Rolling brush device and method of use thereof

A rolling brush and roller technology, which is applied in the direction of construction and building construction, can solve the problems of uneven rolling brush and low efficiency, so as to improve the effect of rolling brush, prevent too much or too little liquid output, and prevent waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

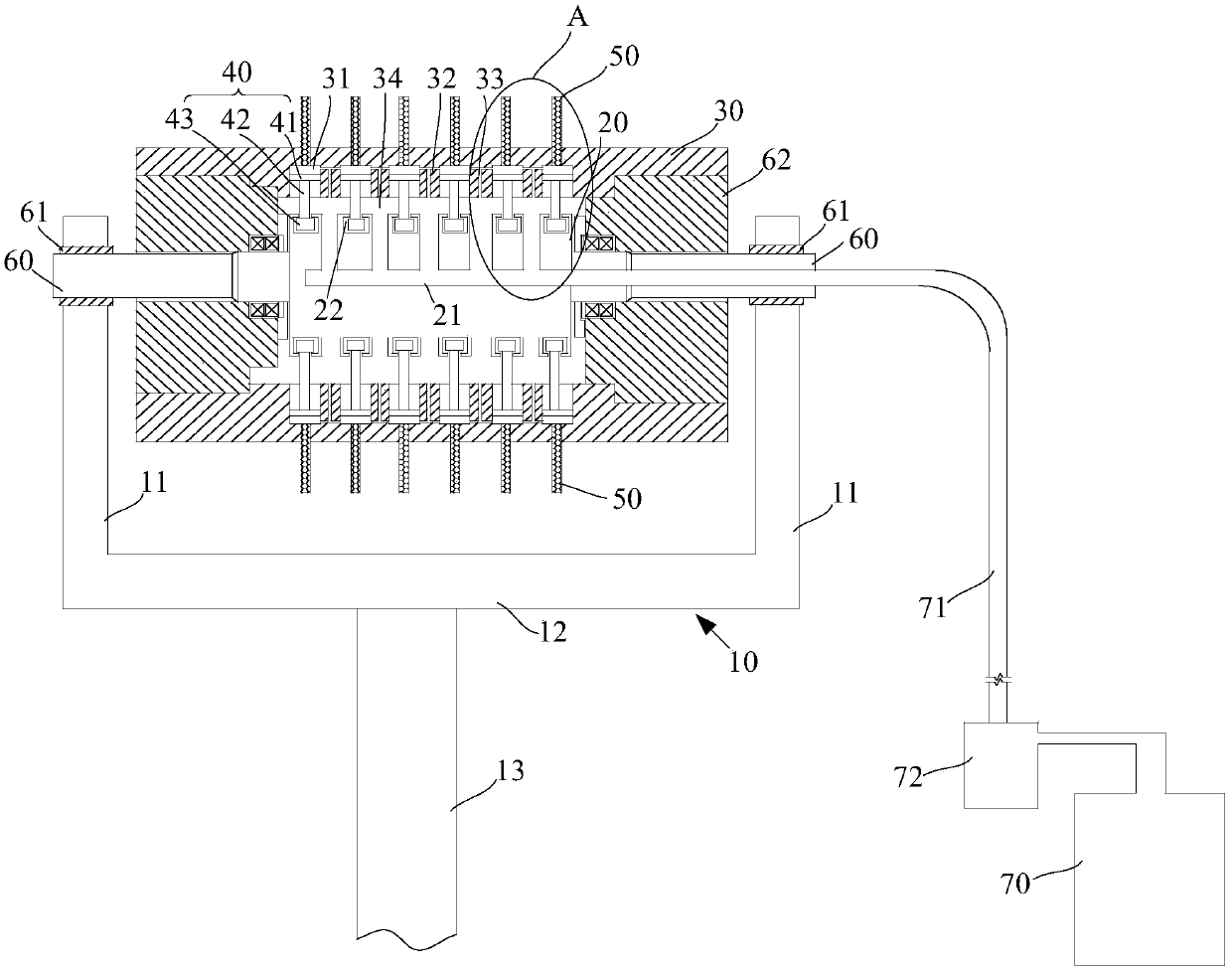

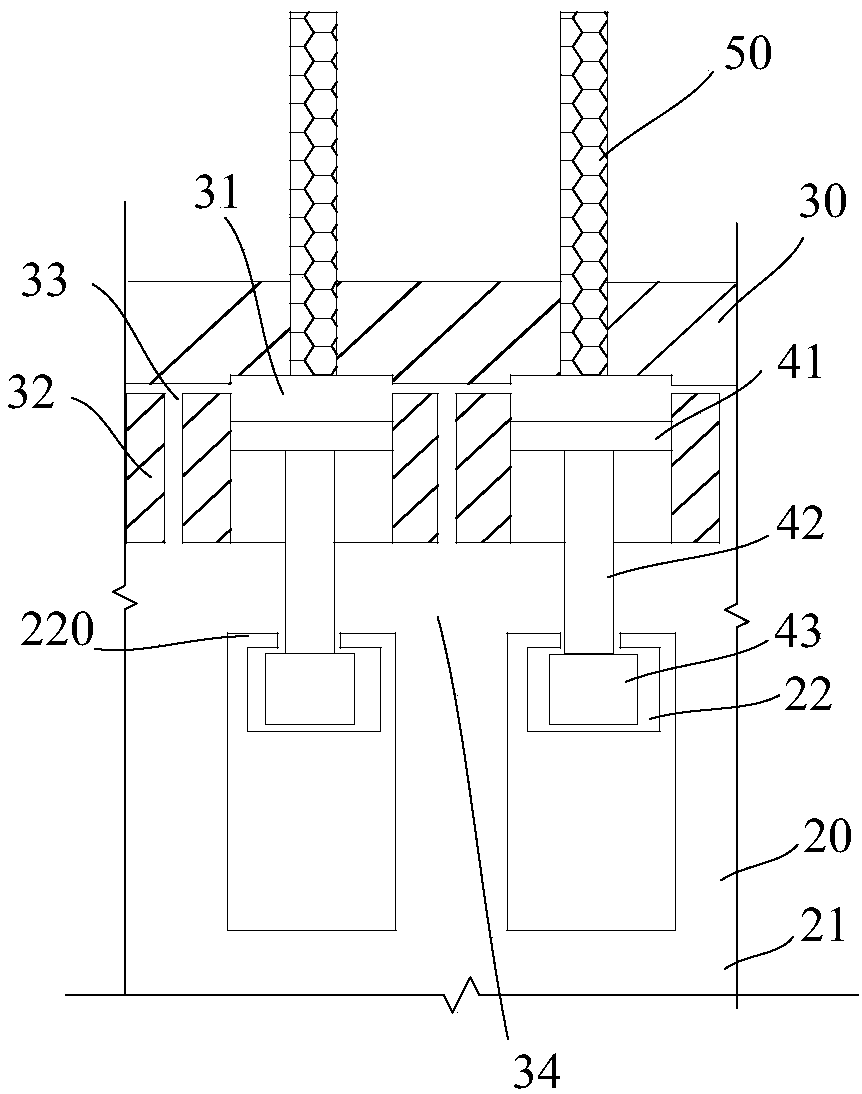

[0066] As a preferred embodiment of the rolling brush device of the present invention, the use method further includes providing spacer rings 32 arranged at intervals along the axial direction of the housing 30 and vertically fixed to the inner wall of the housing 30 , two adjacent spacer rings A piston chamber 31 is formed between 32; a conveying flow channel 33 is opened on the separating ring 32, and the conveying flow passage 33 is connected to the piston chamber 31; the roller brush liquid in the liquid inlet flow passage 21 is sucked into the piston chamber 31, including: The brush fluid is adsorbed from the liquid inlet channel 21 into the delivery channel 33 , and the brush fluid in the delivery channel 33 is absorbed into the piston cavity 31 .

[0067] Further, a storage cavity 34 is formed enclosed between the casing 30 and the eccentric roller 20 , and the storage cavity 34 is connected between the liquid inlet channel 21 and the piston cavity 31 . The storage cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com