Multi-station resistance detection device

A resistance detection, multi-station technology, applied in measuring devices, measuring resistance/reactance/impedance, measuring electricity, etc., to achieve the effect of saving production space, reducing labor intensity, and reducing operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

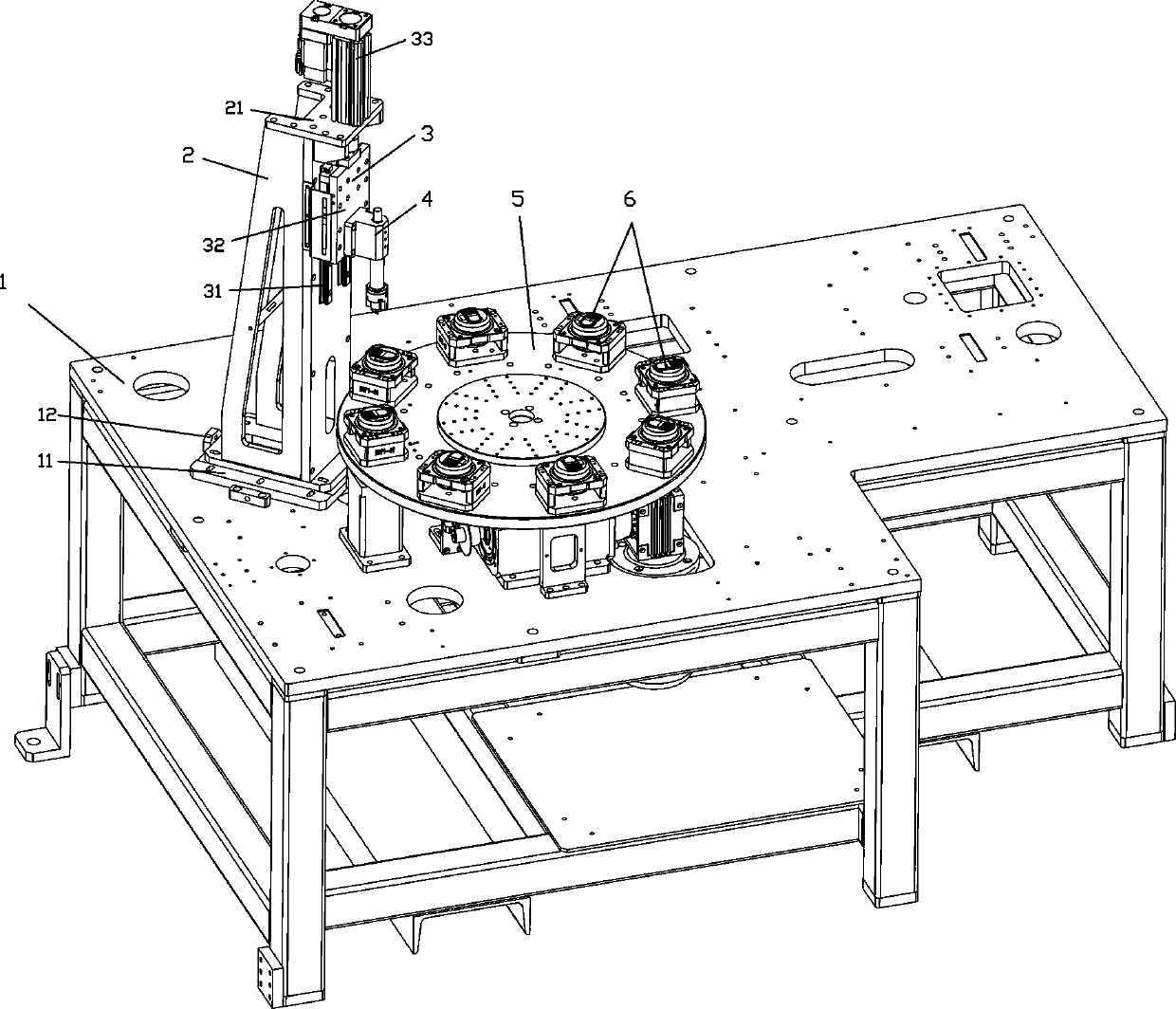

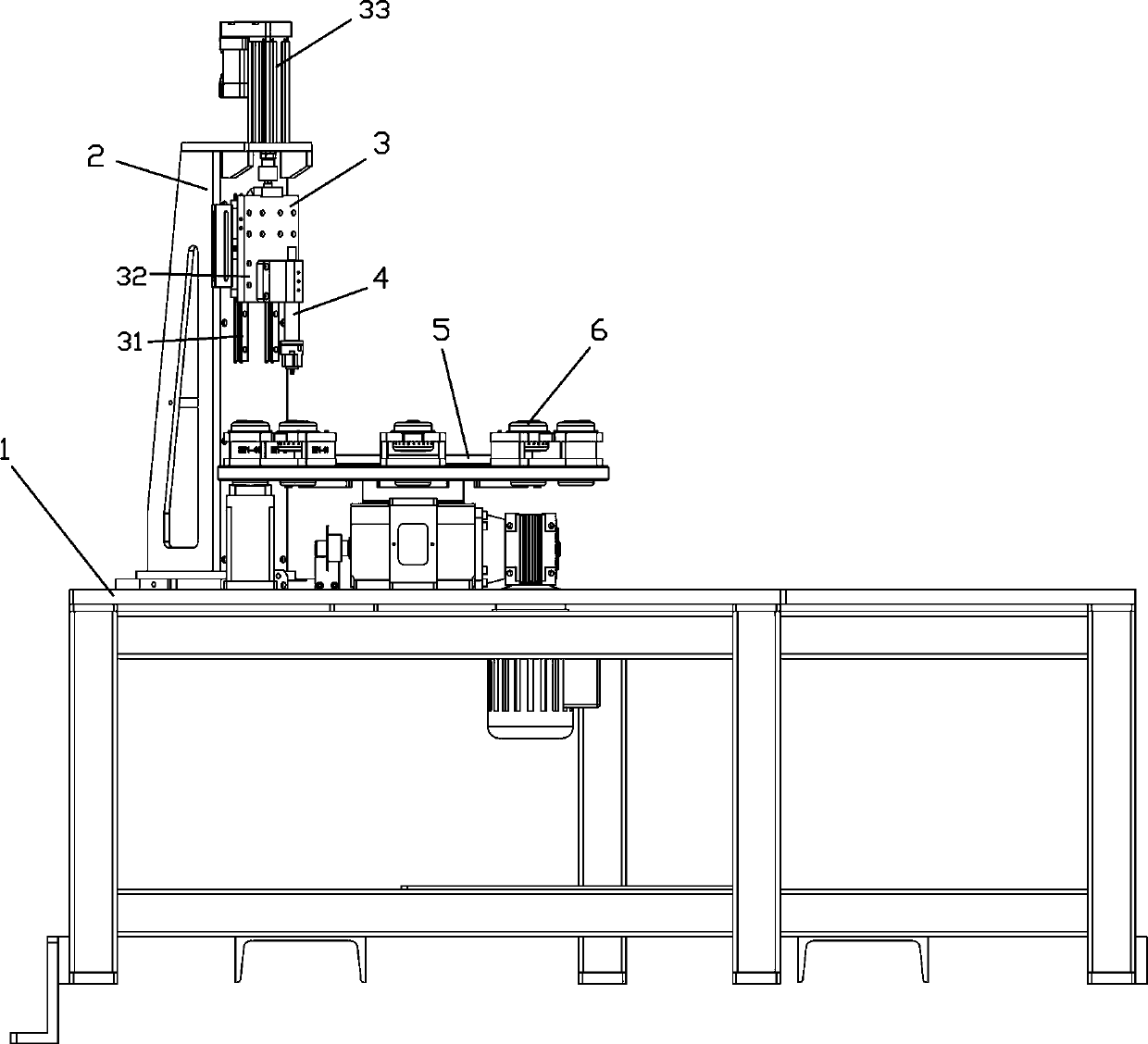

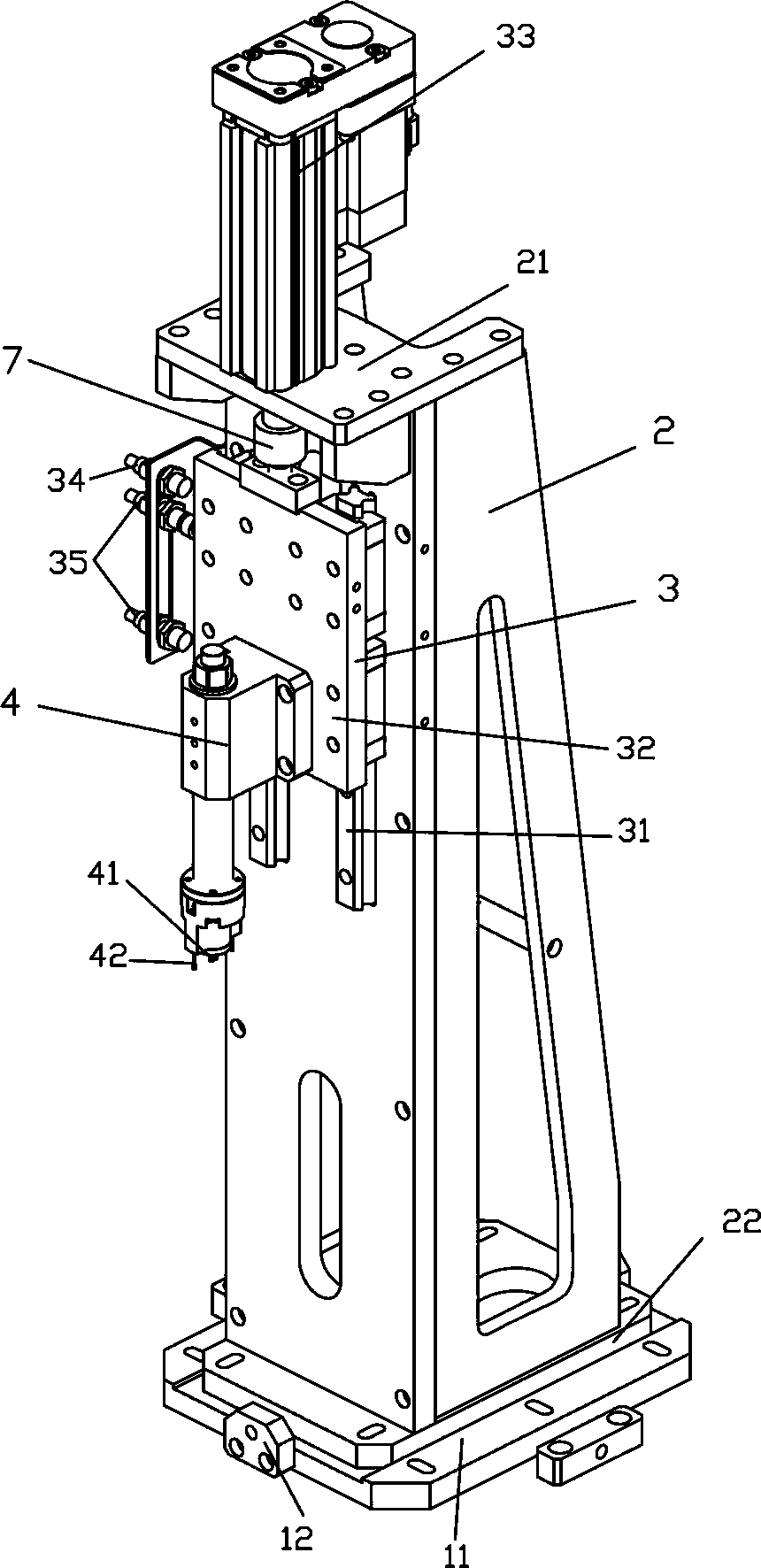

[0026] see Figure 1 to Figure 8 , a multi-station resistance detection device of the present invention, which includes,

[0027] bottom plate 1;

[0028] The fixed bracket 2 is a frame structure, which is vertically arranged on the bottom plate 1, and a fixed plate 21 is horizontally arranged on the top;

[0029] Lifting mechanism 3, comprising,

[0030] Two linear guide rails 31 and their upper slide 32 are arranged on one side of the fixed bracket 2 along the height direction of the fixed bracket 2;

[0031] Servo electric cylinder 33, its cylinder body is arranged on the upper end surface of the fixed plate 21 of the fixed bracket 2, and its piston rod passes through the fixed plate 21 to connect to the slide table 32;

[0032] The electric cylinder origin sensor switch 34 and the protection sensor switch 35 are arranged on the fixed bracket 2 on one side of the slide table 32 through a bracket, and are arranged axially along the linear guide rail 31;

[0033] The dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com