Ceramic electronic component and preparation method thereof

A technology of electronic components and ceramics, which is applied in the field of ceramic electronic components and its preparation, can solve problems such as difficulty in identifying ceramic bodies, difficulty in identifying ceramic bodies, and inconsistent performance of ceramic electronic components, so as to avoid structural integrity and prevent insufficient suction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

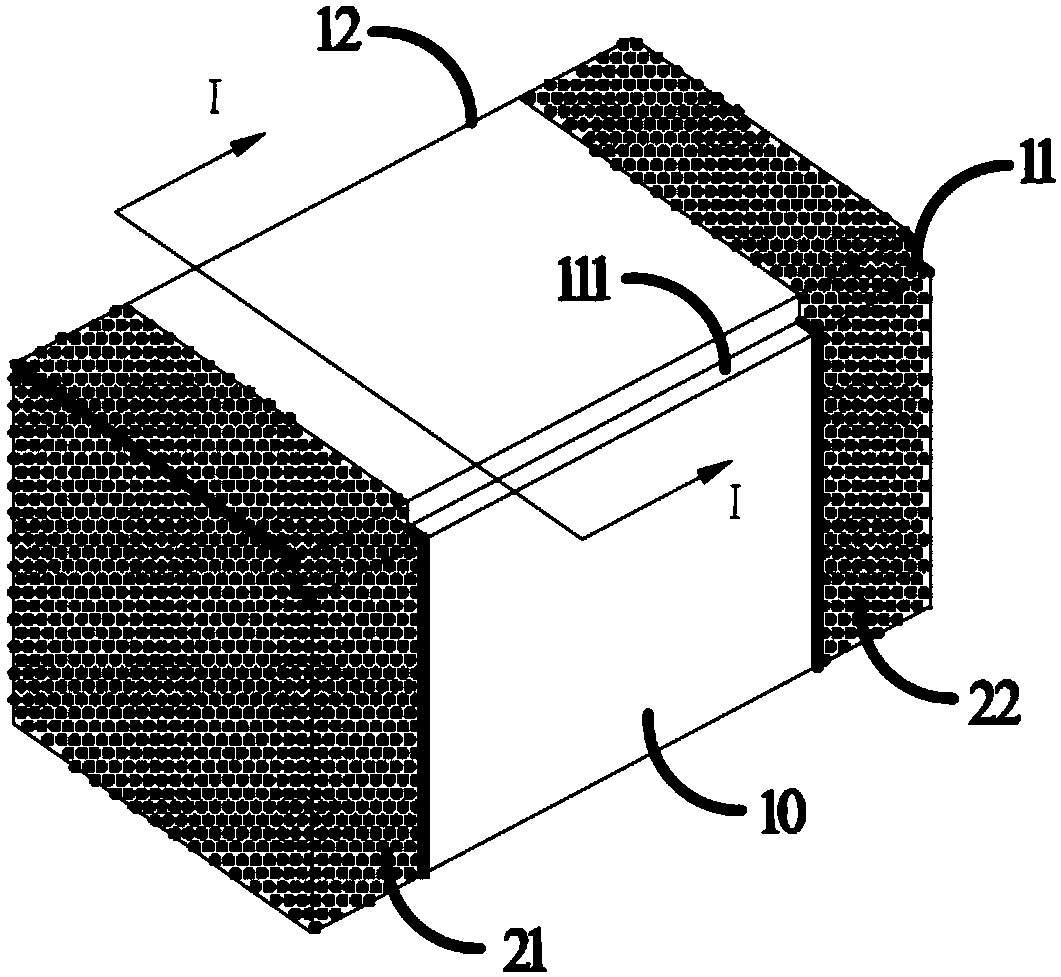

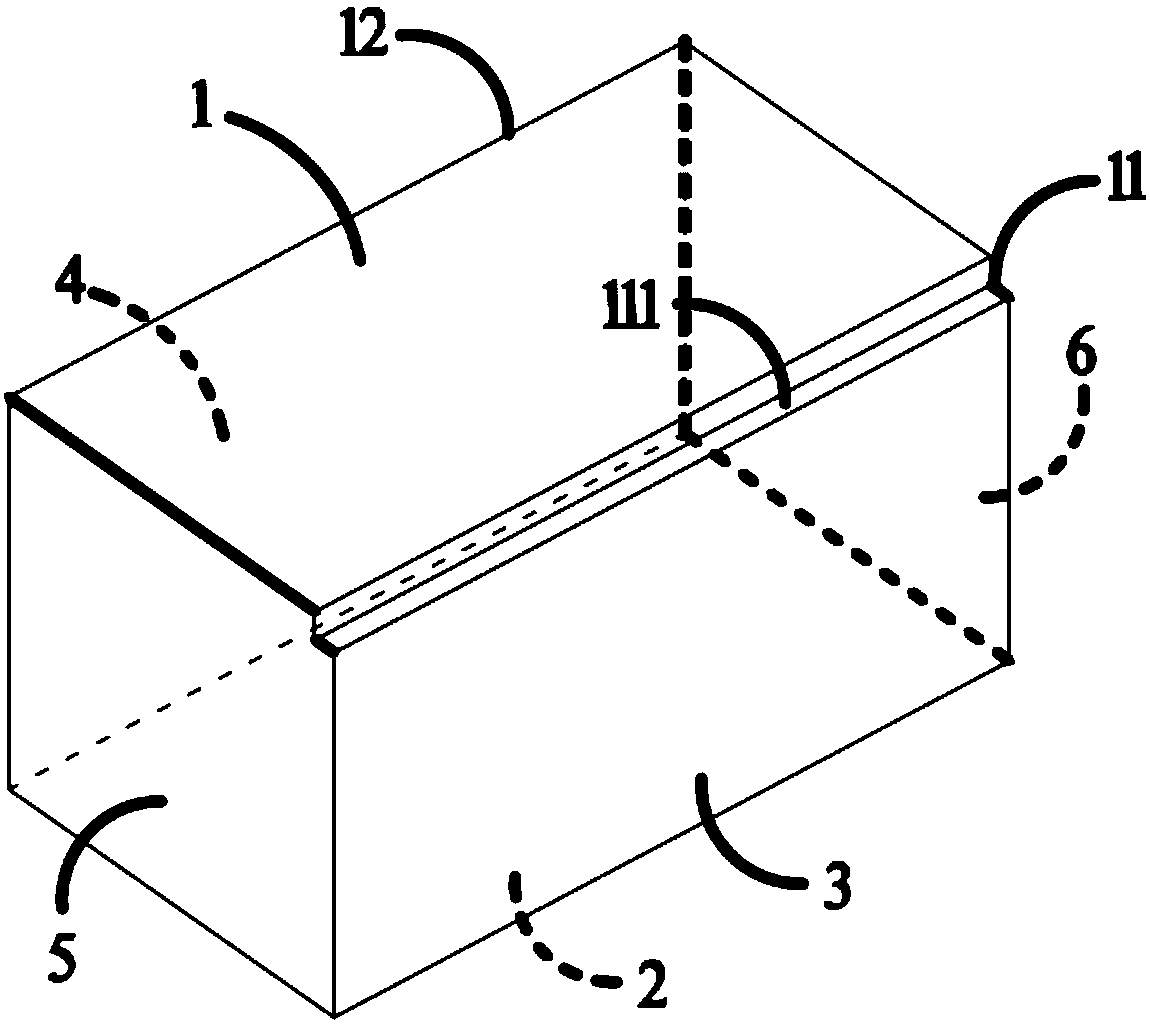

[0034] Such as figure 1 , figure 2 and image 3 As shown, a ceramic electronic component according to an embodiment of the present invention includes a ceramic body 10, the ceramic body 10 is a rectangular body, and includes a first side 1 and a second side 2 opposite to each other, and a third side opposite to each other. 3 and the fourth side 4 and the first end face 5 and the second end face 6 opposite to each other; the first side 1 and the second side 2 are perpendicular to the thickness direction of the ceramic body 10, and the third side 3 and the fourth side 4 are perpendicular to the thickness direction of the ceramic body 10. The width direction of the ceramic body 10 is perpendicular, the first end face 5 and the second end face 6 are perpendicular to the length direction of the ceramic body 10; the edge at the intersection of the first side 1 and the third side 3 is the first edge 11, the second The edge at the intersection of one side 1 and the fourth side 4 is...

Embodiment 2

[0071] A ceramic electronic component in this embodiment of the present invention differs from the ceramic electronic component in Embodiment 1 only in that in this embodiment, the length of the first groove 111 is shorter than the length of the first edge 11 .

