Glue injection machine

A technology of glue injection machine and glue injection mold, which is applied in the field of glue injection machine, can solve problems such as cable scrapping, damage to precision instruments and equipment, loss, etc., and achieve the effects of reliable use, improved work efficiency, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

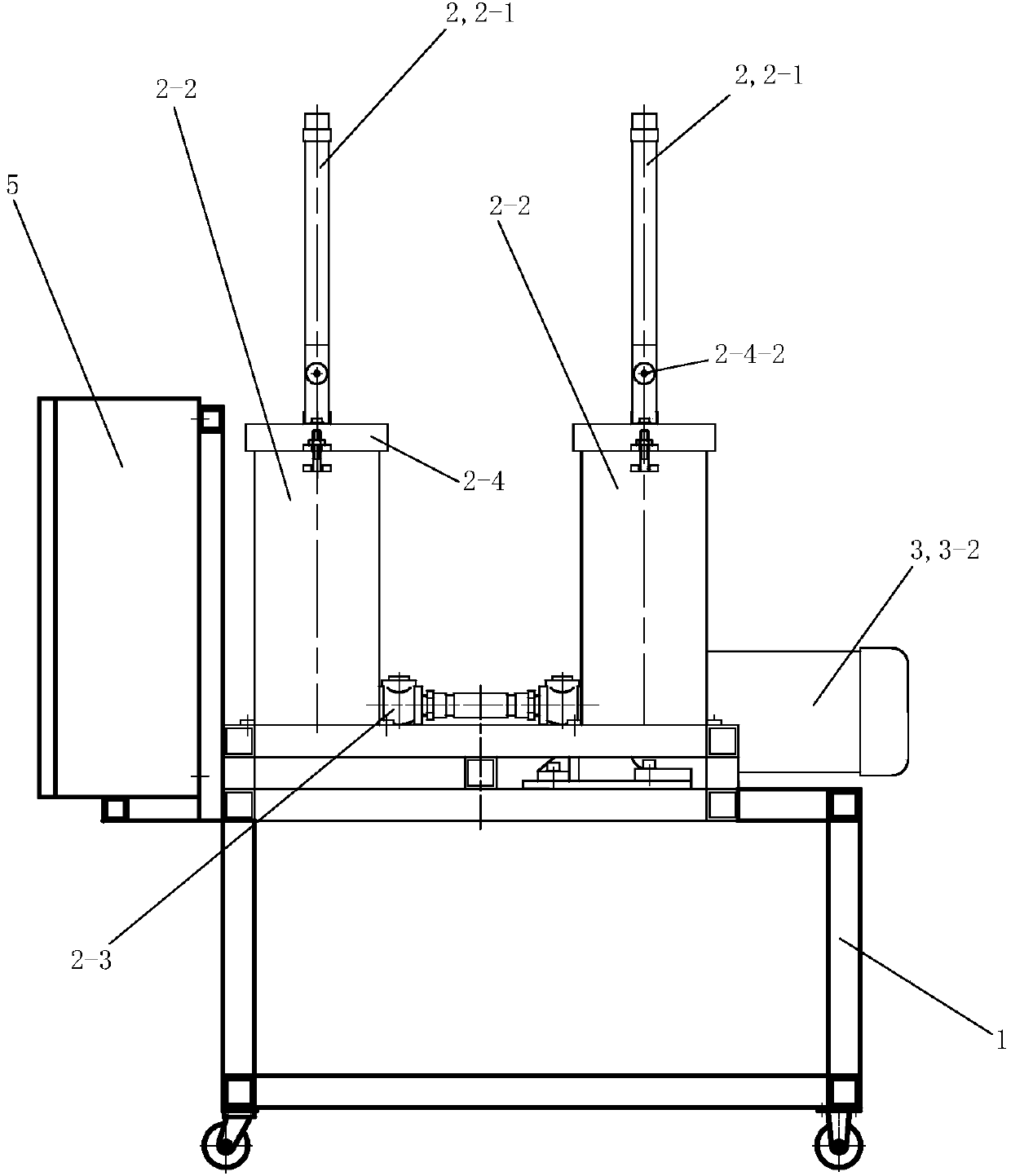

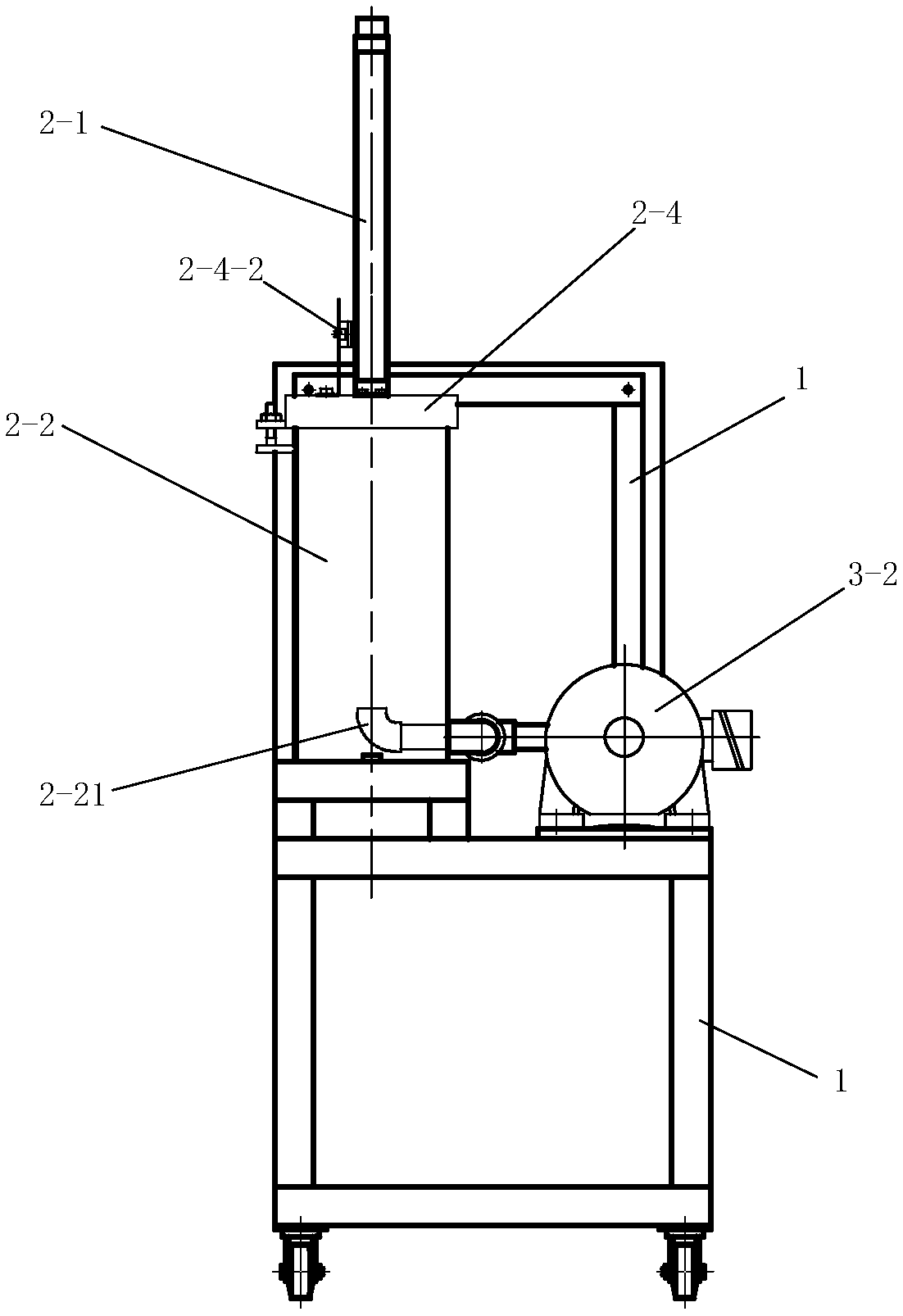

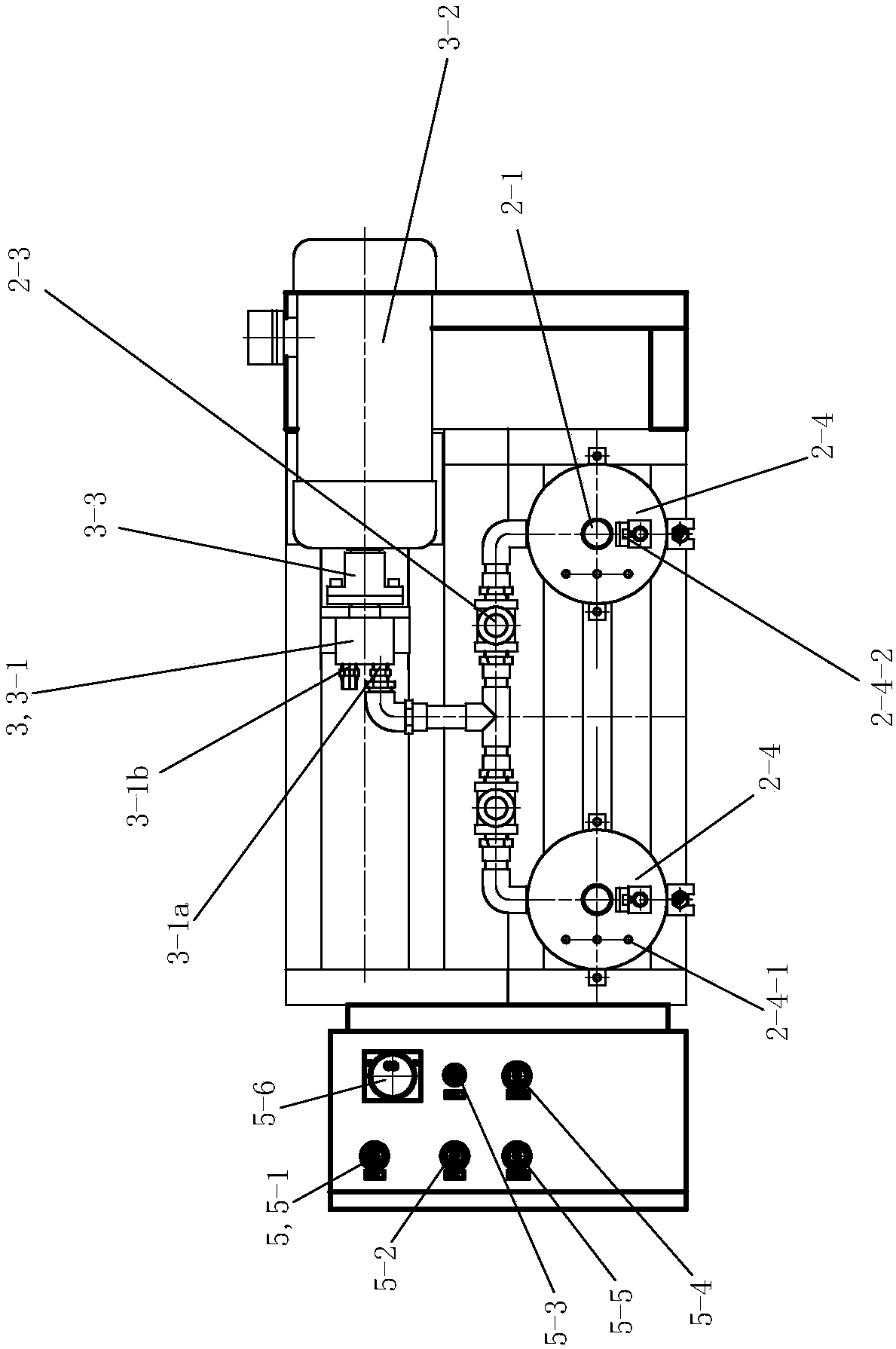

[0035] The description of the glue injection machine of the present embodiment follows figure 1 in the orientation shown, i.e. figure 1 The up, down, left, and right directions shown are the described up, down, left, and right directions. figure 1 The side facing is the front, and the side facing away from figure 1 One of the sides is the