Method for extracting rhodioside in purification fermentation liquid by using macroporous absorbent resin

A technology of salidroside and pore adsorption, which is applied in the field of salidroside, can solve problems such as unreported methods of salidroside, and achieves the effects of environmental friendliness, high yield and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

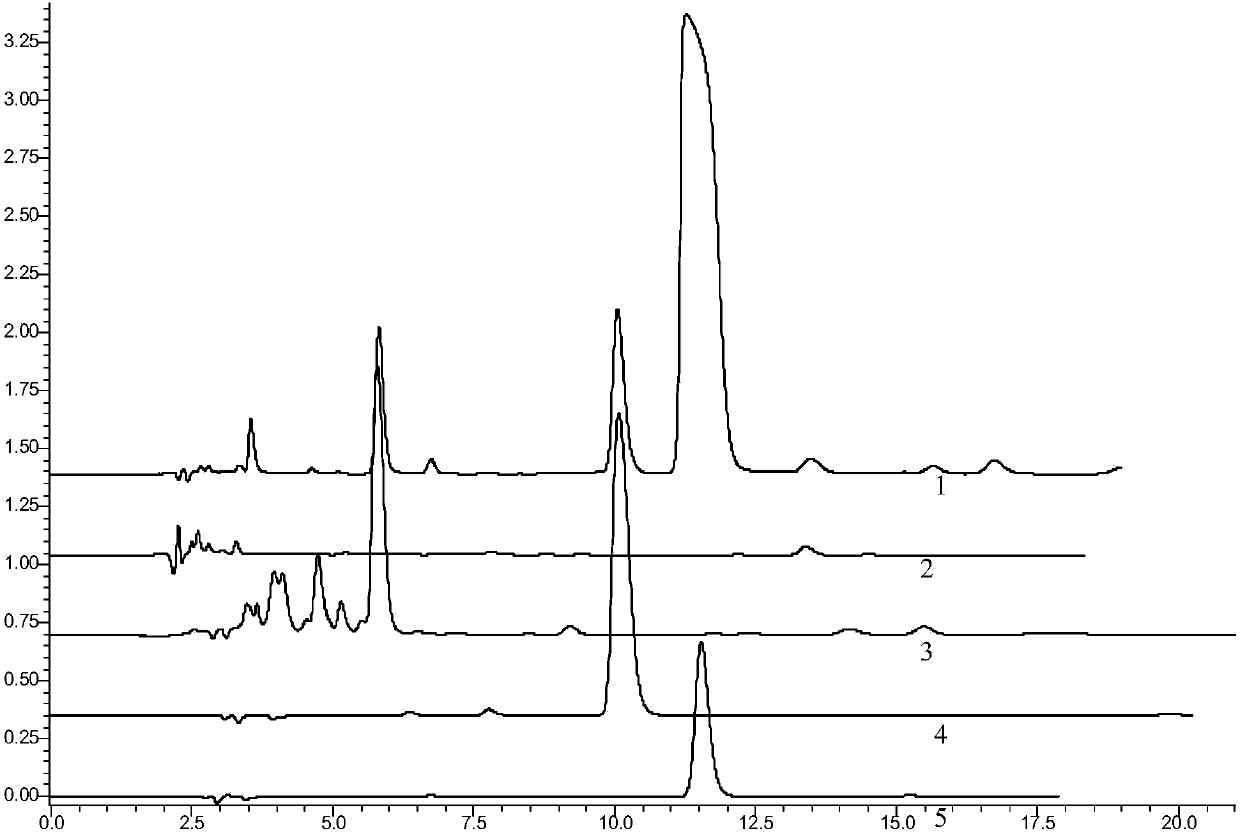

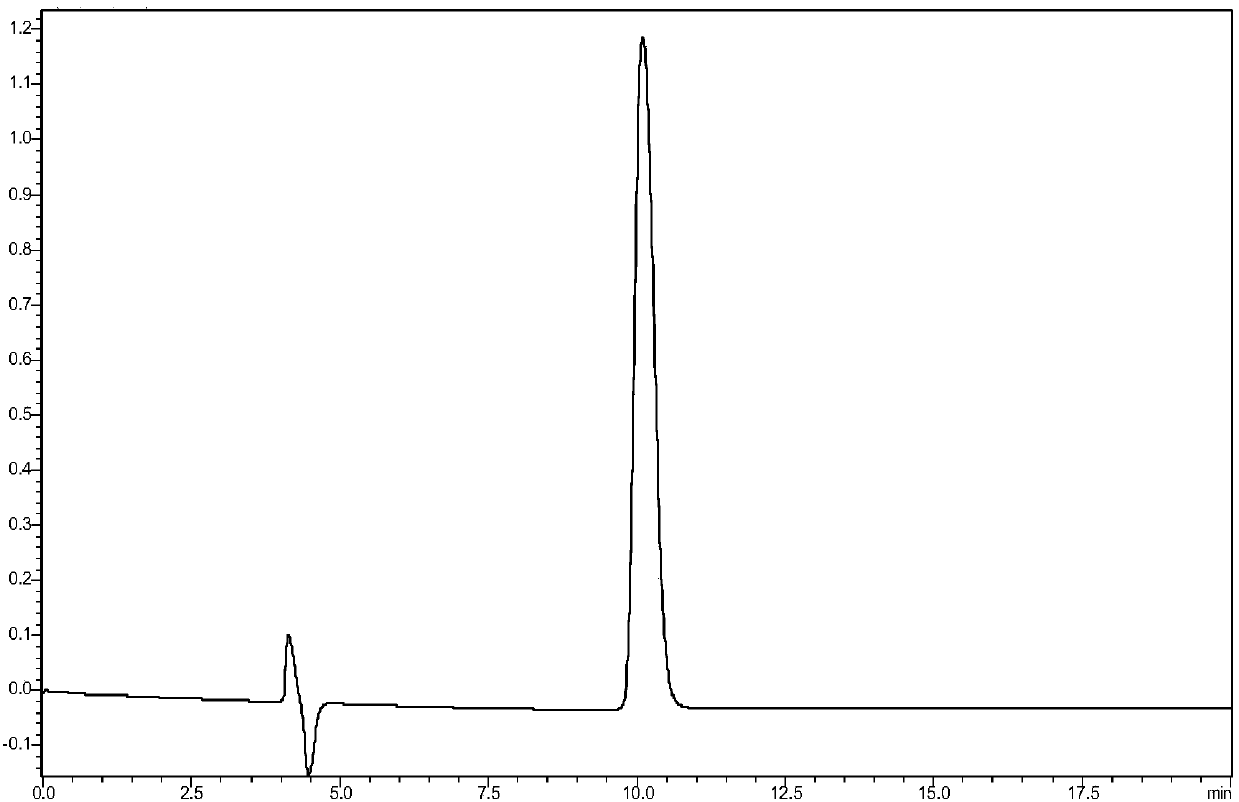

Image

Examples

Embodiment 1

[0038] A method for extracting and purifying salidroside in a fermented liquid using a macroporous adsorption resin, comprising the following steps:

[0039] (1) Centrifuge the Escherichia coli fermentation liquid producing salidroside, and obtain the supernatant as the loading liquid;

[0040] (2) Add 2.5L of the sample solution to the SPB825L macroporous adsorption resin column with the above sample flow rate at 2BV / h;

[0041] (3) Add 1L of water to the macroporous adsorption resin column, elute through the macroporous adsorption resin column with a flow rate of 1BV / h, and remove residual supernatant and polar impurities in the macroporous adsorption resin column;

[0042] (4) With a flow rate of 1BV / h, add 1500mL of ethanol aqueous solution with a volume concentration of 20% to the macroporous adsorption resin column for elution, and collect 300-1200mL of this eluate;

[0043] (5) concentrating the eluate and drying to obtain crude salidroside;

[0044] (6) dissolving the ...

Embodiment 2

[0058] A method for extracting and purifying salidroside in a fermented liquid using a macroporous adsorption resin, comprising the following steps:

[0059] (1) Centrifuge the Escherichia coli fermentation liquid producing salidroside, and obtain the supernatant as the loading liquid;

