Manual hole digging pile assembly type protection wall and construction technology thereof

A manual digging pile and assembly technology, applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of unable to form support system in time and effectively, reduce engineering cost, speed up engineering progress, etc., and achieve life safety Guaranteed, reliable hole-forming quality, and environmentally friendly construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

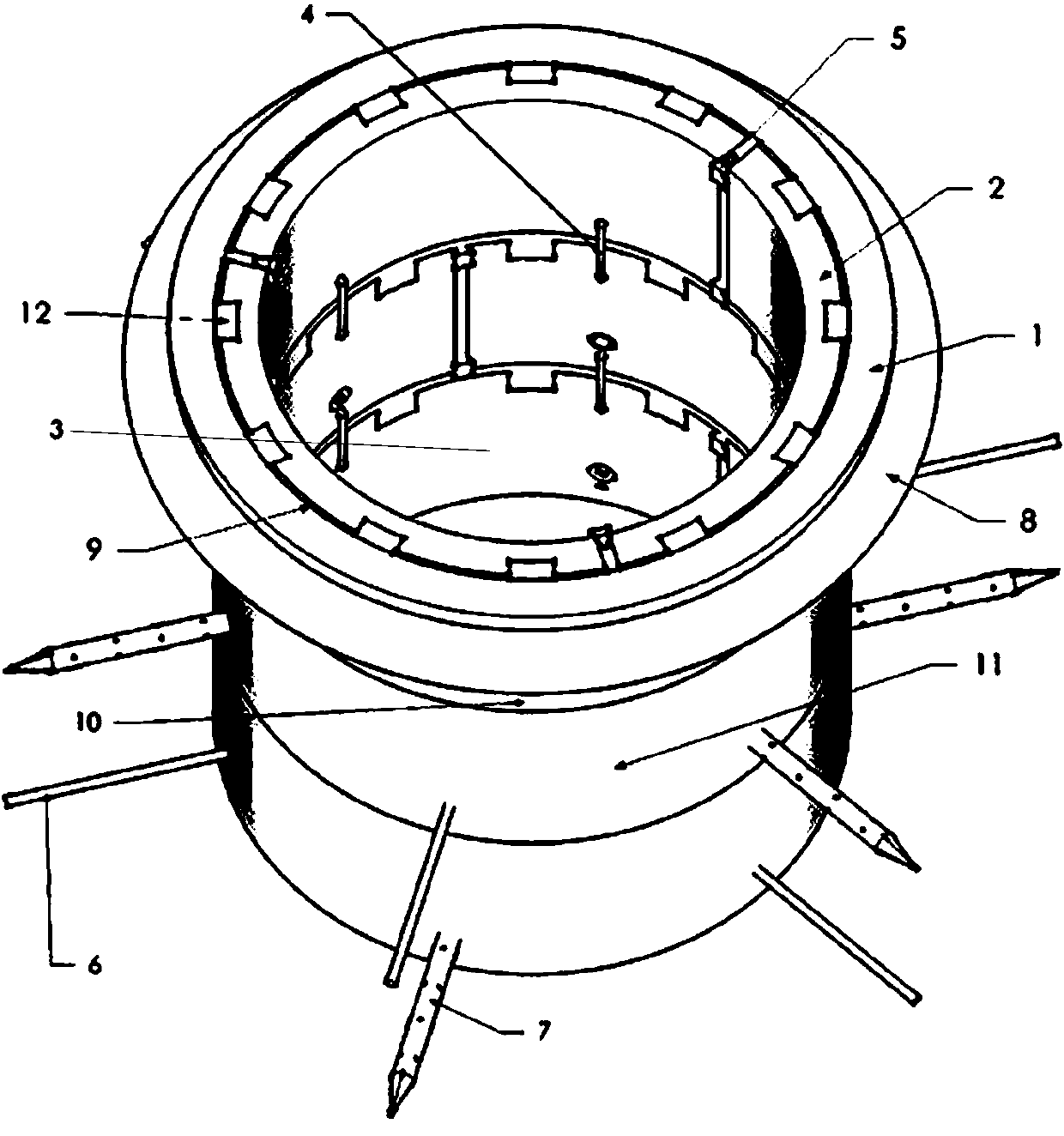

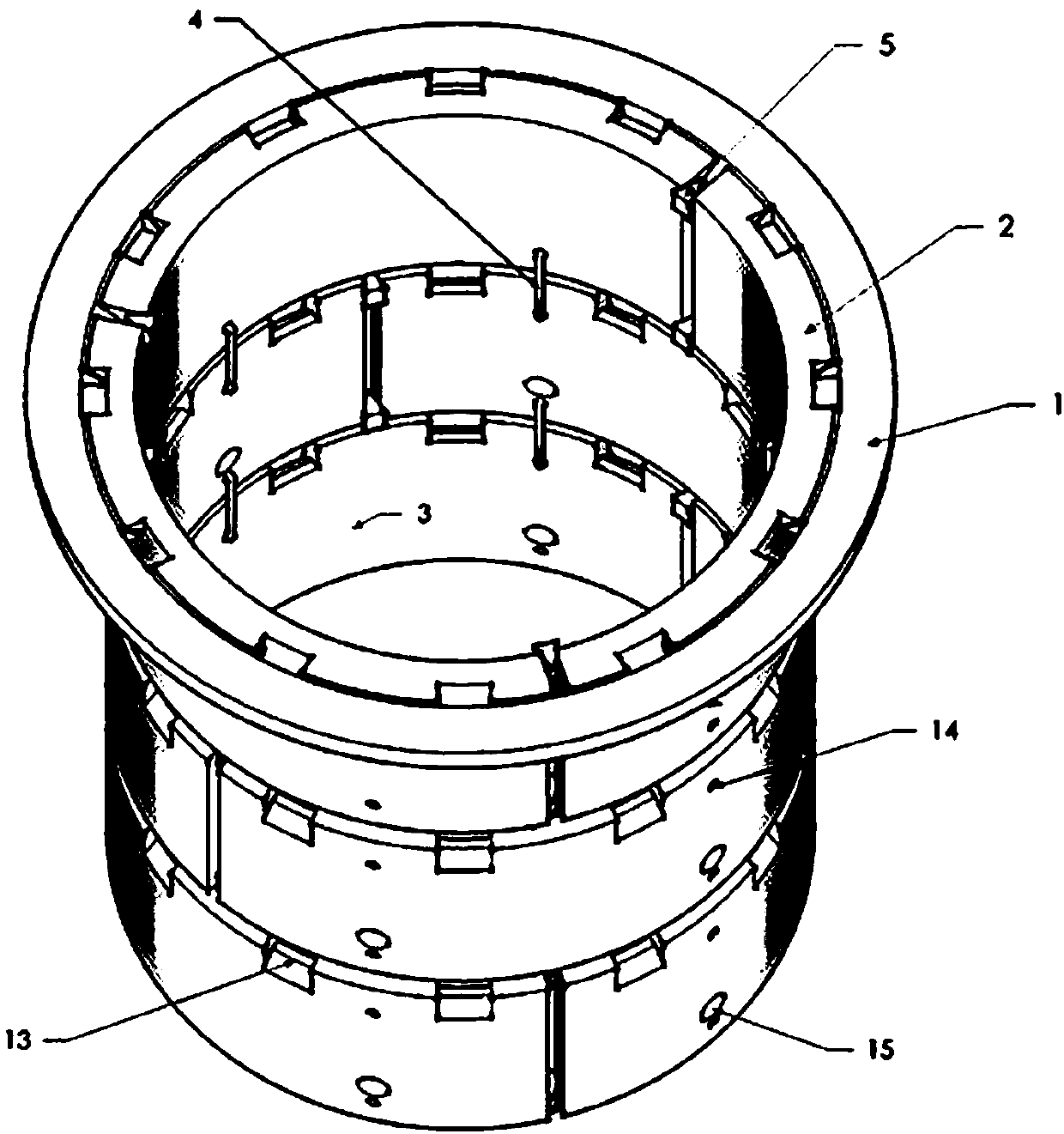

[0024] In the following, with reference to the accompanying drawings and preferred embodiments, the specific implementation, structure, features, and effects of a manual digging pile assembly-type protective wall and its construction process according to the present invention are described in detail as follows.

[0025] See Figure 1-3 , A manual digging pile assembly type wall protection, which is characterized in that it is composed of prefabricated components, auxiliary parts and cast-in-place concrete. The prefabricated components include well circle 1, well head 2 and standard section 3. The inner side of well circle 1 is a rounded platform Wellhead 1 and wellhead 2 are connected, wellhead 2 is spliced by three arc-shaped plates, and the upper part of wellhead 2 is provided with multiple evenly distributed pouring ports A12; standard section 3 is spliced by three arc-shaped plates, and the upper part of standard section 3 is uniform There are multiple pouring ports B13; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com