Self-resetting deformation compatibility floor slab joint structure

A node structure and self-resetting technology, which is applied to building components, building structures, earthquake resistance, etc., can solve problems such as screw thread breakage, achieve the effect of reducing repair work and clear and reasonable force mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

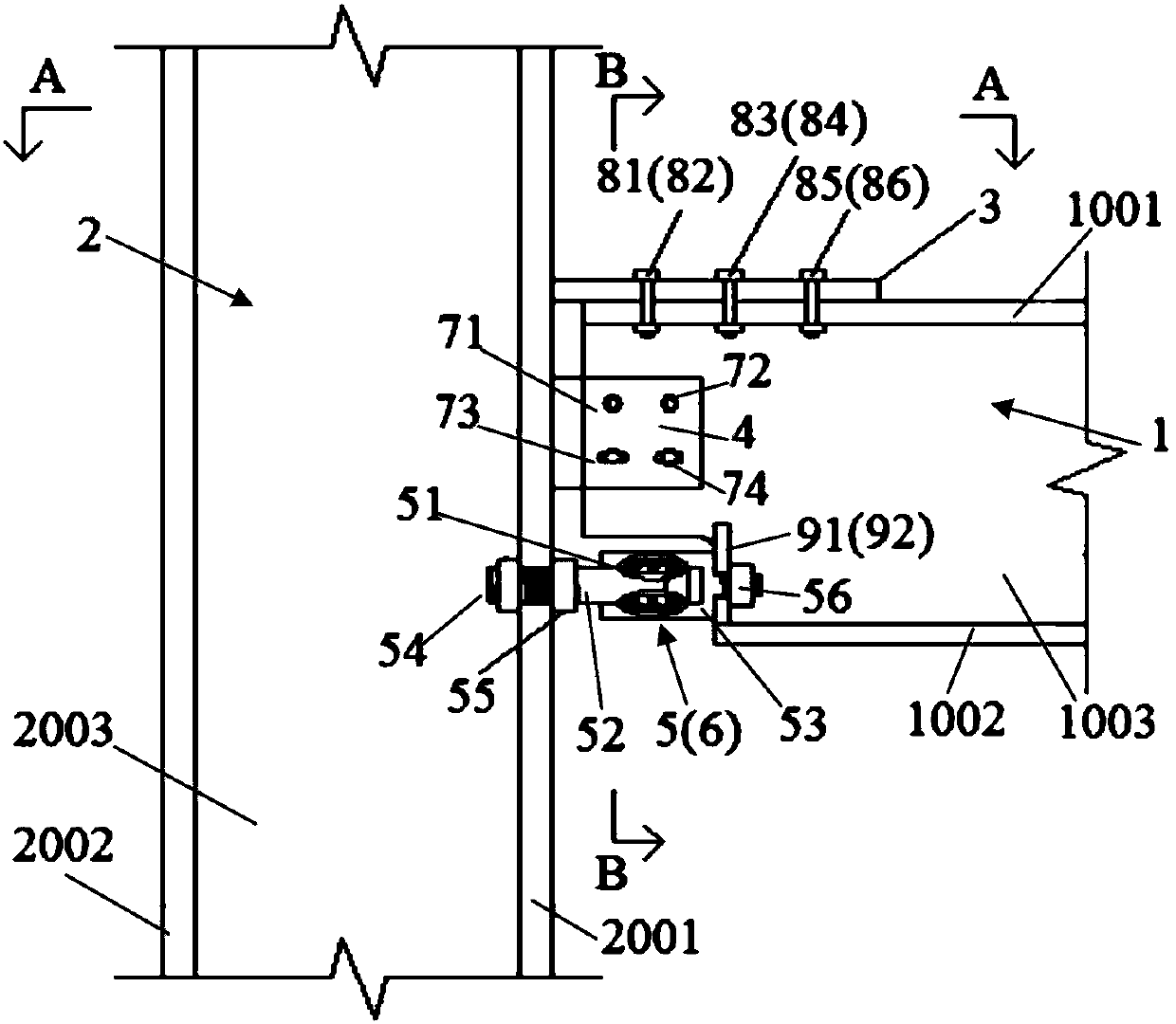

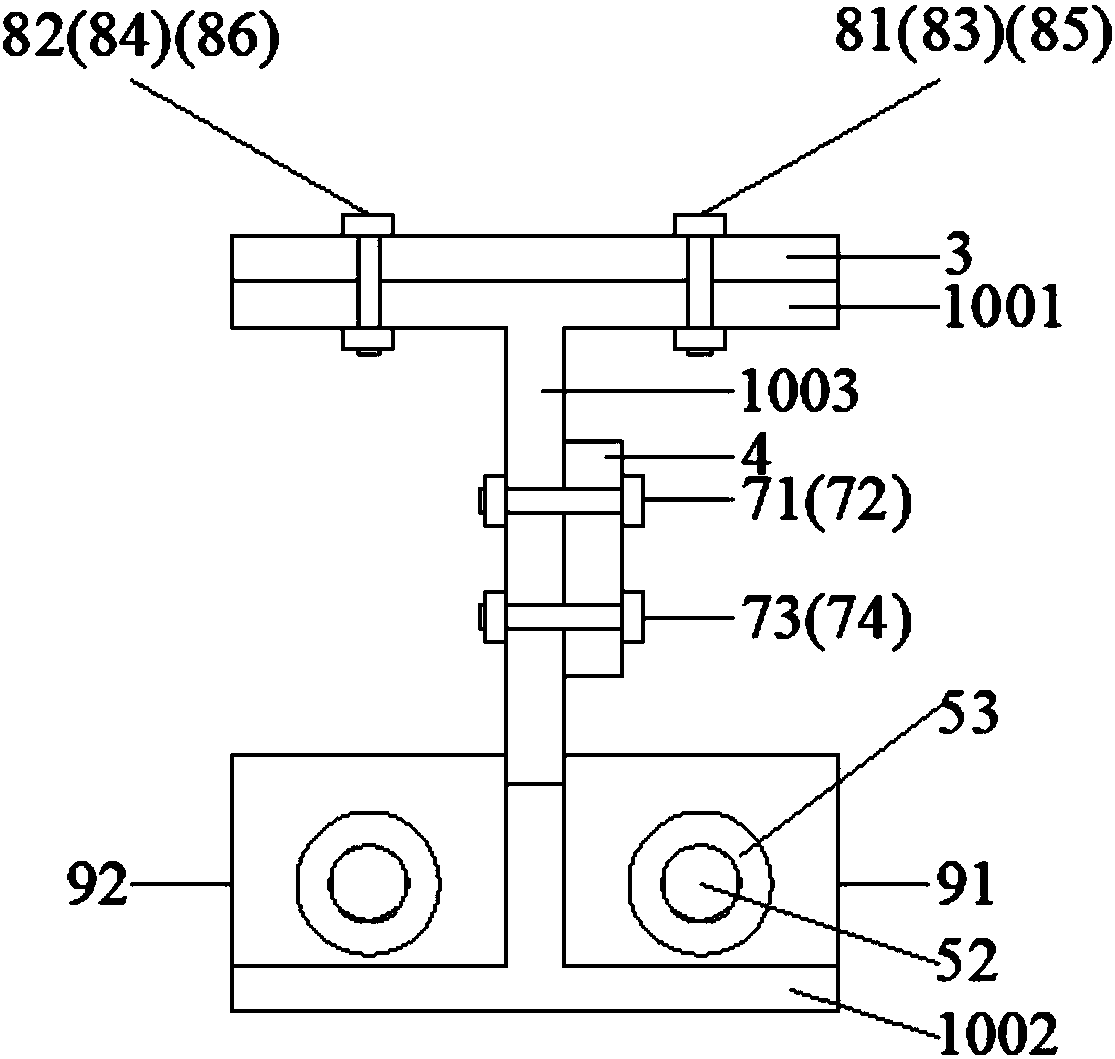

[0031] Such as figure 1 As shown, the present invention firstly provides a self-resetting deformation-coordinated floor node structure, including I-shaped notch steel beams 1, I-shaped steel columns 2, and special node domains for connecting