Cool knitted fabric

A knitted fabric, a cool technology, applied in the field of textile fabrics, can solve problems such as stuffy heat and discomfort, and achieve the effects of improving the cold feeling on contact, speeding up the export speed, and good hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

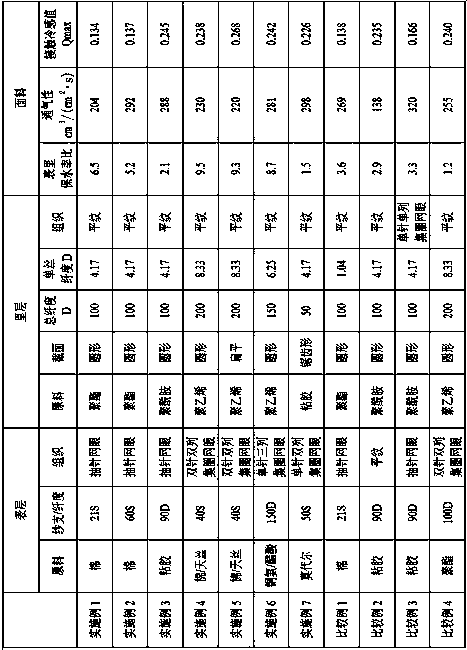

Embodiment 1

[0033] On the 20G double-sided circular knitting machine, 21S cotton spun yarn (undyed) is used as the surface yarn, and 100D / 24f polyester coarse denier filament (single filament size 4.17D) with a circular cross section is used as the inner yarn. The surface layer is made of needle mesh and the inner layer is woven with plain weave to obtain a knitted gray fabric. After scouring, washing, finishing (soft resin processing) and other processing, the grammage is 162g / m 2 knitted fabric.

[0034] The surface-to-surface water retention ratio of the obtained fabric is 6.5, the Qmax value of contact cold feeling is 0.134, and the air permeability is 204㎝ 3 / (㎝ 2 ・s). See Table 1.

Embodiment 2

[0036]On the 20G double-sided circular knitting machine, 60S cotton spun yarn (undyed) is used as the surface yarn, and 100D / 24f polyester coarse denier filament (single filament size: 4.17D) with a circular cross section is used as the inner yarn. The surface layer is made of needle mesh and the inner layer is woven with plain weave to obtain a knitted gray fabric. After scouring, washing, finishing (soft resin processing) and other processing, the grammage is 125g / m 2 knitted fabric.

[0037] The surface-to-surface water retention ratio of the obtained fabric is 5.2, the Qmax value of contact cold feeling is 0.137, and the air permeability is 292㎝ 3 / (㎝ 2 ・s). See Table 1.

Embodiment 3

[0039] On a 22G double-sided circular knitting machine, 90D / 48f viscose filament (undyed) is used as the surface yarn, and 100D / 24f cool polyamide coarse denier filament with a circular cross-section (single filament fineness 4.17D, spinning process added natural cool minerals) as the inner layer yarn, the surface layer is a needle mesh, and the inner layer is a plain weave weave to obtain a knitted gray fabric, and then after scouring, dyeing, washing, finishing (soft resin processing) and other processing , to obtain a gram weight of 128g / m 2 knitted fabric.

[0040] The surface-to-surface water retention ratio of the obtained fabric is 2.1, the Qmax value of contact cold feeling is 0.245, and the air permeability is 288㎝ 3 / (㎝ 2 ・s). See Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com