Pastry conveying system

A conveying system and pastry technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of low production efficiency, wasted labor, and high production costs, achieve fast material distribution, reduce manual intervention, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

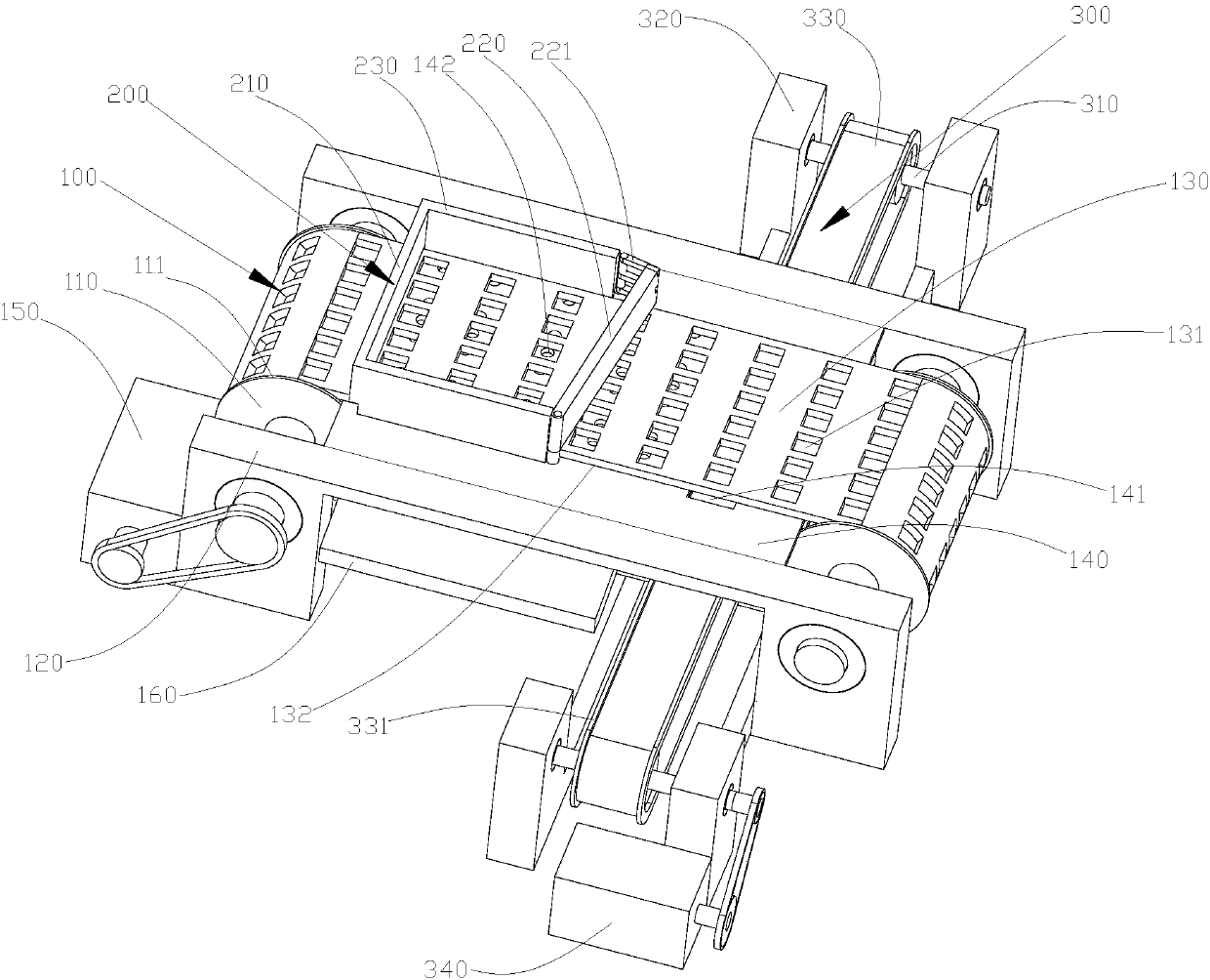

[0019] Such as figure 1 As shown, a noodle cake conveying system is disclosed in this embodiment, including a material distribution device 100, and the material distribution device 100 includes two transmission rollers 110 and two oppositely arranged support frames 120, and the two transmission rollers 110 It is erected between the two support frames 120 through bearings, and the two drive rollers 110 are located at the two ends of the two support frames 120 respectively; 130, the distribution conveyor belt 130 is provided with evenly arranged through holes 131; a pallet 140 is erected between the two support frames 120, and the pallet 140 penetrates the distribution conveyor belt 130 from the side to form cavity 132, and the supporting plate 140 is close to the distribution conveyor belt 130 at the top of the cavity 132, and the end of the supporting plate 140 away from the feeding end of the distribution conveyor belt 130 is provided with a discharge opening 141, the length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com