[0072] The position of the first groove 111 on the first edge 11 is not particularly limited, but in order to facilitate identification of each side of the ceramic electronic component, the first groove 111 is not completely covered by the first terminal electrode 21 and the second terminal electrode 22 .

Embodiment 3

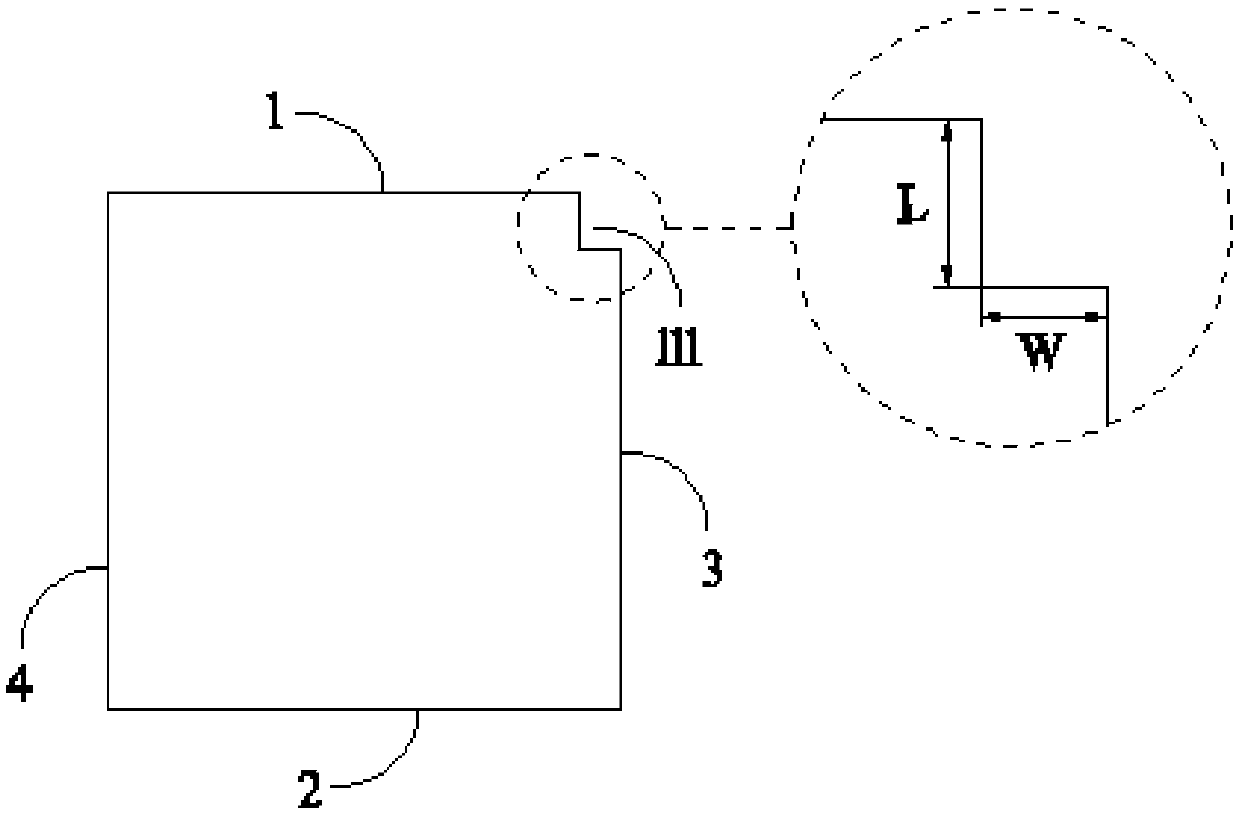

[0074] Such as Figure 4 As shown, a ceramic electronic component in the embodiment of the present invention differs from the ceramic electronic component in Embodiment 1 in that: in this embodiment, the second edge 12 is provided with a second groove 112; The depth of the section of the groove 111 on the first side 1 is L 1 , the depth of the section of the first groove 111 on the third side 3 is W 1 , the depth of the section of the second groove 112 on the first side 1 is L 2 , the depth of the section of the second groove 112 on the fourth side 4 is W 2 ; L 1 , W 1 , L 2 and W 2 all the same or different.

[0075] It should be noted that, in this embodiment, the first groove 111 and the second groove 112 are both arranged on the two lengthwise edges of the first side surface, in fact, the first groove and the second groove It can also be arranged on the edges in the two length directions of the third side.

[0076] Further, the vertical section of the second groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com