Continuous integration pipeline system based on automated operation and maintenance and method thereof

A continuous integration and assembly line technology, applied in software maintenance/management, version control, data processing applications, etc., can solve problems such as inability to reduce costs, lack of standardization and automation, and stay at the concept and process level, to improve online efficiency, The effect of improving application quality and reducing enterprise management costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

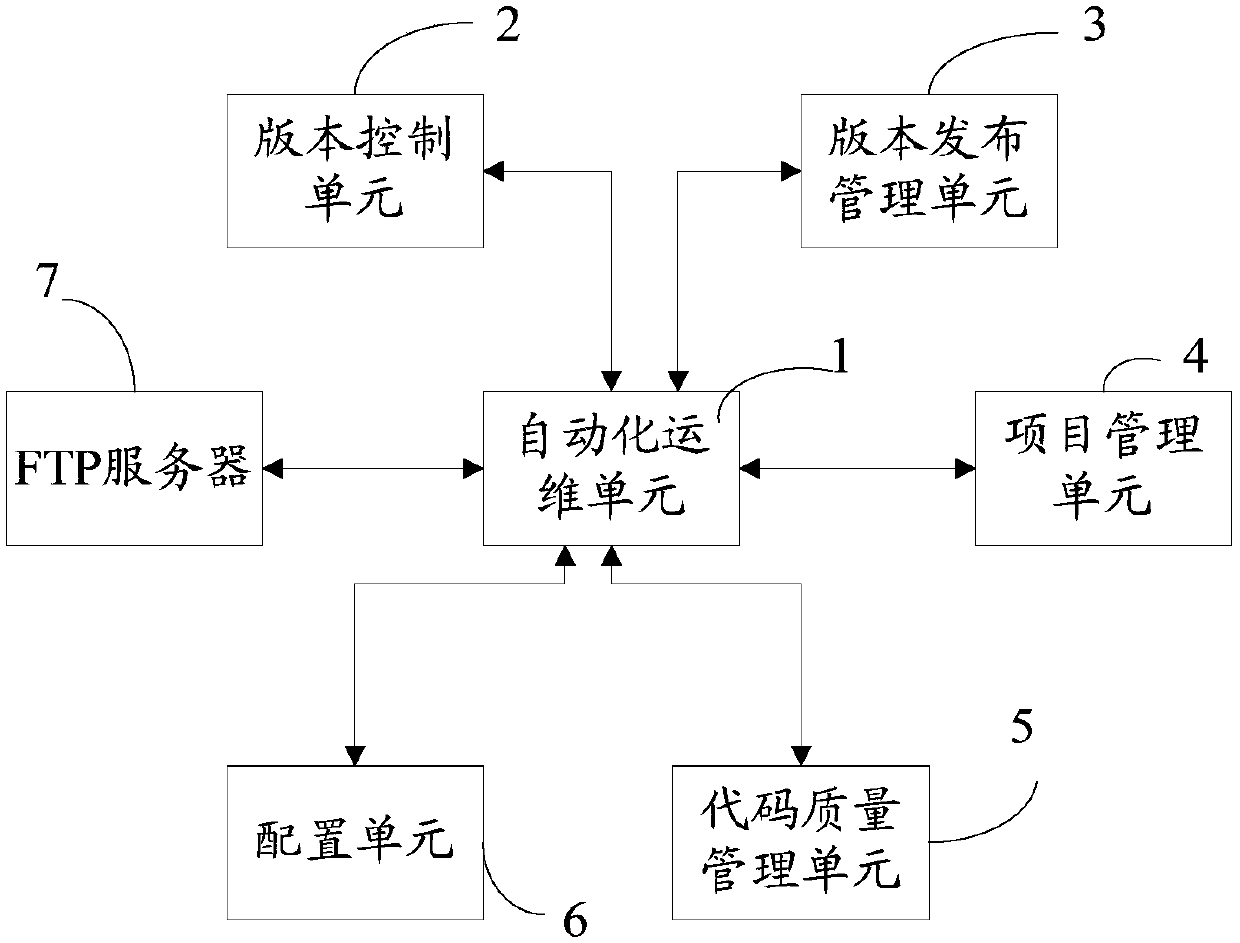

[0055] Such as Figure 1-8 In the specific embodiment shown, the continuous integration pipeline system based on automated operation and maintenance provided by this embodiment can be used in the continuous integration pipeline process of application launch, to realize the application of the DEVOPS concept, through the standardization of technical platforms, automated execution and implementation of continuous Integration improves application quality and reduces enterprise management costs.

[0056] Such as figure 1 As shown, this embodiment provides a continuous integration pipeline system based on automated operation and maintenance, which includes an automated operation and maintenance unit 1, a version control unit 2, a version ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com