Malt making process and detection method of new-flavor malt for Pilsener beer

A detection method and flavor technology, which is applied in the malting process and detection field of new flavor Pilsner beer malt, can solve the problems of rising costs, achieve the effects of reduced water consumption, reduced processing costs, and increased selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

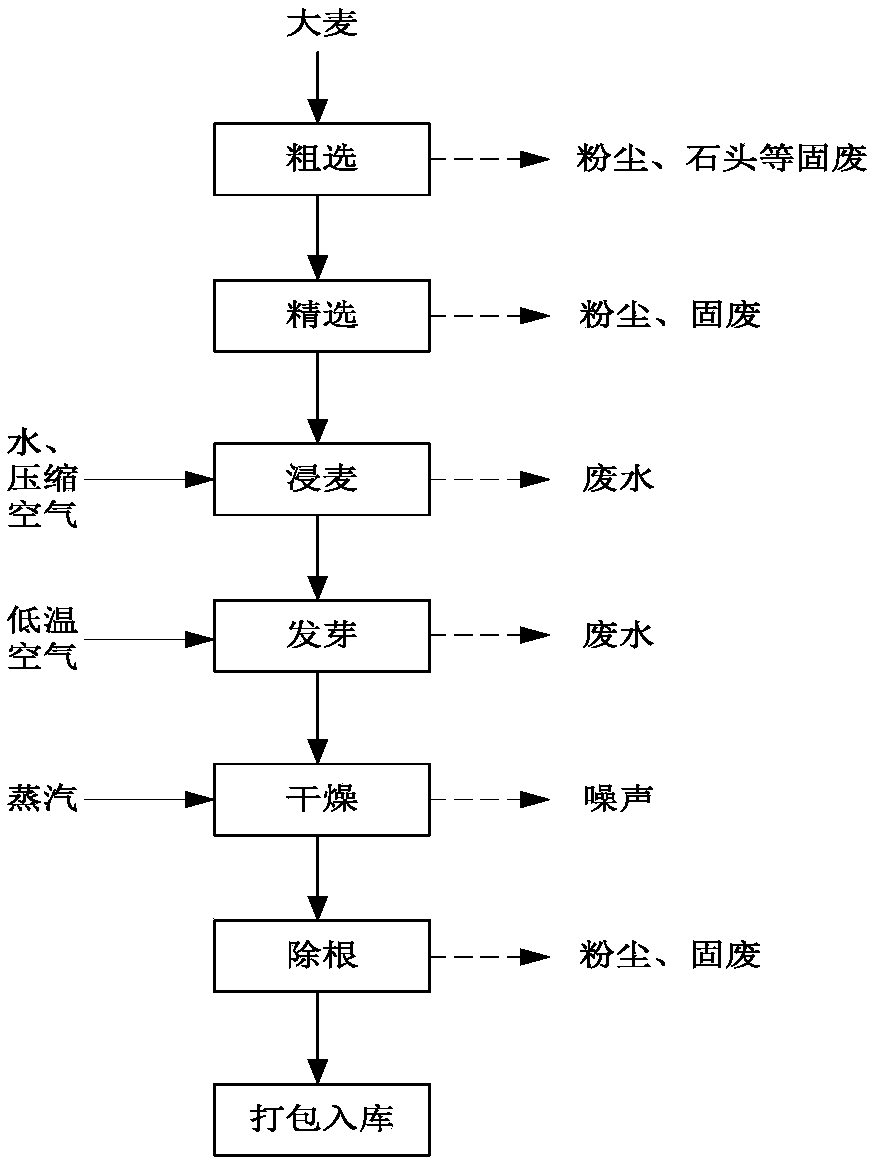

[0027] A malting process for new-flavored pilsner beer, using the Canadian barley variety Metcalfe, and adopting a flat Saladin malt production line; the input volume is 205t; the production process includes malting process, germination process, and drying process;

[0028] Among them, the soaking process includes: the selected barley is transported to the soaking tank through the elevator and buried scraper machine, and then injected with low-temperature water and air to remove impurities such as floating wheat, silt, dust, etc., so that the barley can fully breathe and start to germinate , to produce endogenous gibberellin to act on the aleurone layer to stimulate the activity of the enzyme; to reach the soaking degree required by the process according to the set process curve at the standard time and temperature, and to use 3 soaking processes; the soaking cycle 26 hours, the product temperature is set at 16°C, the rinsing intensity is 100t / h, the dissolved oxygen concentrat...

Embodiment 2

[0034] Preparation technology is with embodiment 1 (see attached figure 1 shown), the difference lies in the selection of Australian barley, variety Bass.

[0035] A flat Saladin malt production line is adopted; the average feeding volume is 205t; the production process includes malting process, germination process, and drying process;

[0036] Among them, the wheat immersion process includes: using 3 wheat immersion processes; the wheat immersion cycle is 26h, the product temperature is set at 16°C, the rinsing intensity is 100t / h, the dissolved oxygen concentration is 8.2-8.6mg / L, and the wheat immersion degree reaches 43.1%. Outcrop rate is 98%.

[0037] The germination process includes: the total germination time is 98 hours, the air temperature of the germination box in the first 3 days is 14°C, the fresh air ratio is set to 30%, the humidity is kept above 95%, and the exhaust air is CO2. 2 The concentration fluctuates from the lowest 1200ppm to the highest 2100ppm; the...

Embodiment 3

[0040] Preparation technology is with embodiment 1 (see attached figure 1 shown), the difference lies in the choice of European two-row spring wheat.

[0041] A flat Saladin malt production line is adopted; the average feeding volume is 205t; the production process includes malting process, germination process, and drying process;

[0042] Among them, the wheat immersion process includes: using 3 wheat immersion processes; the wheat immersion cycle is 26h, the product temperature is set at 16°C, the rinsing intensity is 100t / h, the dissolved oxygen concentration is 8.5-8.8mg / L, and the wheat immersion degree reaches 43.5%. Outcrop rate is 98%.

[0043] The germination process includes: the total germination time is 98 hours, the air temperature of the germination box in the first 3 days is 14°C, the fresh air ratio is set to 30%, the humidity is kept above 95%, and the exhaust air is CO2. 2 The concentration fluctuates from the lowest 1200ppm to the highest 2100ppm; the fres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com