Control Method of Steam Turbine Shutdown and Shutdown System Based on Fault Critical Removal Time

A technology of critical cutting time and control method, which is applied to mechanical equipment, engine components, machines/engines, etc., can solve the problems of control logic and quick-close misoperation of steam turbine door-adjusting and fast-closing systems, and achieve avoidance of adverse effects, The effect of shielding fluctuations and preventing functional malfunction events

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

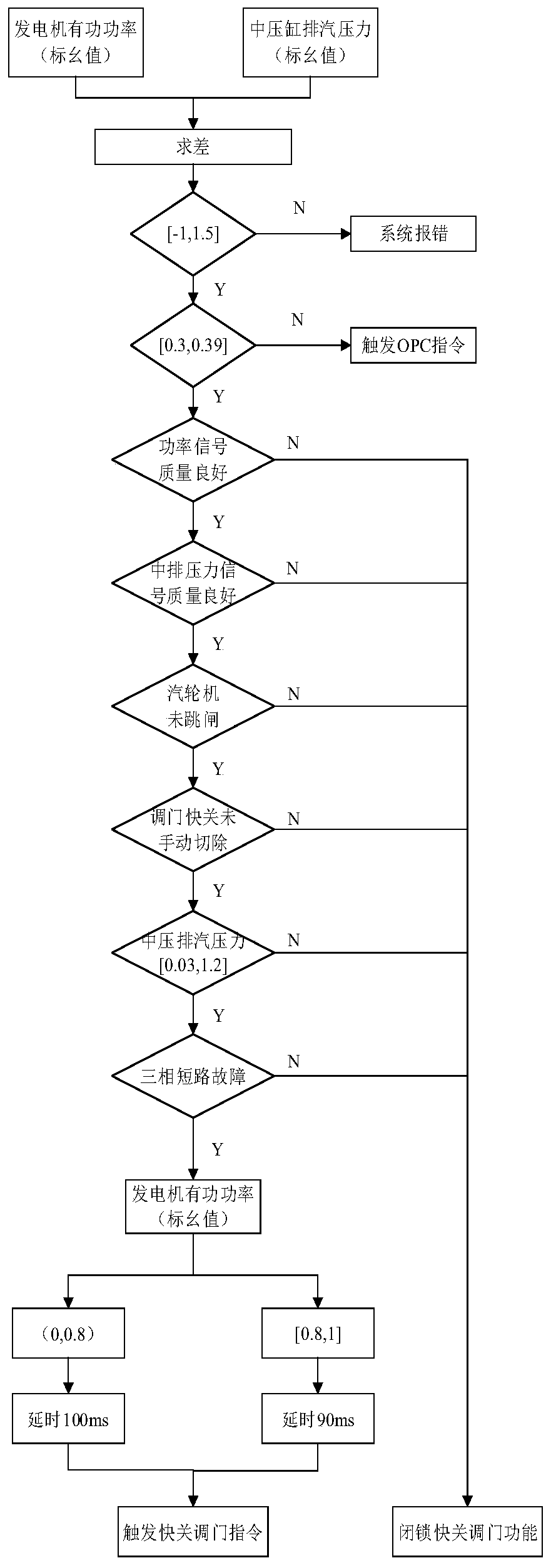

[0026] Such as figure 1 As shown, taking a 600MW unit produced by Harbin Steam Turbine Factory as the research object, when the power system fails and generates instantaneous fluctuations, the control logic of the valve and quick-closing system first controls the exhaust pressure of the medium pressure cylinder and the active power of the generator. The power is measured and the per unit value is taken to compare the difference. Only when the difference between the two is greater than -1 and less than 1.5, the data is considered accurate before subsequent judgment is made. Otherwise, the judgment logic will jump out and the system will report an error. If the difference is greater than 0.39, the overspeed protection (OPC) command will be triggered. If the difference is greater than 0.3, proceed to the next step of judgment; judge the signal of the steam turbine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com