On-site defect-eliminating method for acquisition terminal and master station no-communication failures

A technology for collecting terminal and communication faults, applied in wireless communication, measuring devices, instruments, etc., can solve the problems of low collection operation and maintenance efficiency, large on-site operation and maintenance workload, and no terminal and main station.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

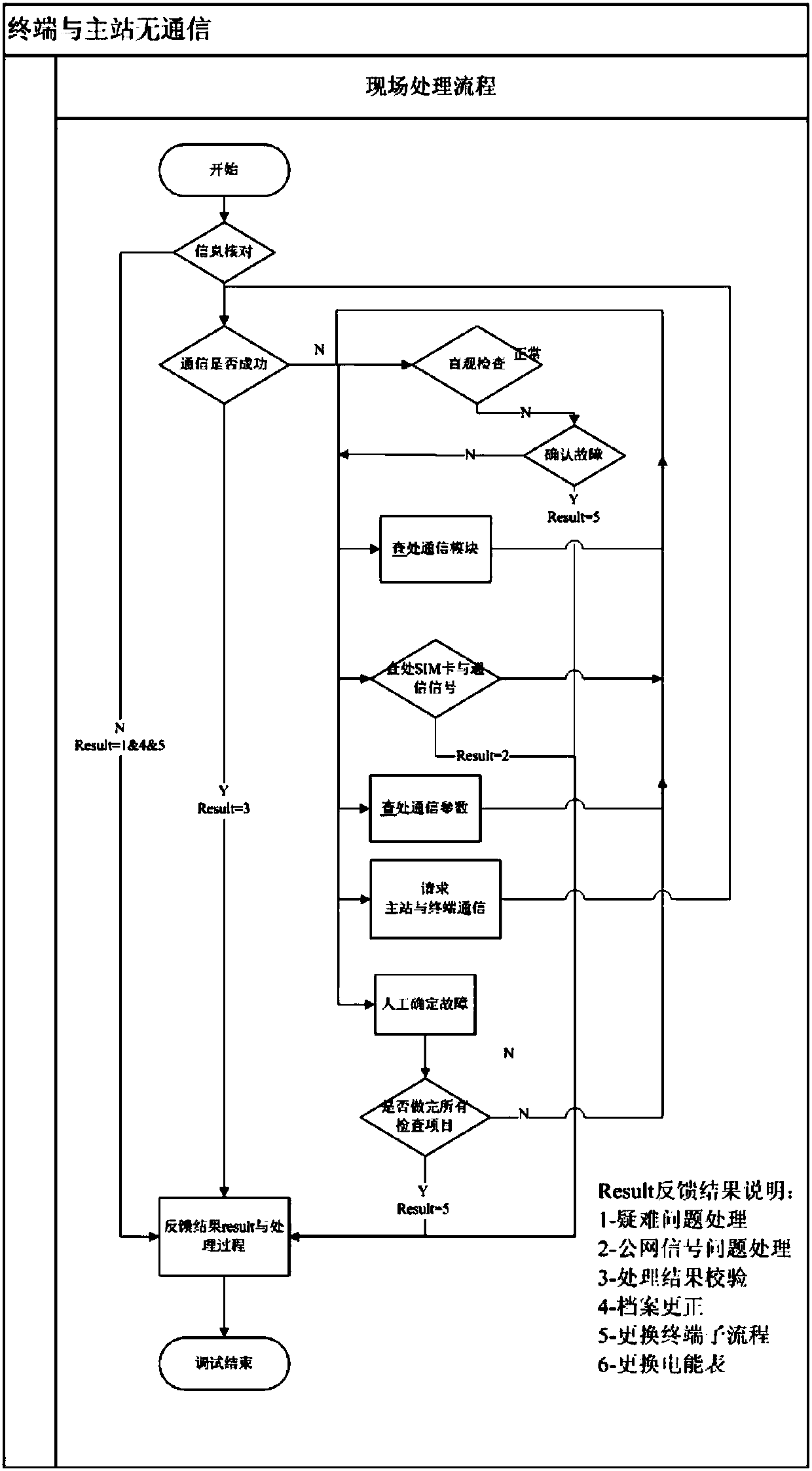

[0058] Such as figure 1 Shown, the present invention comprises the following steps:

[0059] 1) Information check: the collection operation and maintenance personnel check whether the on-site information is consistent with the system information, including checking the account number, terminal asset number, and electric energy meter asset number;

[0060] 2) Carry out various related inspections of the equipment according to the optimized sequence, including visual inspection, investigation of communication modules, investigation of SIM cards and communication signals, investigation of communication parameters, and determination of fault causes. The optimal sequence is based on historical fault records and fault logic of relevant inspection items Analyze and arrange relevant algorithms in order of priority;

[0061] 3) Carry out co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com