[0060] (2) Add 1.5L of the sample solution to the AB-8 macroporous adsorption resin column with the above sample flow rate as 1BV / h;

[0061] (3) Add 1L of water to the macroporous adsorption resin column, and elute through the macroporous adsorption resin column with a flow rate of 0.5BV / h to remove residual supernatant and polar impurities in the macroporous adsorption resin column;

[0062] (4) With a flow rate of 0.5BV / h, add 2000mL of ethanol solution with a volume concentration of 10% to the macroporous adsorption resin column for elution, and collect 500-1600mL of this eluate;

[0063] (5) concentrating the eluate and drying to obtain crude salidroside;

[0064] (6) dissolving the cru...

Embodiment 3

[0067] A method for extracting and purifying salidroside in a fermented liquid using a macroporous adsorption resin, comprising the following steps:

[0068] (1) Centrifuge the Escherichia coli fermentation liquid producing salidroside, and obtain the supernatant as the loading liquid;

[0069] (2) Add 2L of the sample solution into the HPD-100C macroporous adsorption resin column at a flow rate of 3BV / h;

[0070] (3) Add 1L of water to the macroporous adsorption resin column, elute through the macroporous adsorption resin column with a flow rate of 2BV / h, and remove residual supernatant and polar impurities in the macroporous adsorption resin column;

[0071] (4) With a flow rate of 2BV / h, add 2000mL of ethanol solution with a volume concentration of 15% to the macroporous adsorption resin column for elution, and collect 400-1300mL of this eluate;

[0072] (5) concentrating the eluate and drying to obtain crude salidroside;

[0073] (6) dissolving the crude salidroside in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com