An automatic detachment device for underwater mooring chains

An automatic dismantling and mooring chain technology, applied in the direction of ships, etc., can solve the problems of high platform risk, long replacement cycle, high cost, etc., and achieve the effect of high replacement efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

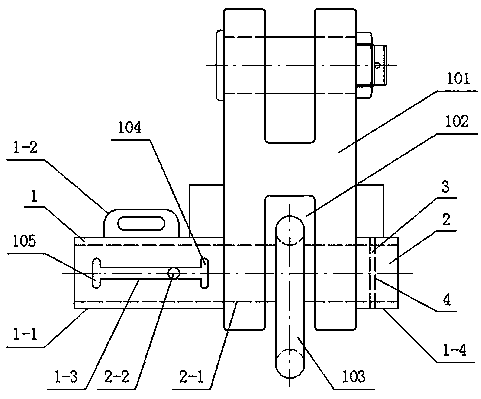

[0023] An automatic detachment device for underwater mooring chains, comprising a shackle 101 and a link 103 connected in a groove 102 on the shackle 101; the side wall of the shackle 101 is also welded with a fixed structure 1 The link 103 is connected to the fixed structure 1 and the shackle 101 through the detachable structure 2; the fixed structure 1 and the detachable structure 2 are connected by a sliding structure, which is more convenient for installation and disassembly; The structure 1 includes a first structure arranged on the left side wall of the shackle 101, and a second structure arranged on the right side wall of the shackle 101; the first structure includes a first guide rail 1-1, and a connection The handle 1-2 on the side wall of the first guide rail 1-1; the side wall of the first guide rail 1-1 is also provided with a track 1-3; the plane projection of the track 1-3 is I-shaped Structure: In the I-shaped structure, when the drawbar 2-2 drives the pin shaft...

no. 2 example

[0025] An automatic detachment device for underwater mooring chains, comprising a shackle 101 and a link 103 connected in a groove 102 on the shackle 101; the side wall of the shackle 101 is also provided with a fixed structure 1 The link 103 is connected to the fixed structure 1 and the shackle 101 through the detachable structure 2; the fixed structure 1 and the detachable structure 2 are connected by a sliding structure; the fixed structure 1 and the detachable There is also a safety pin 3 between the structures 2; the second guide rail 1-4 and the pin shaft 2-1 are provided with a through hole 4 for installing the safety pin 3; in actual use, the safety pin 3 is provided to cooperate with the The inside of the through hole 4 is more conducive to the connection and fixation of the fixed structure 1 and the detachable structure 2, and the reliability is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com