Code scanning technology based spare part full life circle tracking method

A technology of full life cycle and spare parts, which is applied in the field of full life cycle tracking of spare parts based on scanning code technology, can solve the problems of spare parts operation and processing limited to paper records, scattered responsibility for spare parts storage, and hidden dangers of company safety production, etc. , to achieve standardized management, ensure safety and stable production, and strengthen centralized and unified management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

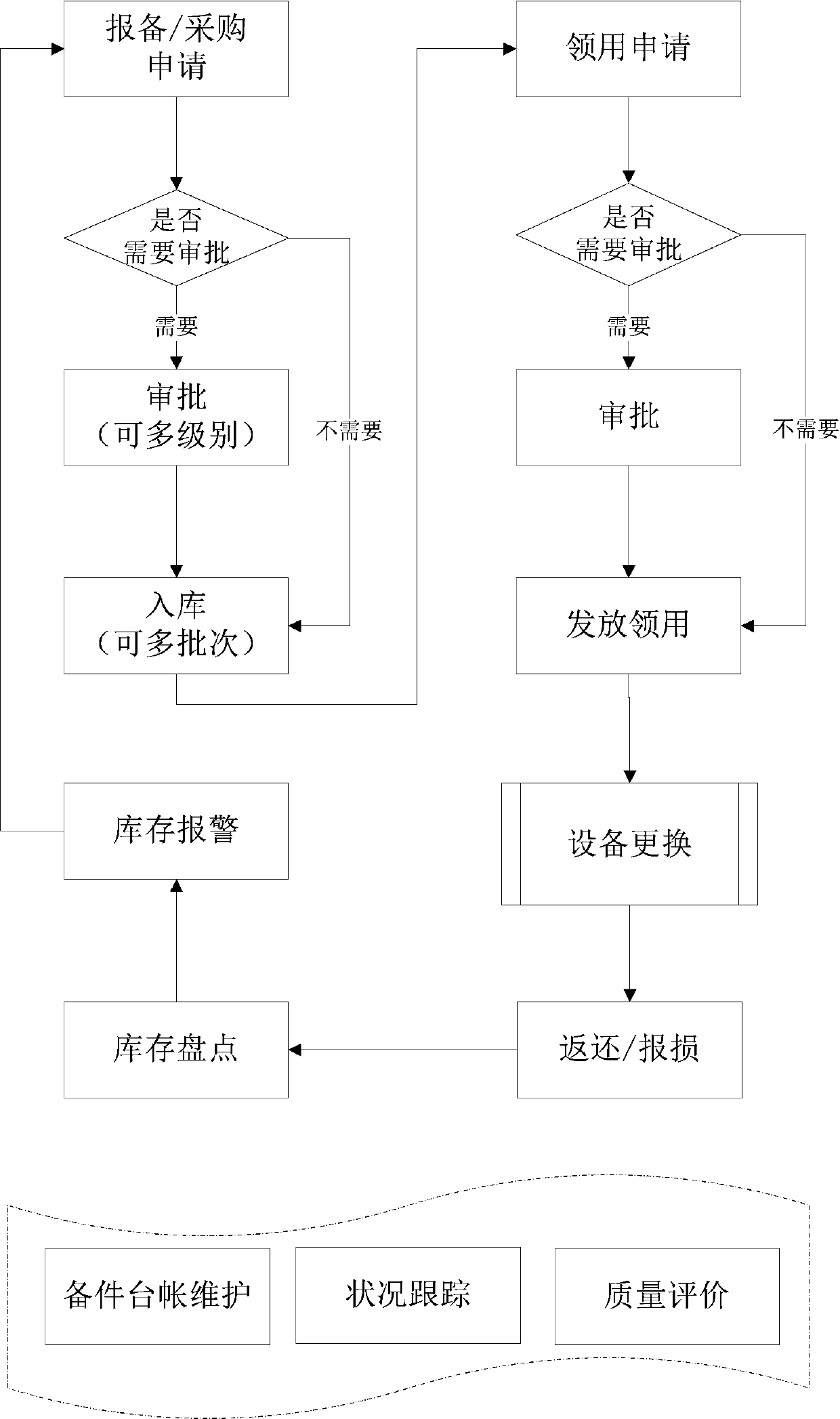

[0036] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0037] The management of spare parts mainly includes: spare parts storage management, inventory management and supplier management. Among them, the management of spare parts in and out of the warehouse includes the procedures of filing application, warehousing, requisition, and return of spare parts; the inventory management of spare parts includes inventory counting and inventory warning; the management of spare parts suppliers includes the spare parts tables of each supplier Account maintenance, quality evaluation, etc.

[0038] Such as figure 1 Shown, the present invention comprises the following steps:

[0039] 1. Application for spare parts filing

[0040] According to the on-site production needs of the "four lines and one warehouse" of the measurement center, each operation and maintenance manufacturer or production departm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com