Metal bar cutting machine

A metal bar and cutting machine technology, which is applied to metal processing machinery parts, metal processing equipment, shearing devices, etc., can solve the problems of human injury, sparks splashing from the grinder, copper slag flying everywhere, etc., and prolong the use The effect of long life, good cutting precision and convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

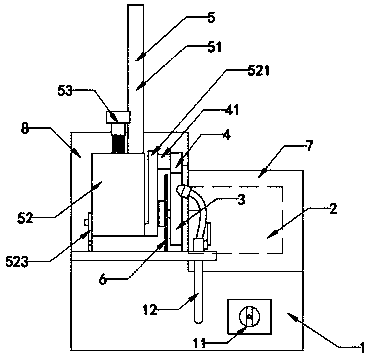

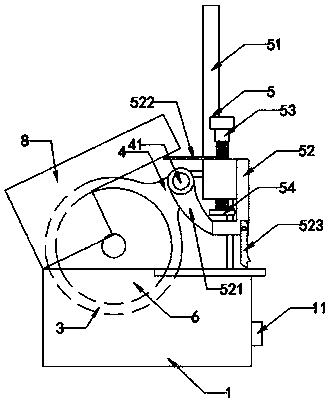

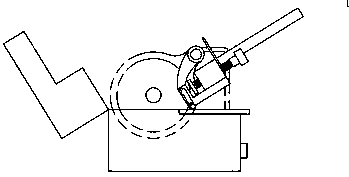

[0014] Depend on figure 1 Known, a kind of metal bar material cutting machine, comprises chassis 1, and described chassis 1 side is provided with driving device 2, and driving device 2 is also fixedly connected with fixing bracket 3 at one end of main shaft, and fixing bracket 3 is provided with convex 4, the projection 4 is provided with a shaft column 41, the shaft column 41 is movably connected with a clamping mechanism 5, the main shaft is provided with a cutter 6, and the clamping mechanism 5 is provided with a handle 51; For the metal bar, the handle 51 drives the clamping mechanism 5 to rotate with the shaft 41 as a fulcrum, and the metal bar is sent to the position of the cutter 6 for cutting. The clamping mechanism 5 is composed of a handle 51, a fixed block 52, an adjusting bolt 53 and a clamping block 54. The bottom of the fixed block 52 is provided with a crank 521 that is movably connected to the shaft column 41, and the handle 51 is fixed on the top of the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com