Gas microflow measurement device and method based on laser interferometry

A technology of laser interference and measurement devices, which is applied in the directions of measurement devices, liquid/fluid solid measurement, flow measurement/mass flow, etc. It can solve problems such as low precision and inability to meet the requirements of precise traceability of vacuum values, and achieve high precision, The measurement method is simple and easy, and the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

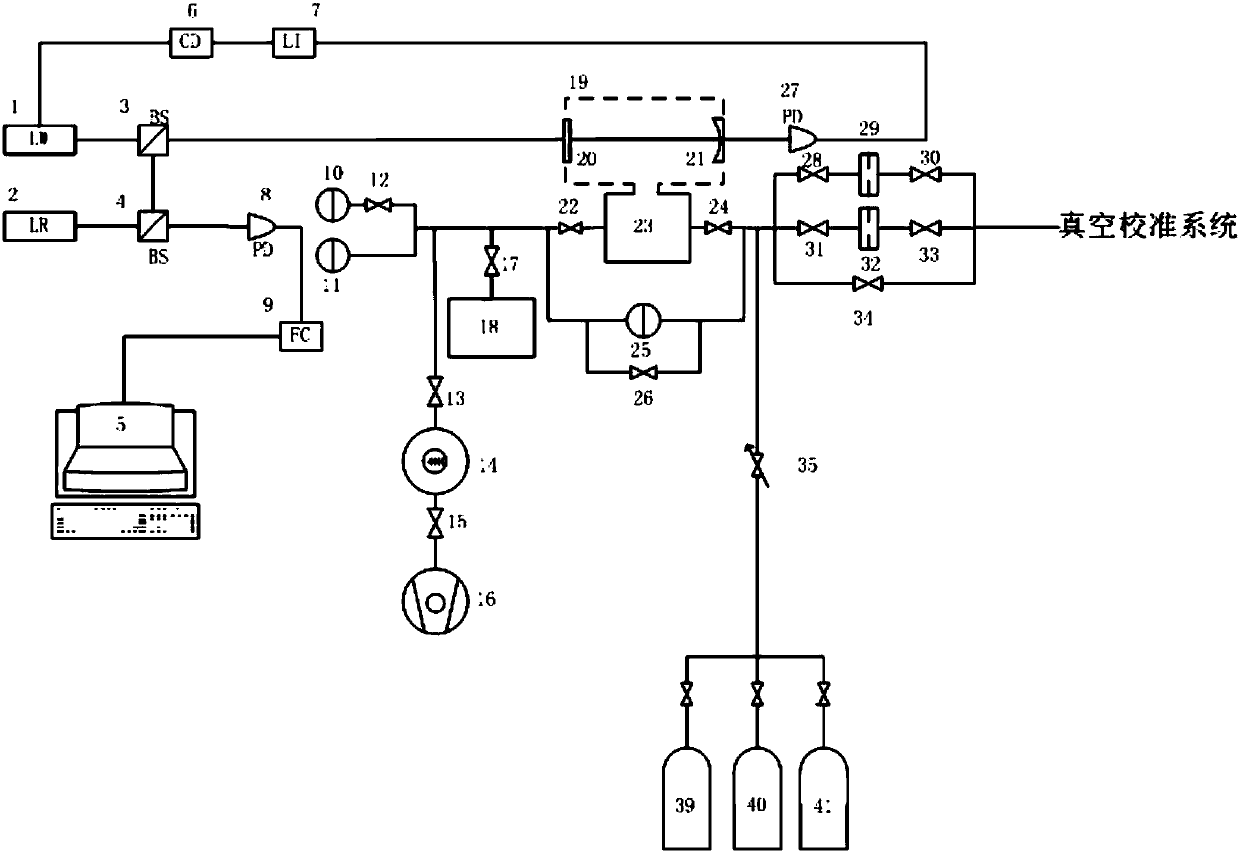

[0030] In the vacuum range, the pressure is low, the air is thin, and the measurement accuracy of gas micro-flow is not high. The invention provides a gas micro-flow measurement device based on laser interferometry. The measurement device includes a flowmeter vacuum device and a laser interferometer. Connect the laser interferometer with the pressure-stabilizing chamber of the vacuum device of the flowmeter, and use the relationship between the frequency measured by the laser interferometer and the micro-flow rate of the gas to obtain the standard flow value.

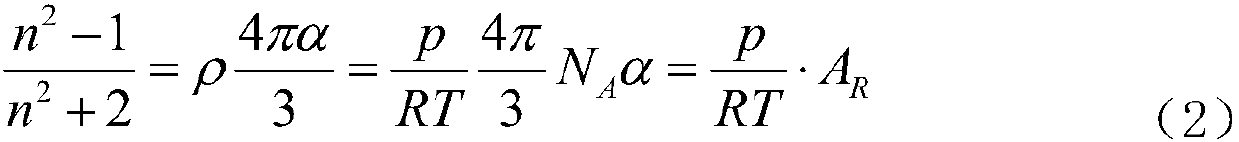

[0031] Due to the fixed conductance method, the flow Q generated by the gas microflowmeter is determined by the gas density and the conductance of the fixed conductance element, as shown in formula (1).

[0032] Q=ρkTC (1)

[0033] In the formula,

[0034] ρ-molecule number density, m -3 ;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com