I-shaped steel beams and columns. The special node domain includes upper cover plate 3, shear plate 4, cover plate bolts 81\82\83\84\85\86, web bolts 71\72\73\74, first self-resetting core device 5 and second Self-resetting core device 6 . During installation, the shear plate 4 is first welded to the front flange 2001 of the I-shaped steel column, and then connected to the web 1003 of the I-shaped notch steel beam through the web bolts 71\72\73\74.

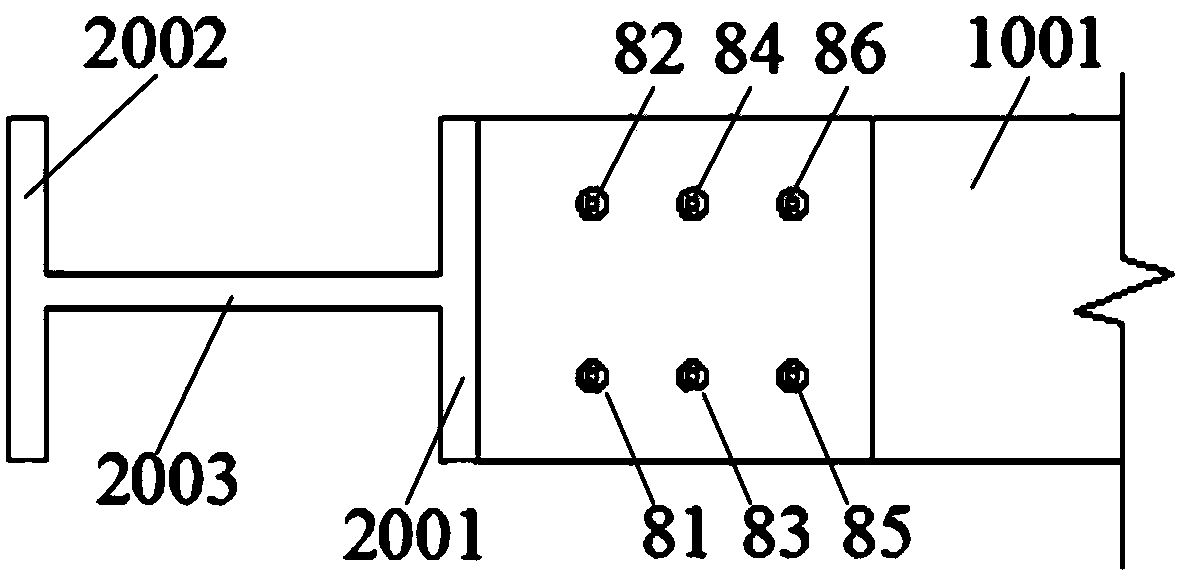

[0032] Subsequently, if figure 2 As shown in the sectional view of the node along line A-A, one end of the upper cover plate 3 is welded to the front flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com