A combined assembly method of three-axis turntable inner frame components

A three-axis turntable and combined assembly technology, which is applied to workbenches, manufacturing tools, etc., can solve problems such as difficulty in ensuring the accuracy of the mounting surface, and achieve the effects of good consistency, guaranteed positional accuracy, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

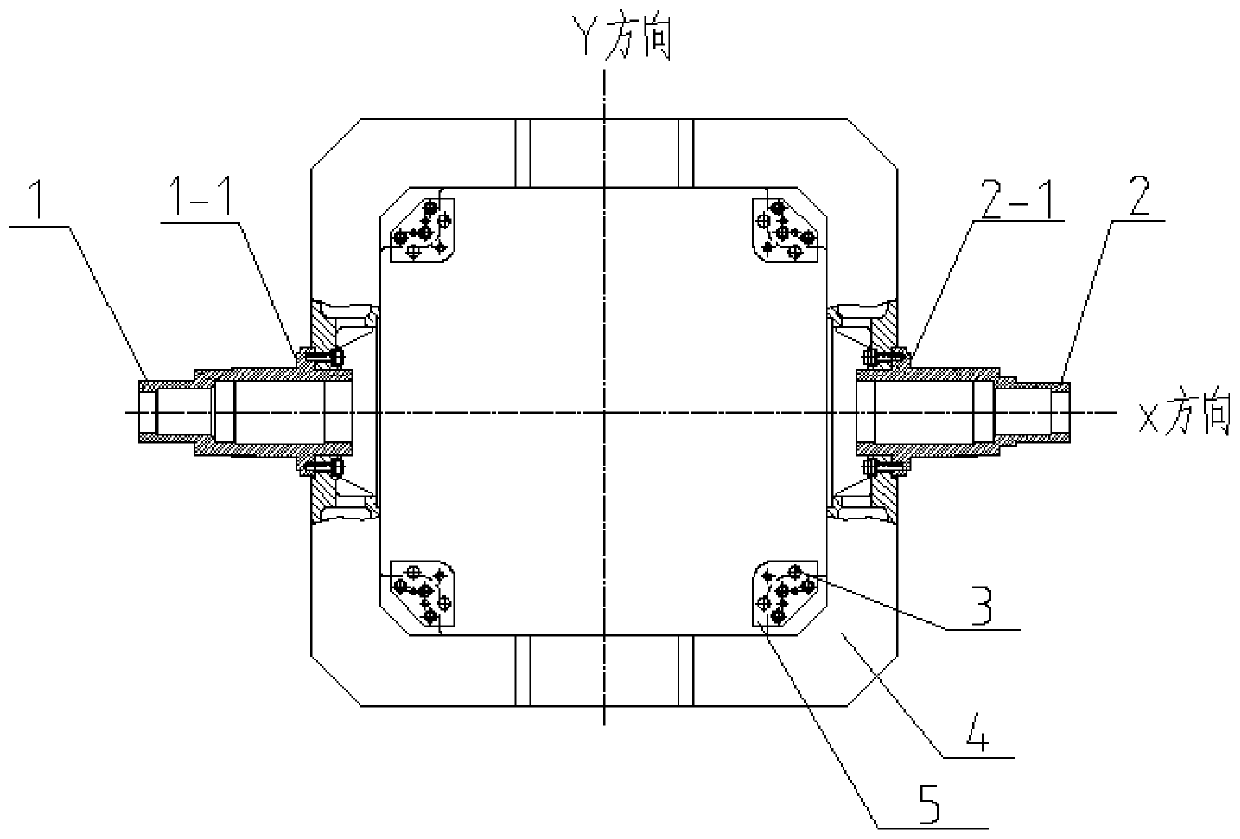

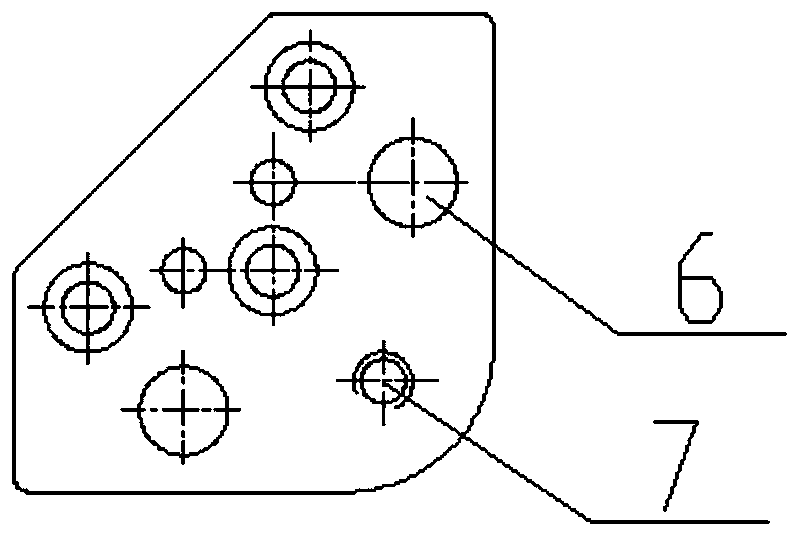

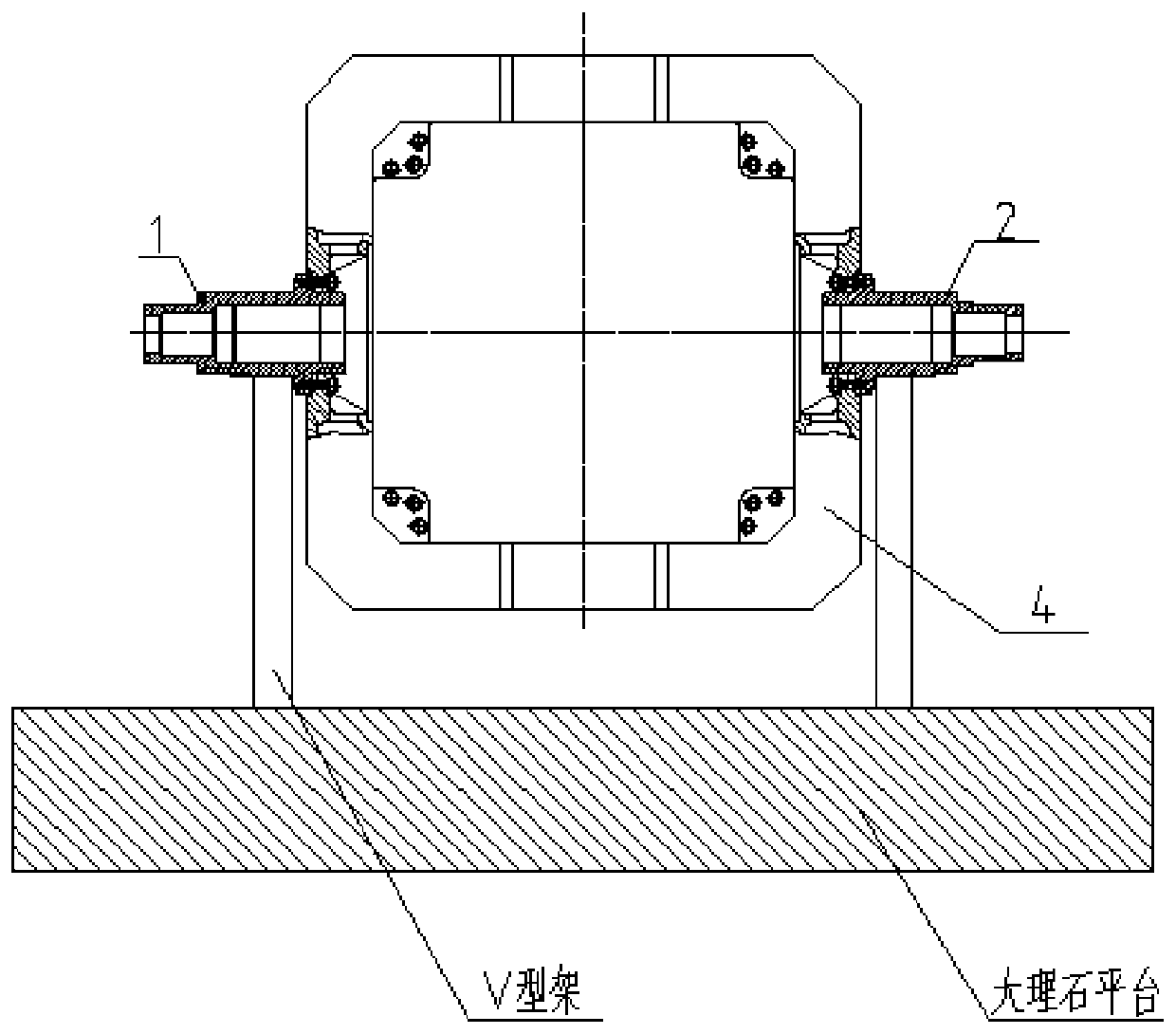

[0034] Such as figure 1 , figure 2 As shown, the inner frame assembly of the three-axis turntable is composed of the inner frame 4, the inner frame trunnion (left) 1, the inner frame trunnion (right) 2, the product installation block 5, a total of 4, and the pin 3, a total of 3 components. Threaded hole 7 and pin hole 6 are arranged on block 5, and pin 3 is installed in pin hole 6 by pin. In order to ensure the parallelism of the product mounting block 5 to the axis of the inner frame 4, the dimensional accuracy of the threaded hole 7 on the product mounting block 5, and the precision of the pin 3, it is necessary to meet the accuracy requirements through assembly and testing.

[0035] Install the inner frame trunnion (left) 1 and the inner frame trunnion (right) 2 symmetrically in the mounting hole of the inner frame 4, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com