Six-roll applicator suitable for producing plywood by aid of soybean adhesive with medium and low viscosity

A soybean adhesive and plywood technology is applied in the directions of adhesive application devices, wood processing appliances, manufacturing tools, etc., to achieve the effects of improving the bonding effect, reducing the cost of the adhesive, and promoting production and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

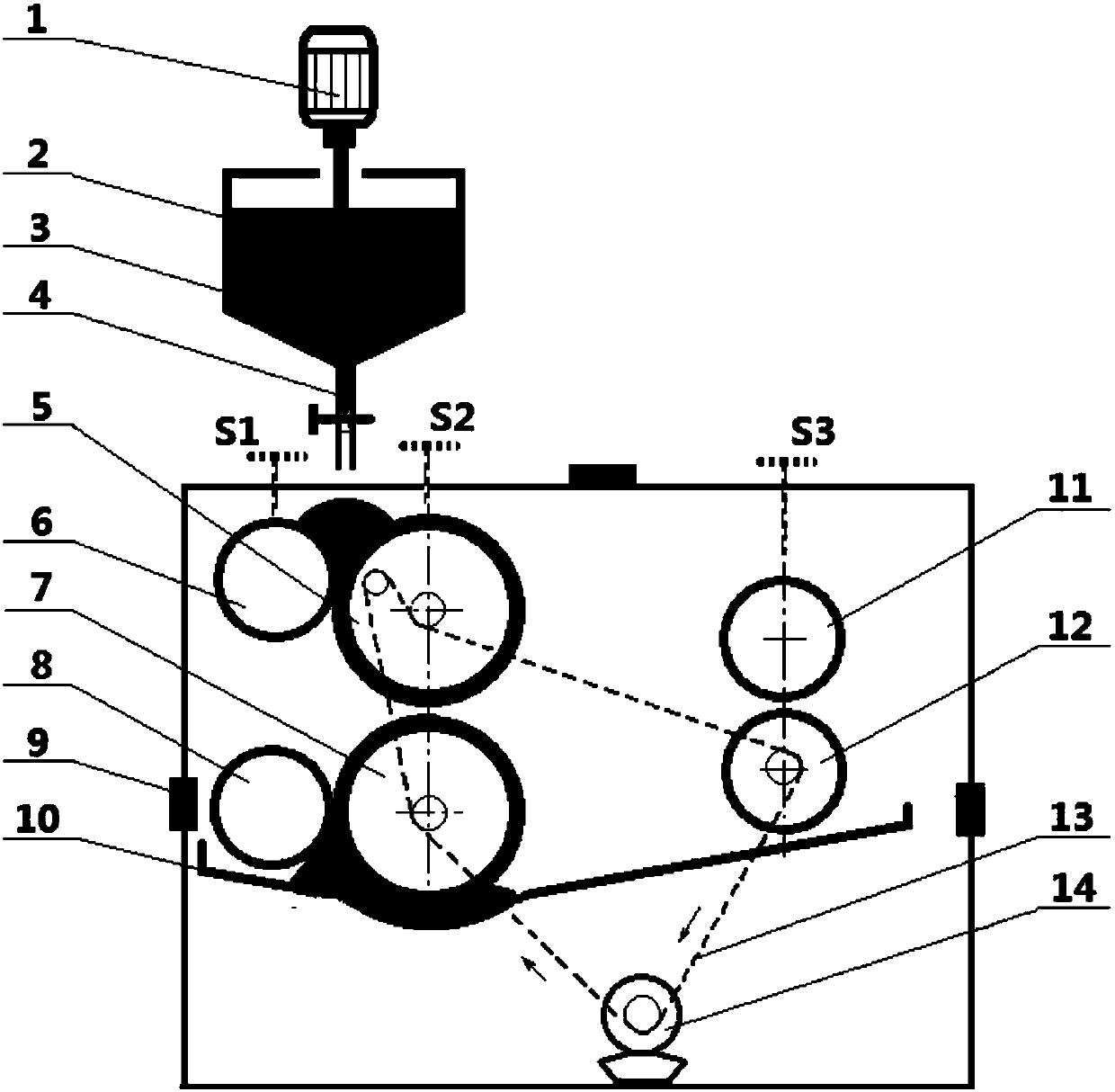

[0015] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, a six-roller gluing machine suitable for producing plywood with medium and low viscosity soybean adhesives described in this embodiment includes a glue release assembly, a frame 9, a rubber storage tank 10, a deep groove rubber roller assembly, The grooved rubber roller assembly, the chain 13 and the drive motor 14, the rubber storage tank 10 are installed on the frame 9, and the deep groove rubber roller assembly and the non-grooved rubber roller assembly are installed side by side above the rubber storage tank 10, The glue release assembly is arranged above the deep groove rubber roller assembly, and the driving motor 14 is installed on the bottom of the frame 9, and the driving motor 14 is connected with the deep groove rubber roller assembly and the non-grooved rubber roller through a chain 13 Component connections.

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, a deep-grooved rubber roller assembly suitable for a six-roll gluer for producing plywood with medium and low-viscosity soybean adhesives described in this embodiment includes an upper deep-groove rubber roller 5 and a lower deep-groove rubber roller 7, The upper deep groove rubber roller 5 and the lower deep groove rubber roller 7 are arranged sequentially from top to bottom. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 and figure 2 To illustrate this embodiment, a deep-grooved rubber roller assembly suitable for a six-roller gluer for producing plywood with medium and low viscosity soybean adhesives in this embodiment also includes an upper non-grooved rubber roller 11 and a lower non-grooved rubber roller 11 The roller 12, the upper rubber roller 11 without grooves and the lower rubber roller 12 without grooves are arranged in sequence from top to bottom. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com