Filter device for chemical engineering experiment

A filtration device and experimental technology, applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., can solve the problems of no connection device at the inlet of the raw liquid, insufficient filtration, etc., and achieve protection from corrosion and firmness. effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific embodiments.

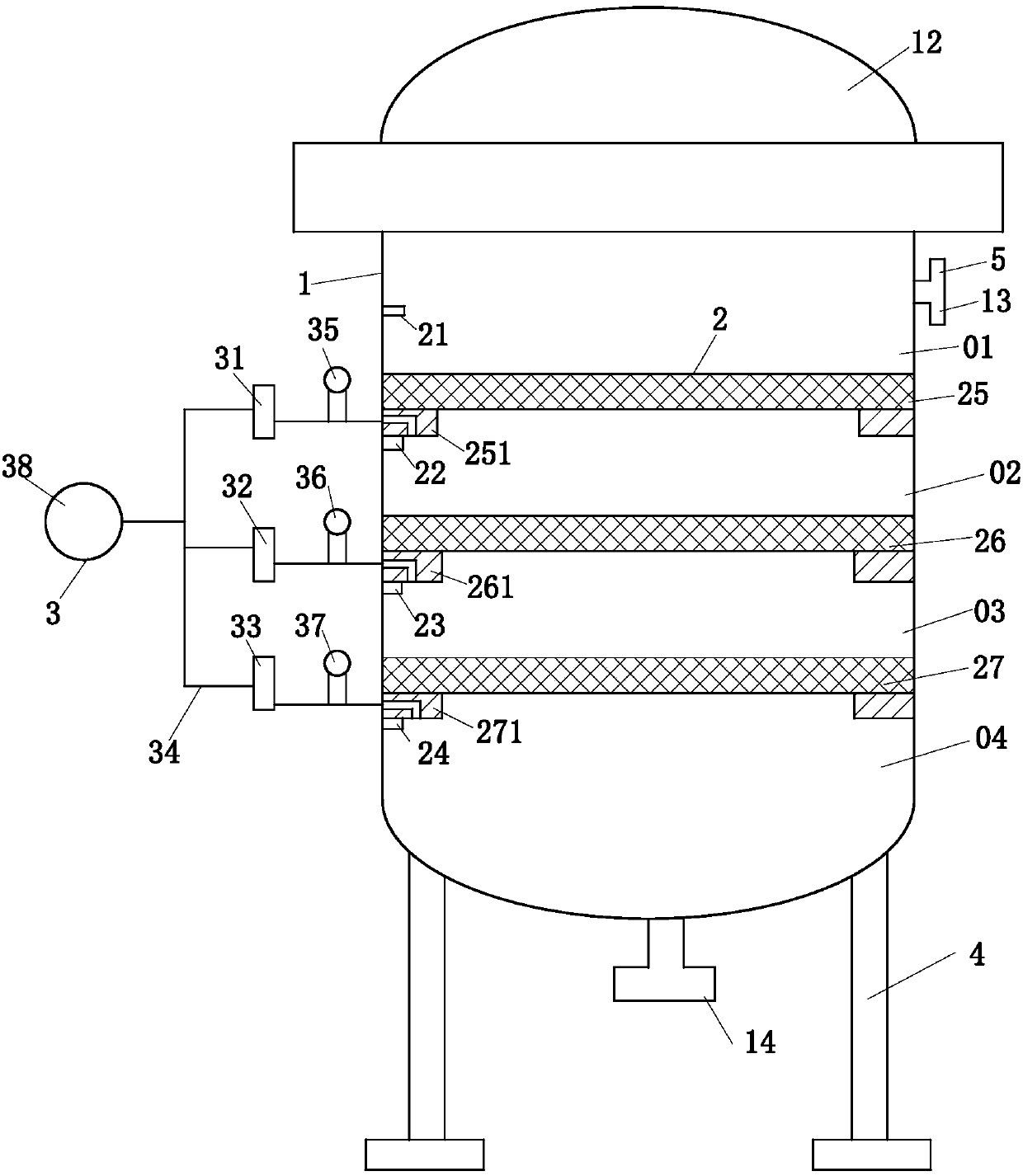