rear, and the orientation of the injection mold assembly is described in the photo Image 6 in the orientation shown, i.e. Image 6 The up, down, left, and right directions shown are the described up, down, left, and right directions. Image 6 The side facing is the front, and the side facing away from Image 6 One side is the rear.

[0036] See Figure 1 to Figure 12 , The glue injection machine of the present invention includes a frame 1 , a glue feeding assembly 2 , a flow regulating assembly 3 , a glue injection mold assembly 4 and a control device 5 . The lower part of the frame 1 is provided with casters, which is convenient for ...

Embodiment 2)

[0041] The description of the glue injection machine of the present embodiment follows figure 1 in the orientation shown, i.e. figure 1 The up, down, left, and right directions shown are the described up, down, left, and right directions. figure 1 The side facing is the front, and the side facing away from figure 1 One of the sides is the rear, and the orientation of the injection mold assembly is described in the photo Figure 7 in the orientation shown, i.e. Figure 7 The up, down, left, and right directions shown are the described up, down, left, and right directions. Figure 7 The side facing is the front, and the side facing away from Figure 7 One side is the rear.

[0042] See Figure 7 to Figure 12 , The rest of this embodiment is the same as that of Embodiment 1, except that the injection mold assembly 4 also includes a liner 4-2, a deep groove ball bearing 4-3 and a pressure ring 4-4.

[0043] See Figure 7 to Figure 12 , Die cover 4-1 is a steel integral pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com