Compressor unit

A compressor and compressed air technology, which is applied to pump devices, measuring devices, mechanical equipment, etc., can solve the problems of open exhaust port, small exhaust port opening area, poor responsiveness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] Hereinafter, an embodiment of the present invention will be described in detail.

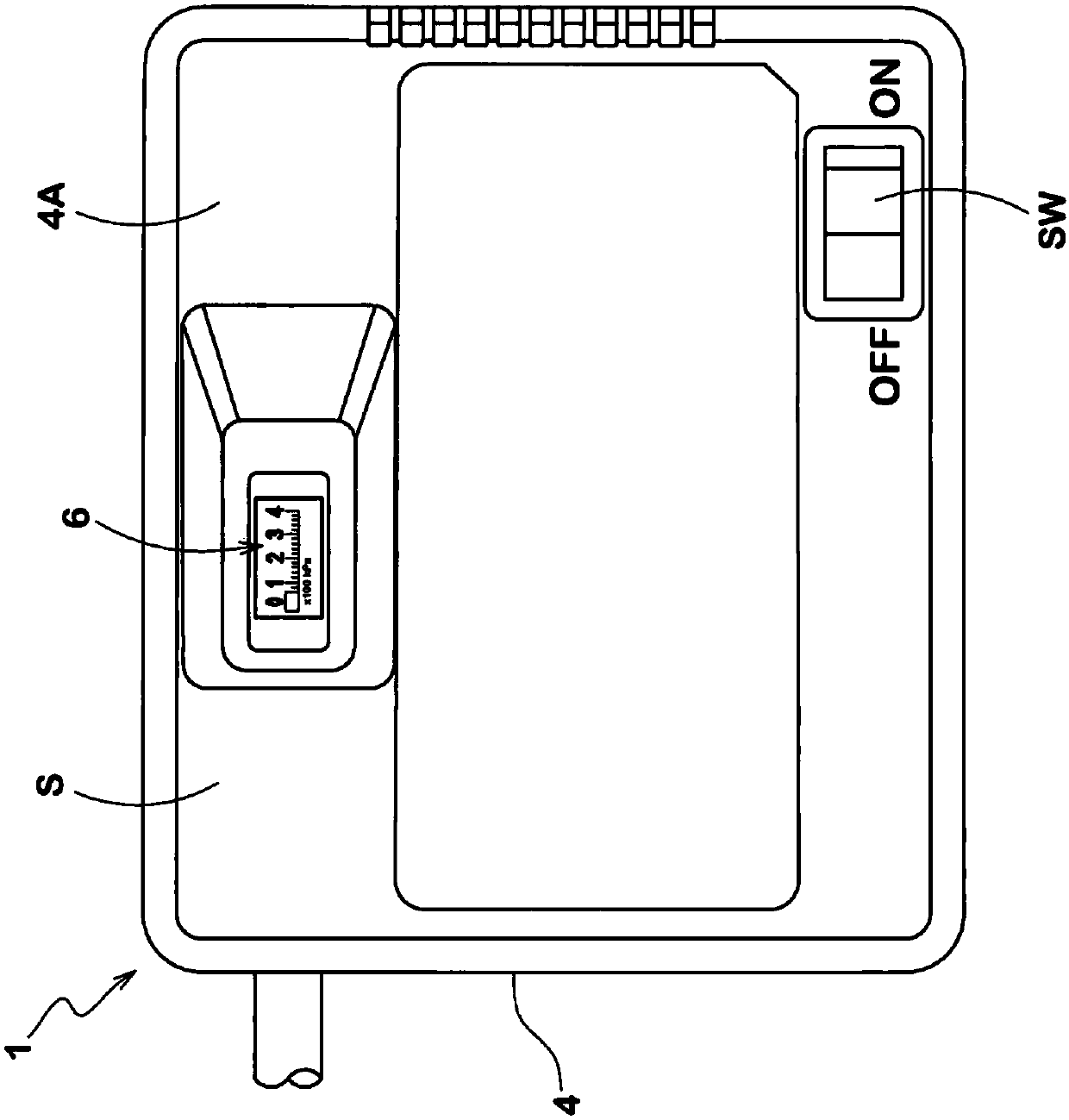

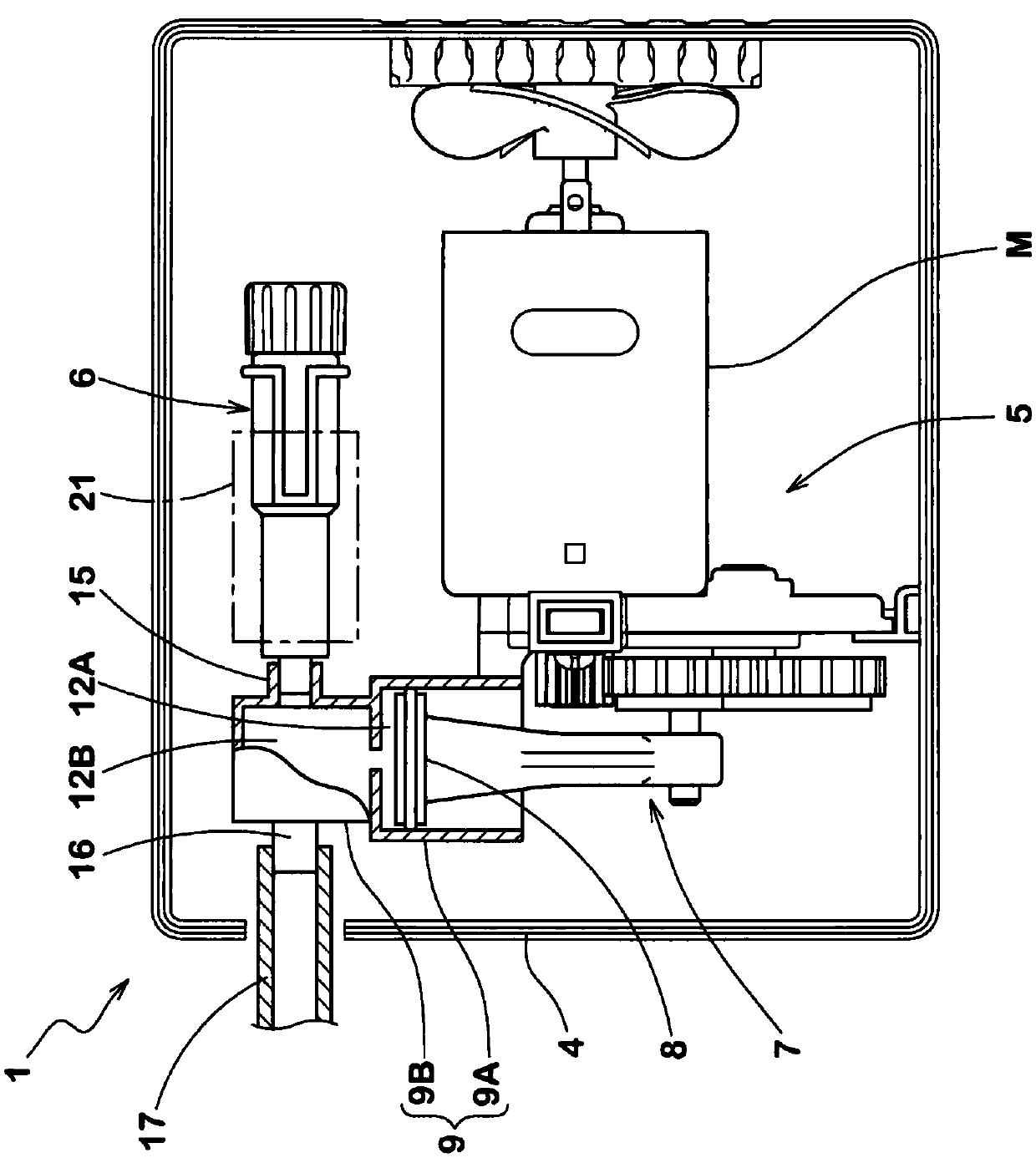

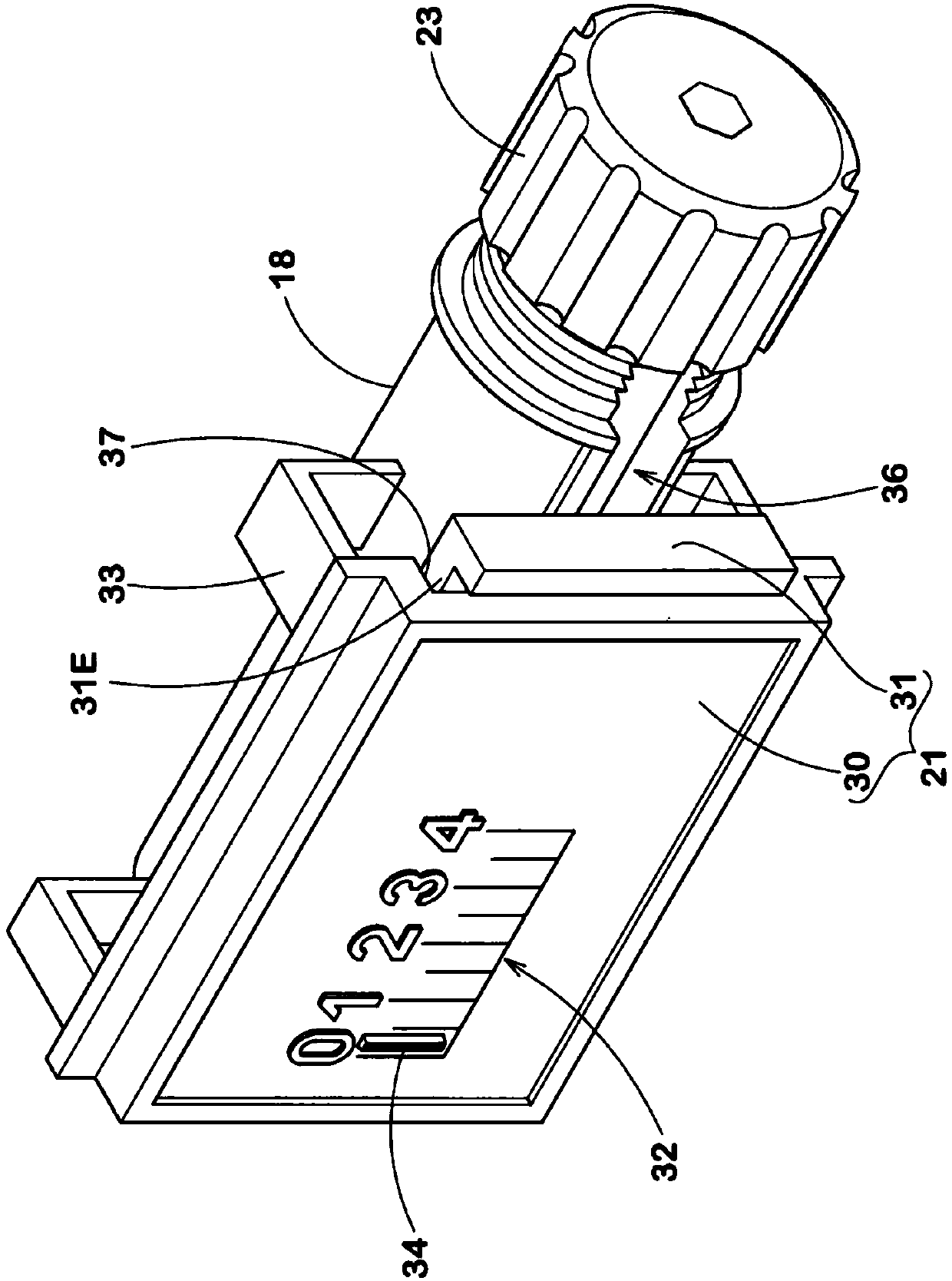

[0062] like figure 1 , 2 As shown, the compressor device 1 includes at least a compressor main body 5 for generating compressed air and a pressure gauge 6 for measuring the pressure of the compressed air in a storage case 4 .

[0063] The compressor main body 5 can appropriately adopt a known structure. The compressor main body 5 of this example includes an electric motor M, a piston 8 connected to the electric motor M via a crank mechanism 7 , and a cylinder 9 for accommodating the piston 8 so as to be capable of reciprocating movement. As the motor M, various DC motors on the market that operate from a 12V DC power supply of an automobile can be used. A power cord provided with a power spark plug connectable to an ignition socket of a car at the tip is connected to the motor M via a power switch SW attached to the upper plate portion 4A of the housing case 4 .

[0064] The cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com