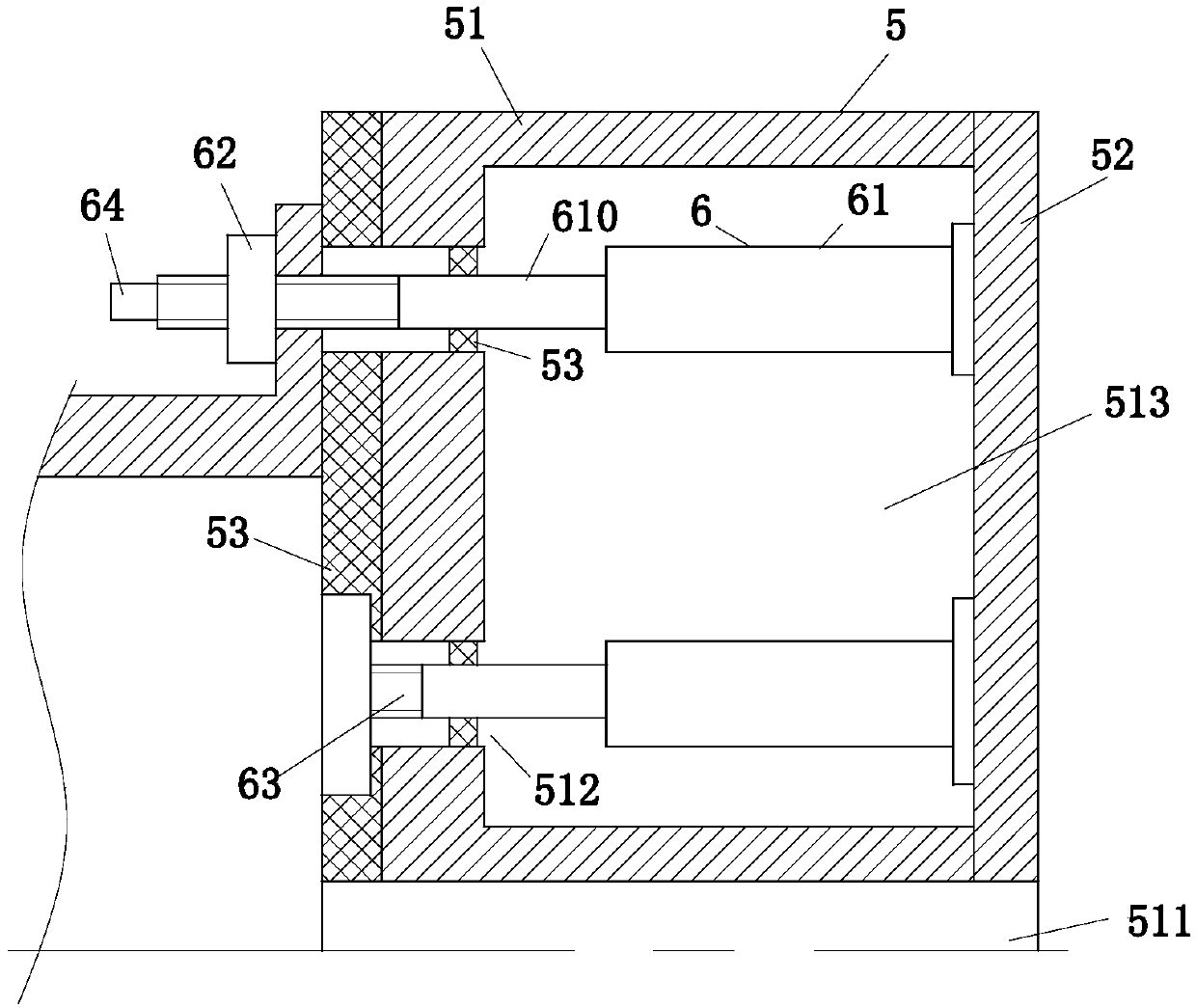

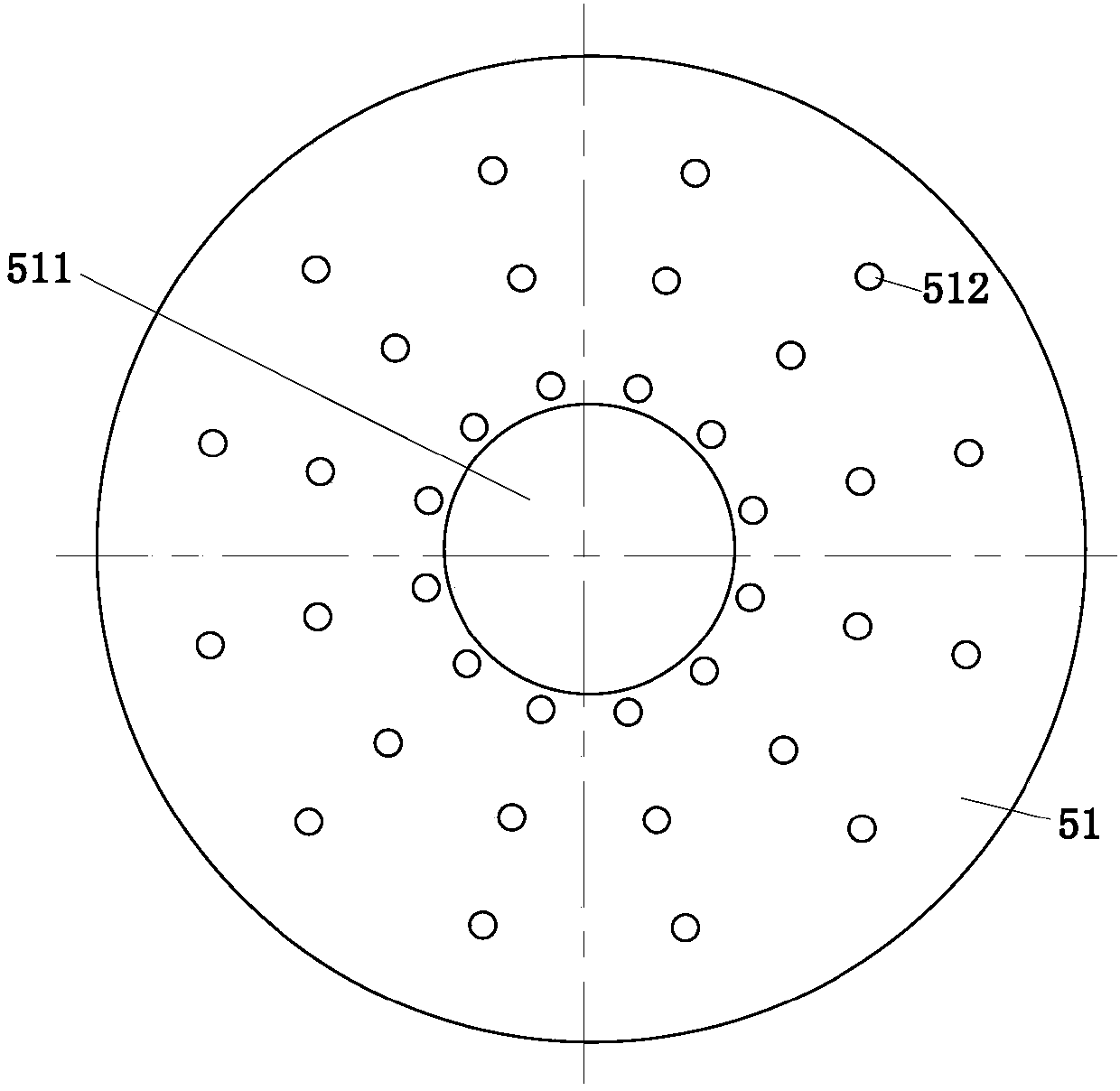

[0028] Such as Figure 1 to Figure 6 As shown, a filter device for chemical experiments according to the present invention includes a tank body 1, an end cover 12, a liquid inlet 13, a liquid outlet 14, a filter module 2, a first liquid level sensor 21, a second The liquid level sensor 22, the third liquid level sensor 23, the fourth liquid level sensor 24, the air pressure control module 3 and the bracket 4, and the filter module 2 is arranged inside the tank body 1, and the filter module 2 is provided with a first-stage filter in sequence from top to bottom Net 25, secondary filter screen 26 and three-stage filter screen 27, one-stage filter screen 25 is installed on the first electromagnetic positioning block 251, and secondary filter screen 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com