A driving waveform debugging method for a three-color electronic paper module

A technology of driving waveforms and debugging methods, which is applied in the field of electronic paper, can solve problems such as poor contrast and unsatisfactory display effects, and achieve the effects of guaranteed contrast and display effects, good display effects, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] A driving waveform debugging method for a three-color electronic paper module, comprising the following steps:

[0030] (1) if figure 1 As shown, determine the voltage value of the common pole Vcom 1: connect the three-color electronic group module 4 to the control board. The control board is an existing technology, and it will not be shown here. Detection equipment 3, detection equipment 3 such as a multimeter, set the Vcom 1 pin to be suspended, and control the screen to alternately update the full-screen black and full-screen white, repeat several cycles, observe and record the voltage value displayed by the multimeter when the black and white screen is switched, take The average value is the voltage value of Vcom 1;

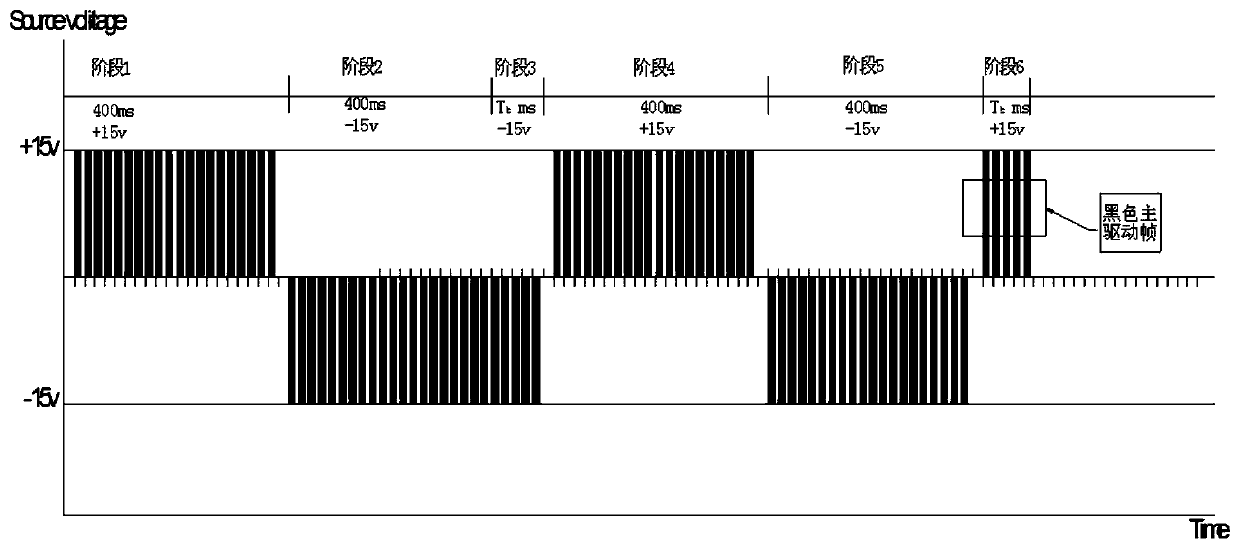

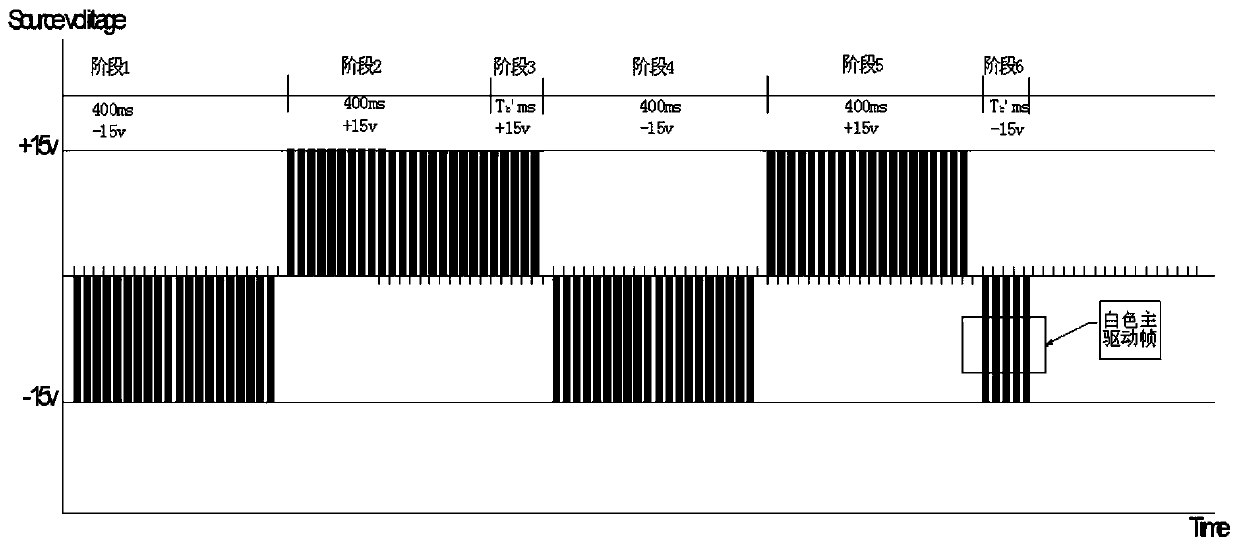

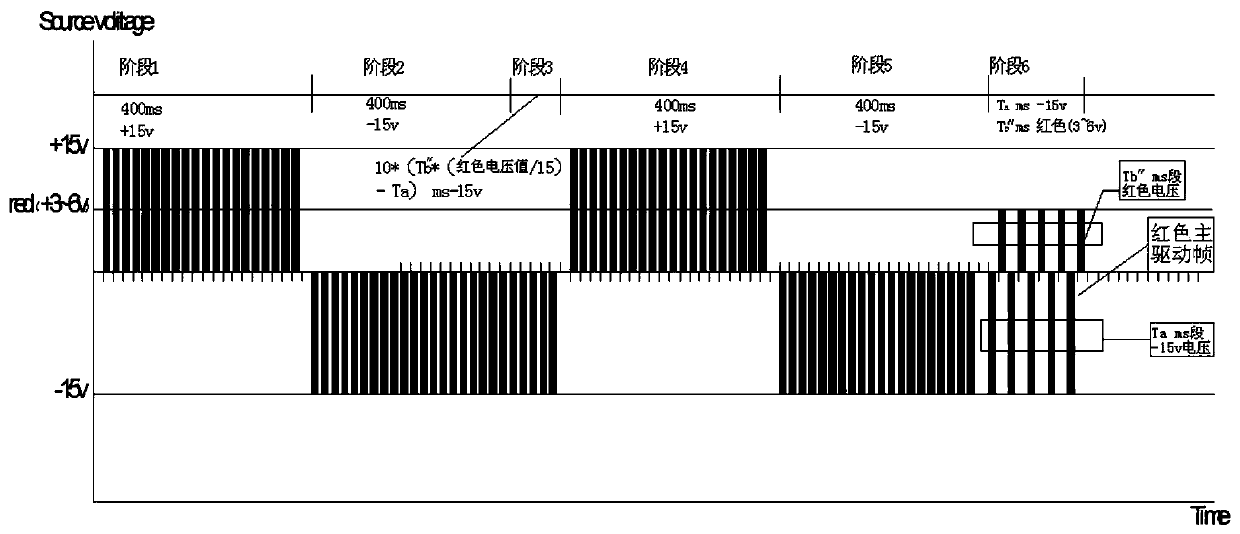

[0031] (2) Determine the main driving frame: the main driving frame includes black main driving frame, white main driving frame and red main driving frame, respectively use black screen standard test waveform, white screen standard test waveform and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com