A modular cold source equipment

A modular and equipment technology, applied in lighting and heating equipment, water shower coolers, indirect heat exchangers, etc., can solve problems such as time-consuming, unmatched design capacity and installation capacity of cold source systems, etc. Guarantee the speed of implementation, avoid equipment size and installation space mismatch, and ensure the effect of system requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

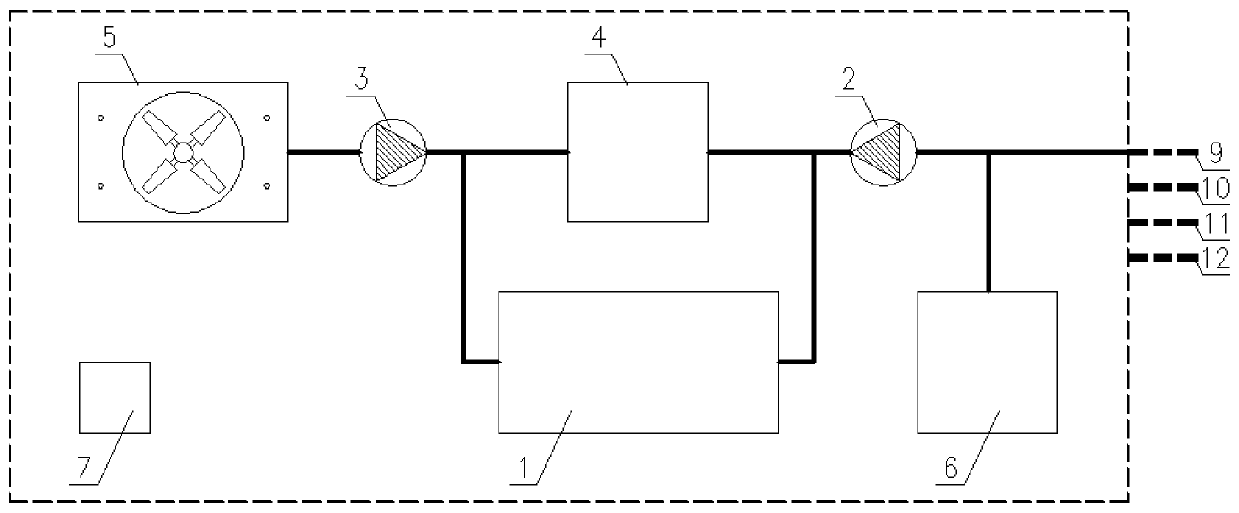

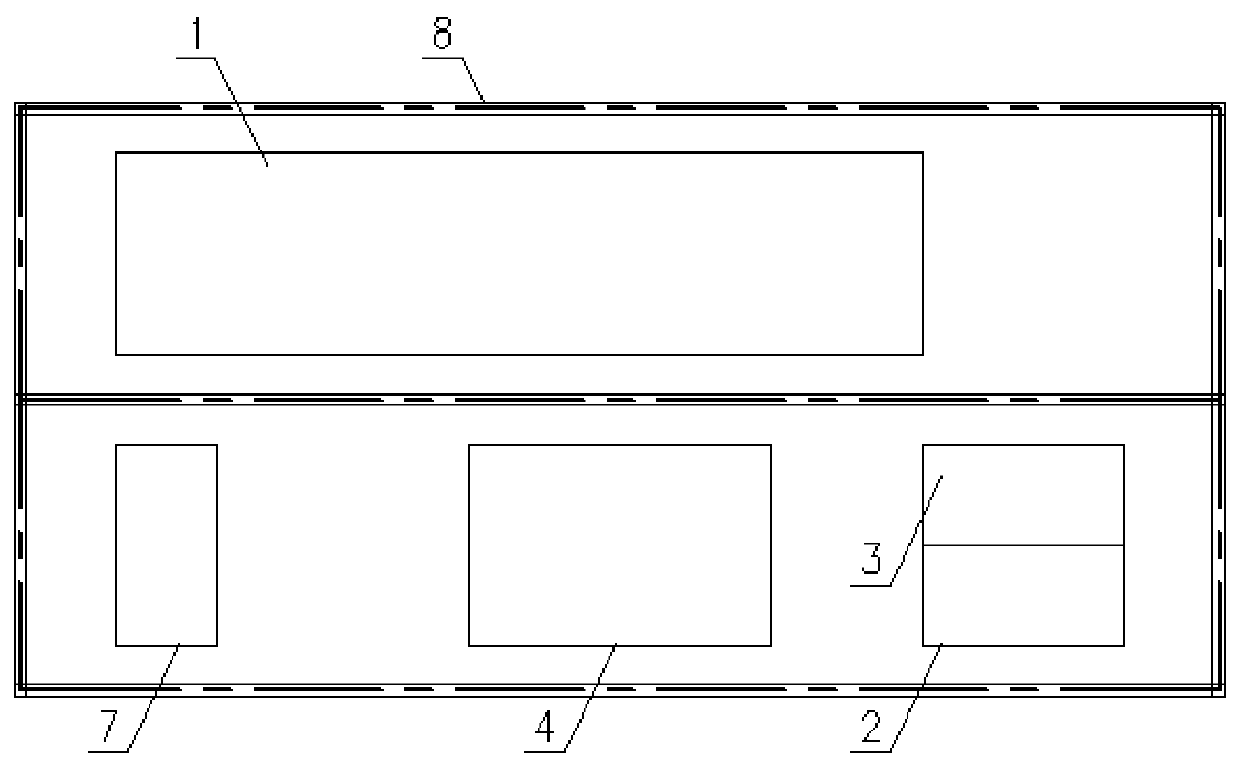

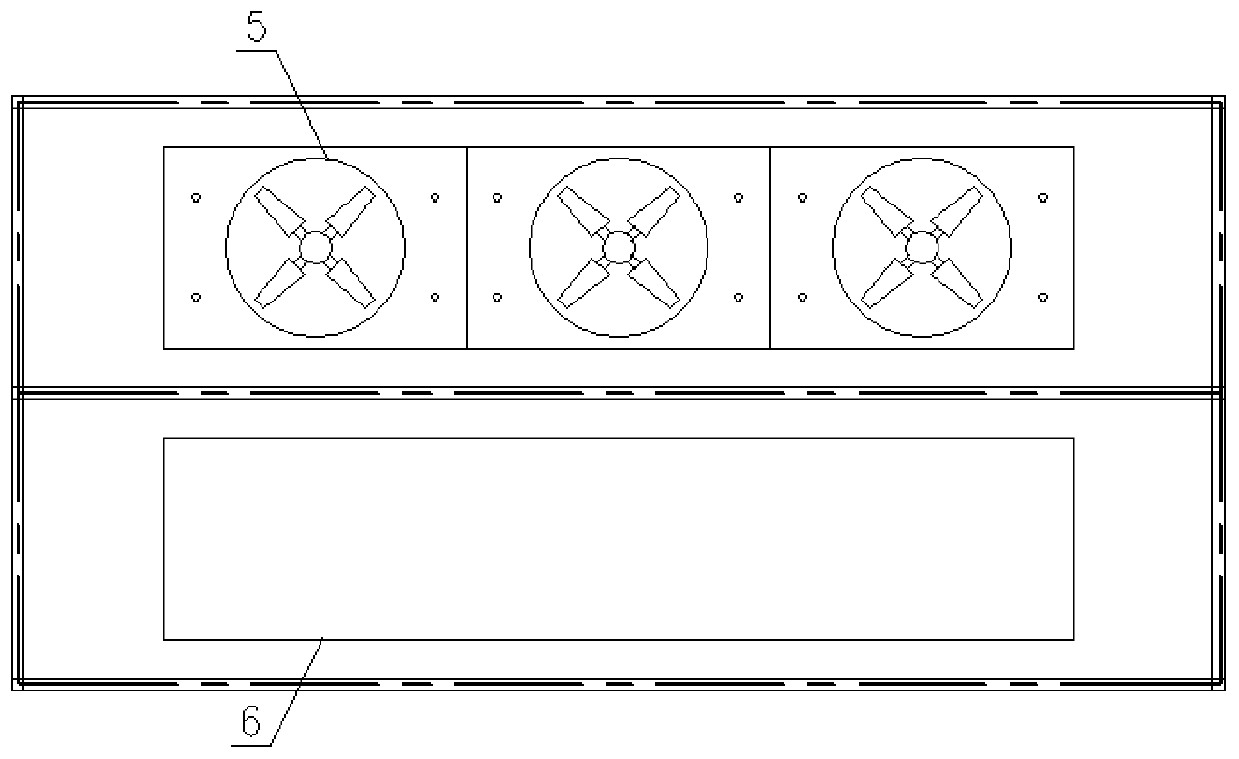

[0014] The present invention provides a modular cold source equipment, wherein the modular cold source equipment includes a frame, a chiller, a cooling tower, a cooling water pump, a plate heat exchanger, and a chilled water pump integrated in the frame The power distribution cabinet and / or control cabinet in the frame, and the interface unit located outside the frame. Wherein, the cooling water pump is connected with the cooling tower, the plate heat exchanger, and the chiller unit, and the chilled water pump is connected with the plate heat exchanger and the chiller unit. Wherein, the modular cold source equipment is connected with other equipment through the interface unit.

[0015] Preferably, the interface unit is used exclusively for connection with other devices. Preferably, the chilled water, water replenishment, power supply, monitoring / communication systems outside the modular cold source equipment are considered as a whole, and designed according to the concept of qui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com