Multipurpose cold press

A cold press, a pair of technology, applied in the field of cold press, can solve the problems of non-adjustable distance, non-adjustable hydraulic cylinder distance, and inability to adjust the lower platen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

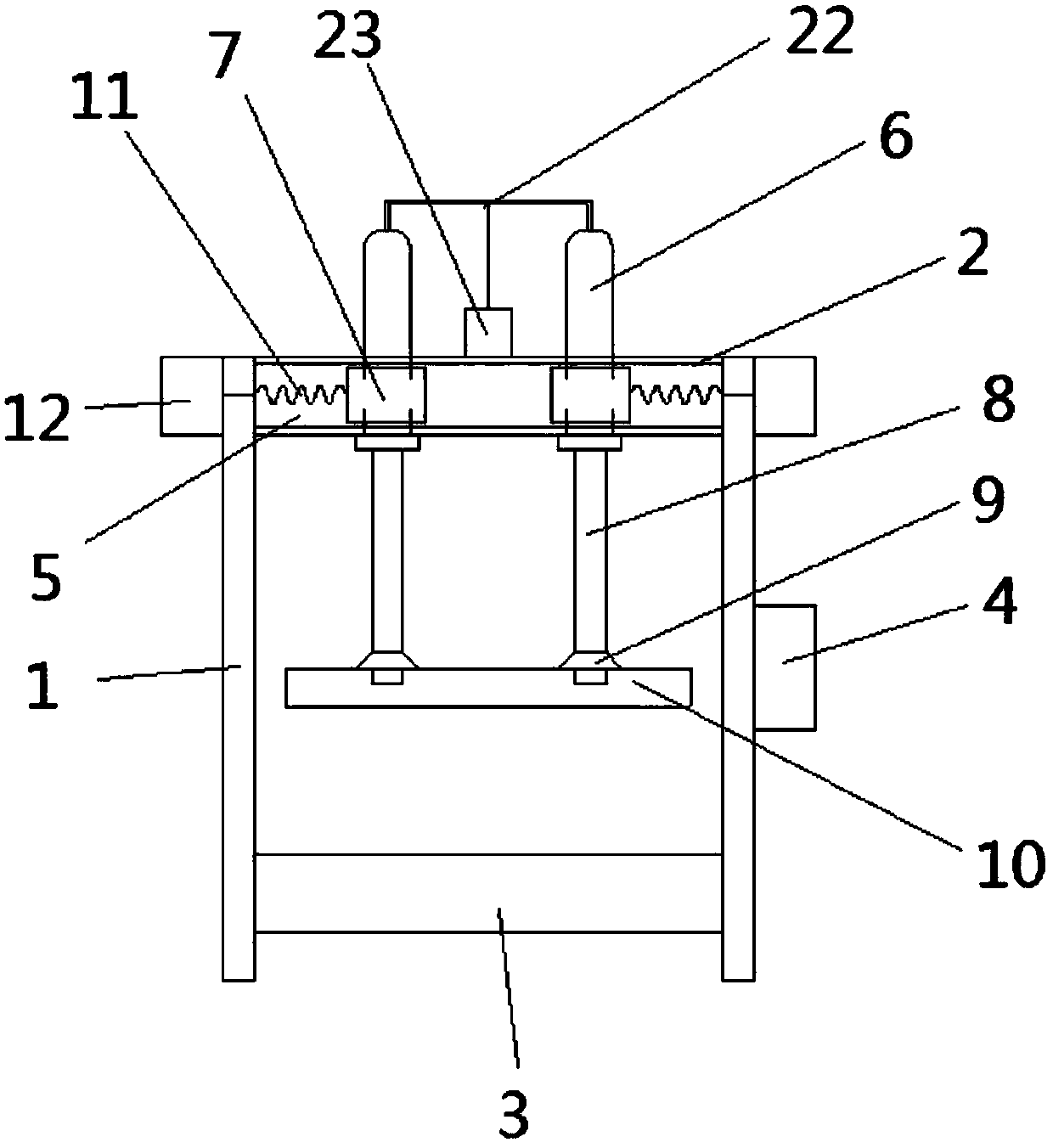

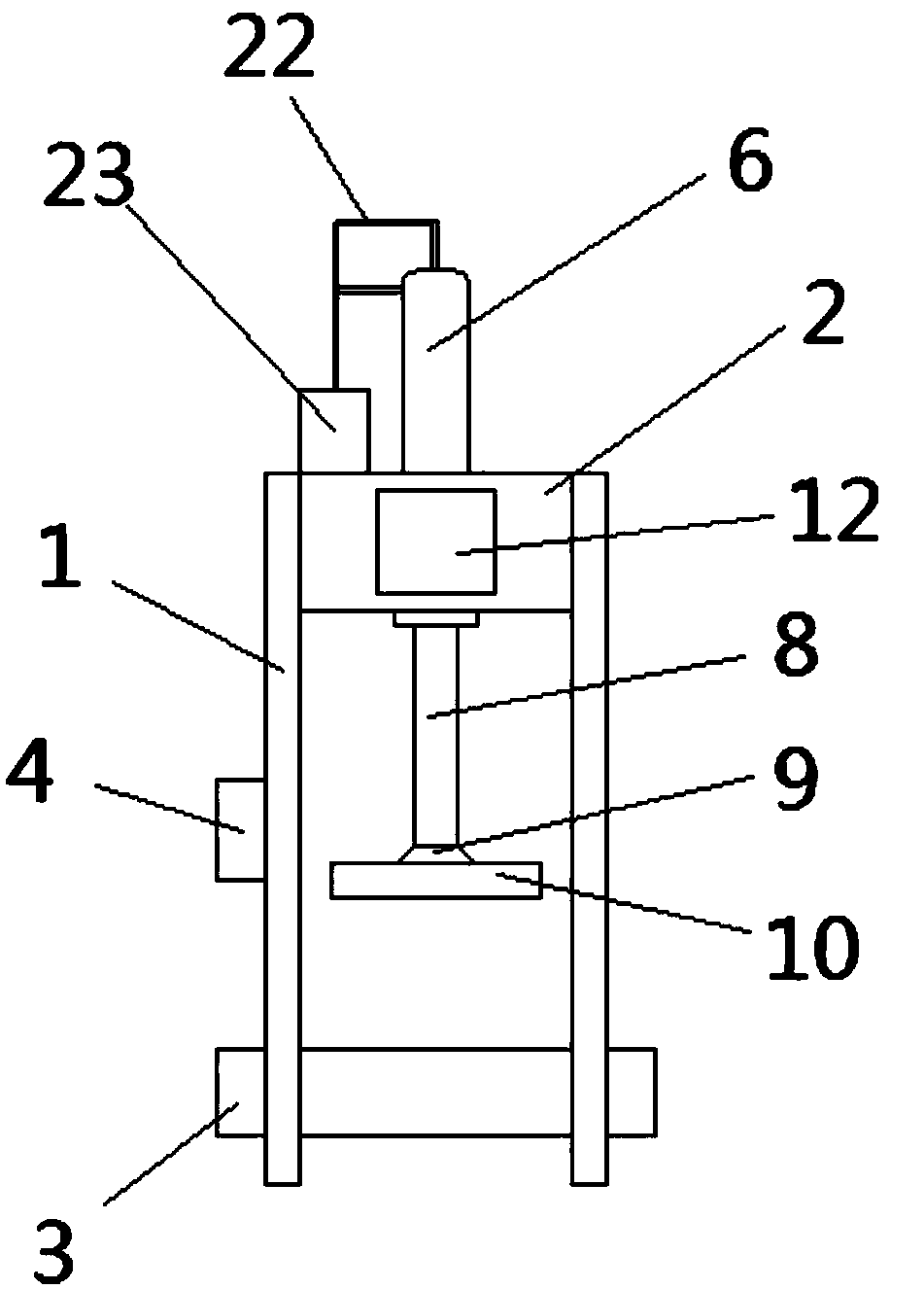

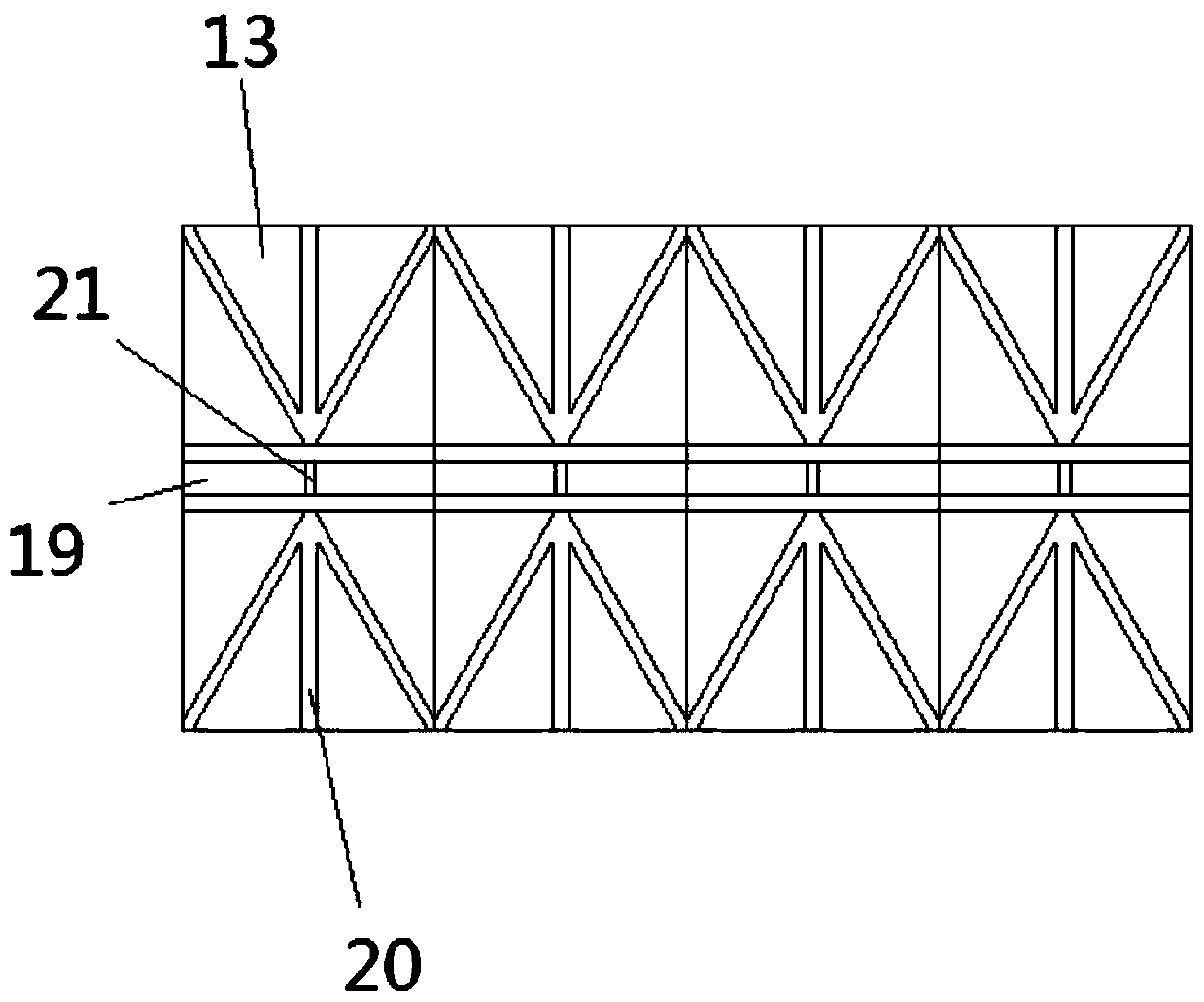

[0015] Embodiment: a kind of multipurpose cold press, structure such as Figures 1 to 6 As shown, it includes a pair of columns 1, an upper top plate 2 and a lower bottom plate 3 are respectively arranged between the columns 1, and an electric control cabinet 4 is arranged on the column 1; There is a pair of hydraulic cylinders 6, and the hydraulic cylinders 6 are connected to the slideway 5 through the slider 7 arranged in the slideway 5. The piston rod 8 is connected to the bottom of the hydraulic cylinder 6, and the bottom of the piston rod 8 is connected to the lower pressure plate through the pressure block 9. 10. The sliders 7 are all connected to the push rod motor 12 through the screw rod 11; the lower pressing plate 3 includes several lower pressing plate monomers 13 that are tenon-jointed, and the lower pressing plate monomer 13 includes a bottom layer 14, a middle layer 15 and a top layer 16, One end of the middle layer 15 is provided with a tenon 17, and the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com