A sliding device and its working method

A technology of sliding device and working method, which is applied in the direction of transportation and packaging, special-purpose ships, warships, etc., and can solve the problems of increasing the construction cost of marine engineering equipment, potential safety hazards of marine engineering equipment strength, increasing the difficulty and cost of marine engineering equipment, etc. , to achieve the effect of avoiding repeated design and repeated construction, reducing construction costs and enhancing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following references are attached figure 1 to the attached Figure 8 , each embodiment of the present invention will be further elaborated.

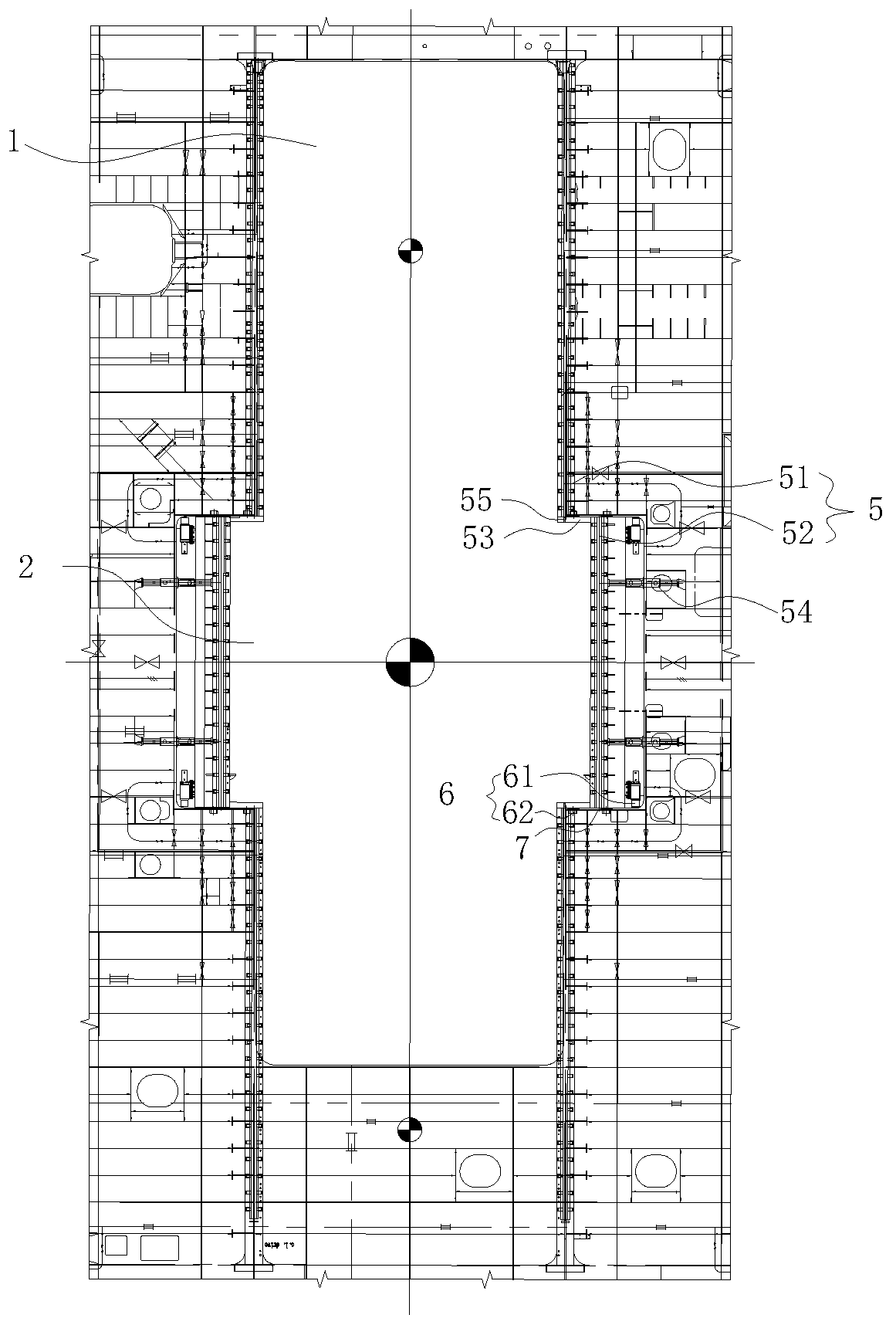

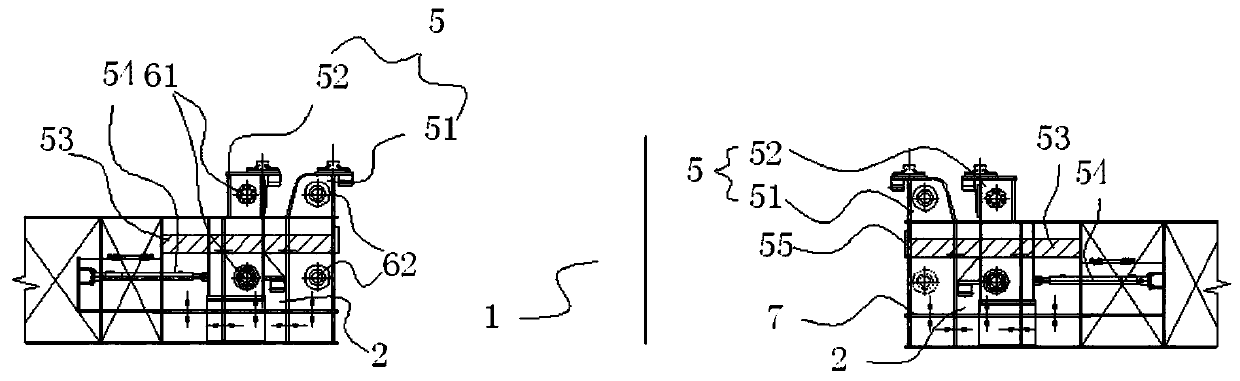

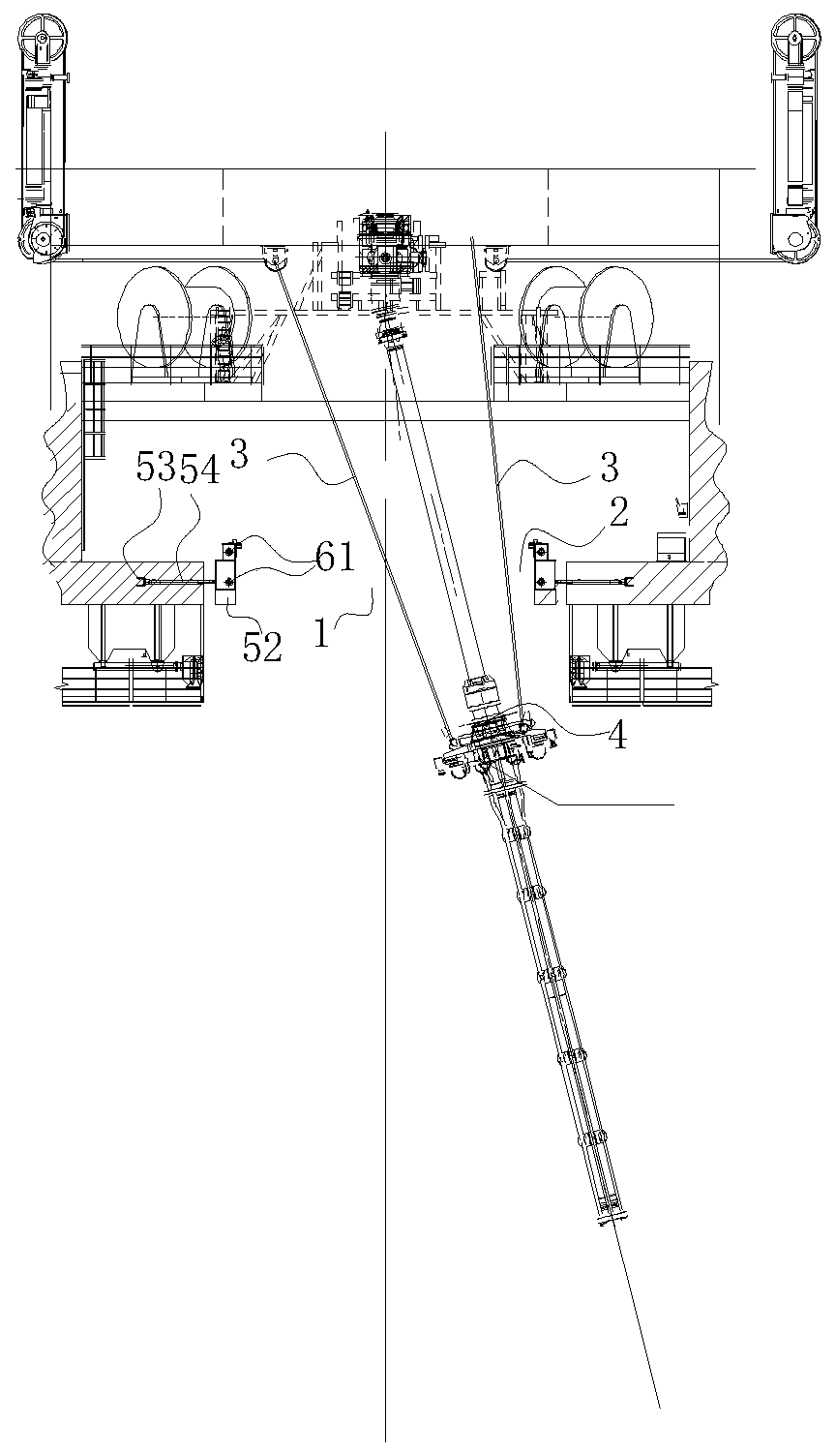

[0036] as attached figure 1 , attached Figure 5 As shown, one aspect of the present invention provides a sliding device 5 for moving devices such as a blowout preventer lift and a suspension trolley on offshore equipment, and the sliding device 5 is arranged on both sides of the moon pool; the moon pool includes The first space 1 and the second space 2 arranged on both sides of the length direction of the first space 1; the sliding device 5 includes: two fixed slide rails 51 and two fixed slide rails 51 respectively fixed on both sides of the length direction of the first space 1 The movable slide rails 52 are respectively arranged on both sides in the length direction of the second space 2 , the fixed slide rails 51 are disconnected in the second space 2 , and the movable slide rails 52 can be moved to the second space 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com