Torque-convertible automatic stirring device

A technology of automatic stirring and stirring devices, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., which can solve the problems of high viscosity, high labor cost and complex structure of viscous materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention will be further described below in conjunction with the accompanying drawings.

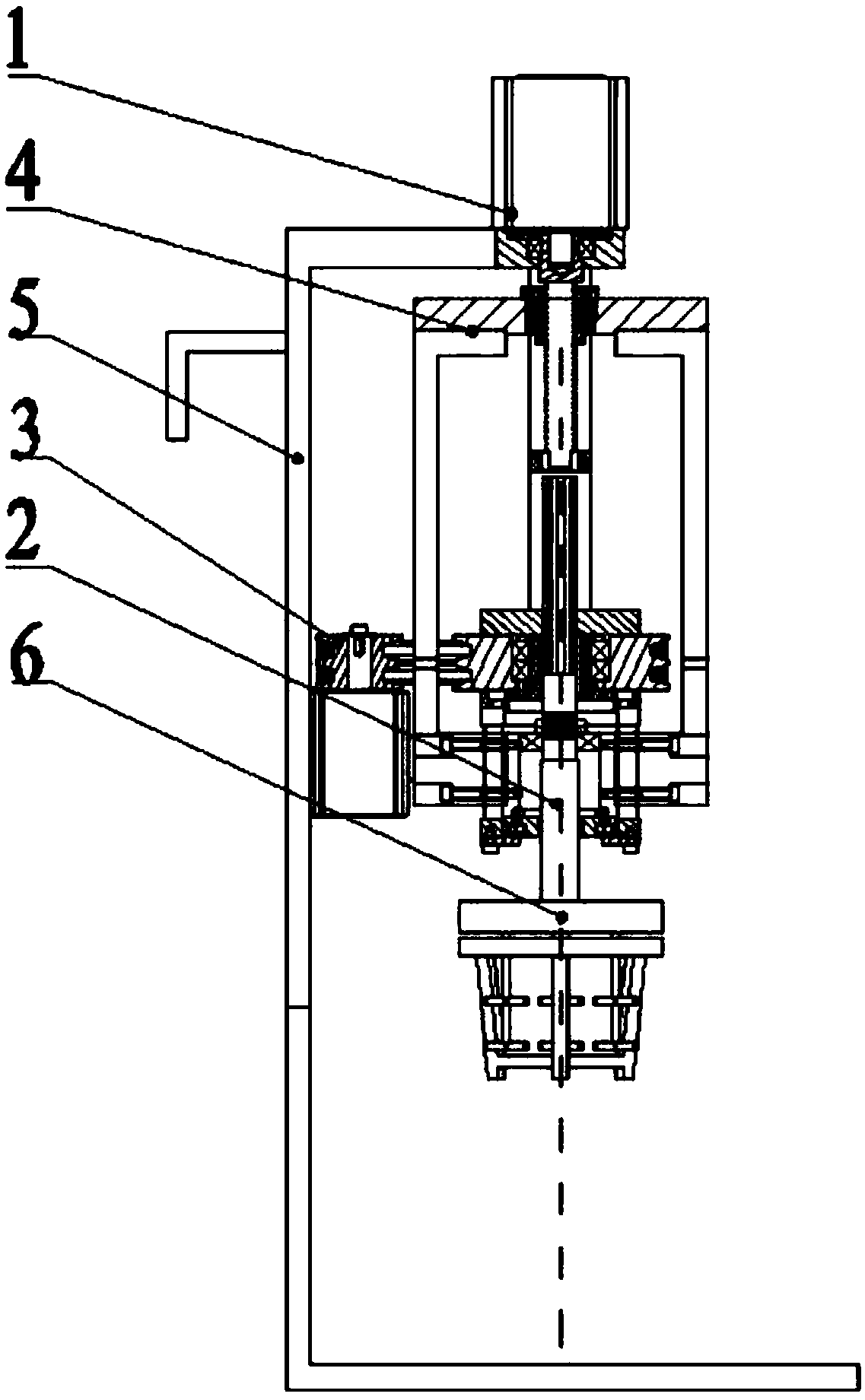

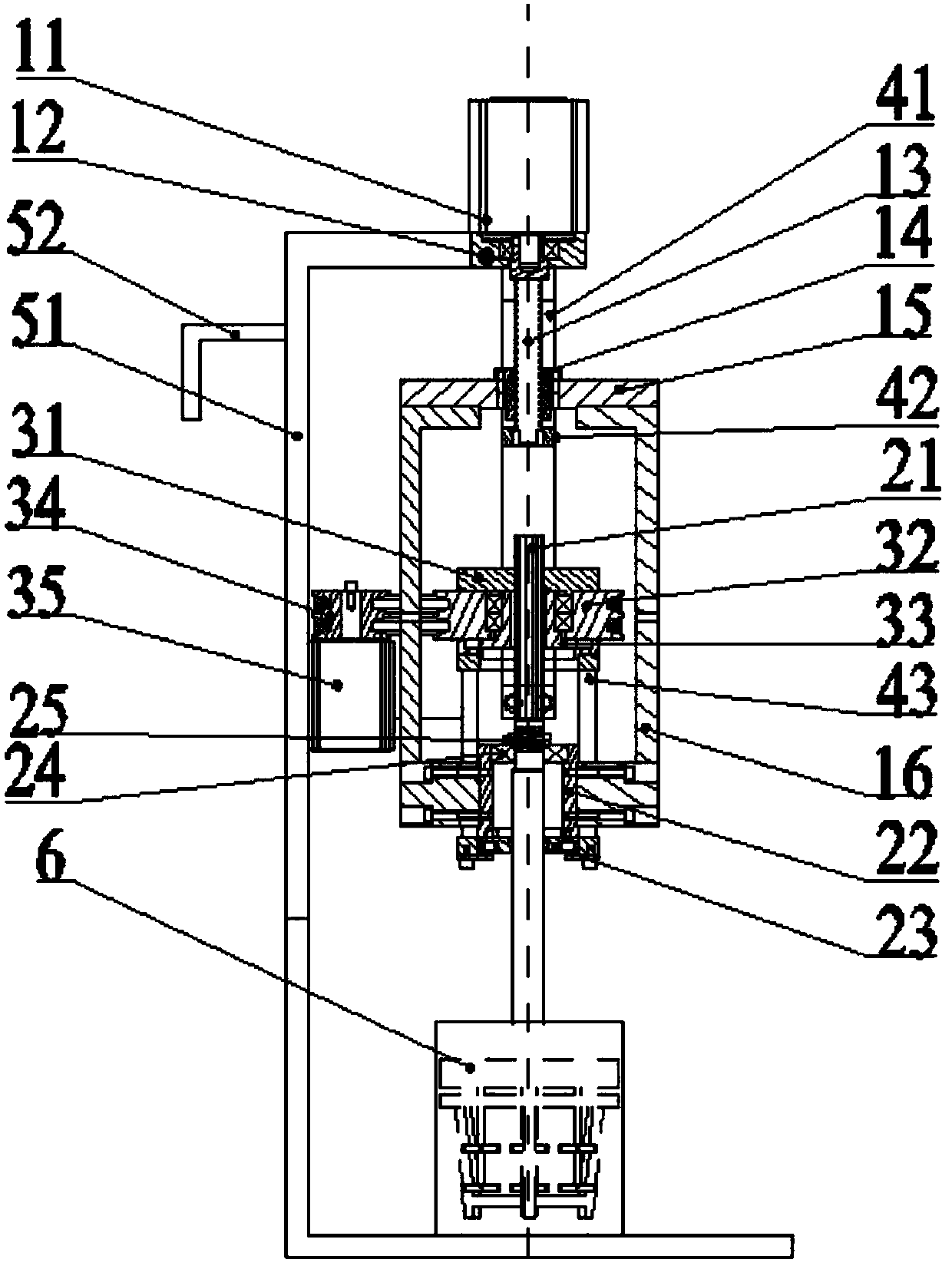

