2, and the pelletizer 4 is used for The material strip after cutting blow-drying mechanism 3 dries; Described granu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com