Adhesive tape pasting device for fishing rod adhesive tape winding machine

A technology for sticking tape and winding machine, which is applied in the directions of transportation and packaging, sending objects, and thin material processing. Product quality, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

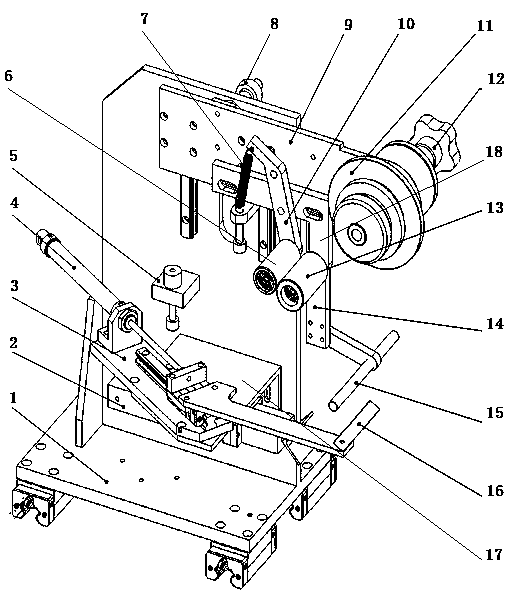

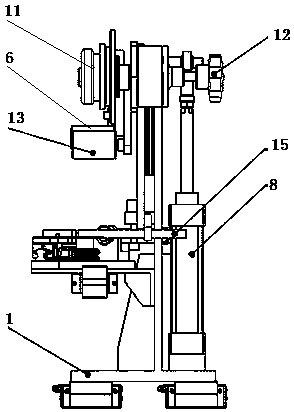

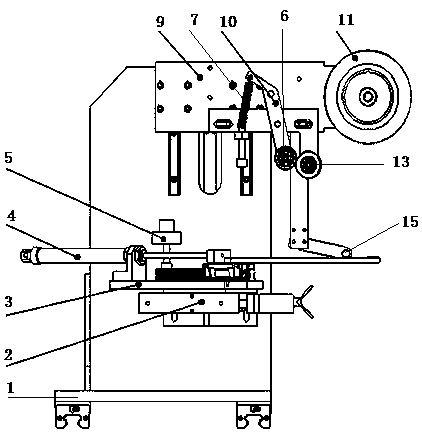

[0014] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Among them, the present invention is equipped with tape frame 9, tape cutting mechanism 3, tape frame moving cylinder 8 up and down, tape sticking mechanism 2, cylinder stroke limit block 5 on the mobile walking board support 1, and the moving walking board support 1 consists of a horizontal The walking board is connected with a vertical vertical board and a trapezoidal stiffener. The vertical vertical board is located on the upper surface of the horizontal walking board and is aligned with one end of the horizontal walking board. Bolt holes for fixing various parts are processed on the horizontal board and the vertical vertical board of the board support 1, and four nuts are installed on the four corners of the lower surface of the horizontal board of the mobile board support 1, and the upper part of the vertical board corresponds to the tape rack to move up and down The vertical direction of cylinder 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com