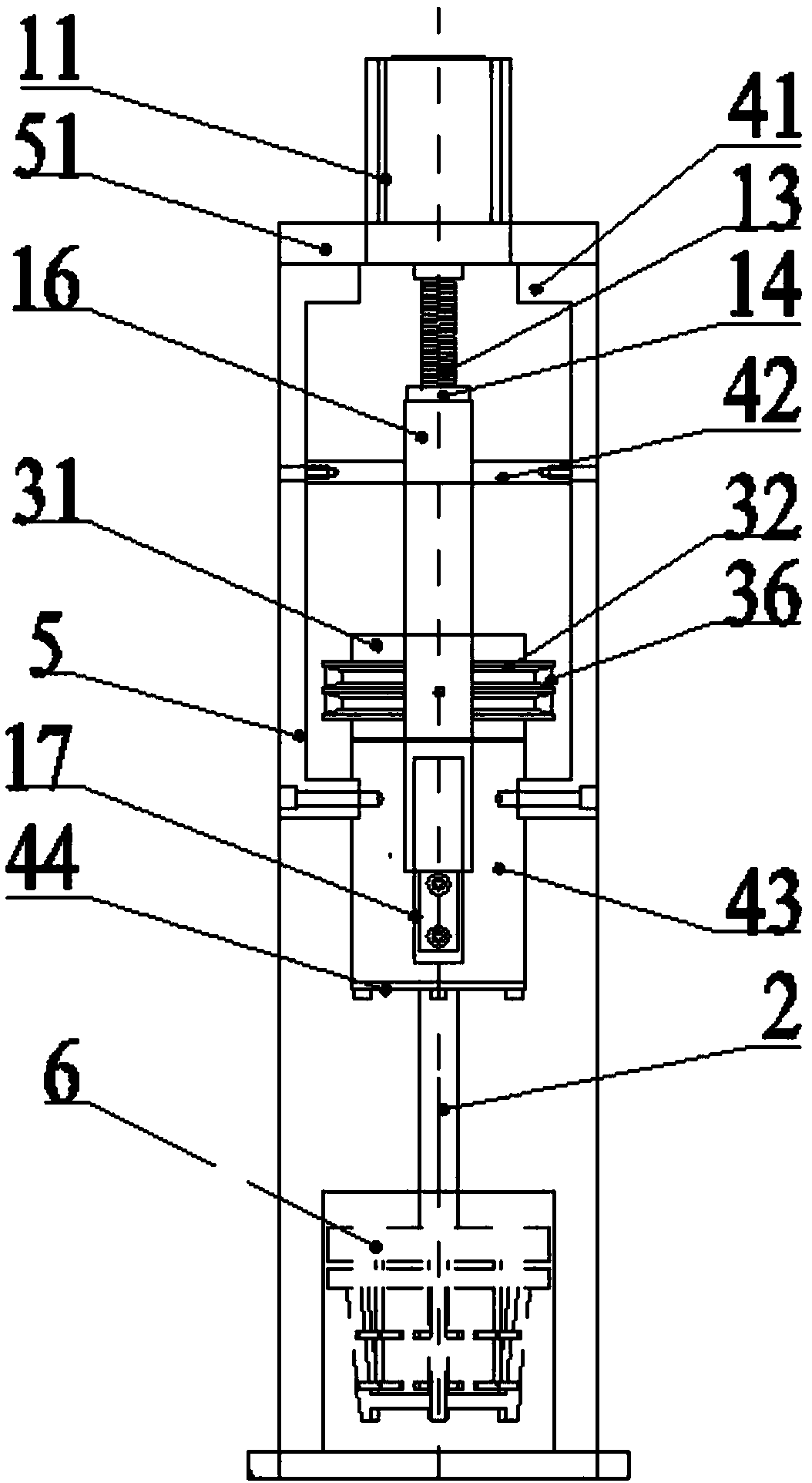

[0021] Such as figure 1 , 2 , 3, 4, and 5, a torque-convertible automatic stirring device includes a lifting device 1, a rotating shaft system 2, a rotating device 3, a rotating shaft supporting device 4, a frame system 5, and a planetary wheel stirring device 6; The vertical motor of device 1 is installed on the frame system 4, the shaft system 2 is connected with the rotation device 3 through a spline, the shaft system 2 is connected with the shaft support device 4, and the shaft support device 4 is connected with the lifting device 1, the rotating device 3 is fixed on the side wall of the frame system 5, and the planetary wheel stirring device 6 is connected with the shaft system 2; the lifting device 1 includes: a vertical Motor 11, vertical motor mounting plate 12, ball screw 13, nut 14, nut mounting plate 15, L-shaped movable frame 16, connecting plate 17; the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com