Textile equipment cleaning device facilitating thread residue disengaging

A textile equipment and cleaning device technology, which is applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of not being able to reach or not being able to clean a single part with water vapor, and achieve high flexibility, Efficient and convenient equipment, efficient and convenient cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

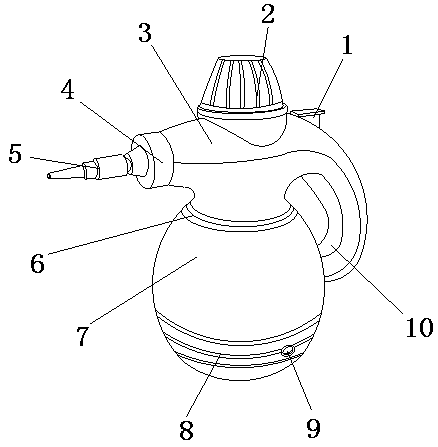

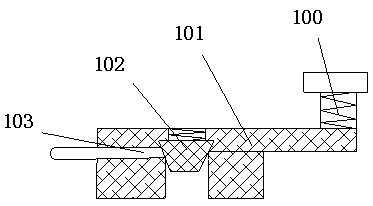

[0020] see Figure 1-Figure 3 , the present invention provides a textile equipment cleaning device that facilitates thread removal: its structure includes: linkage button switch 1, water injection screw cap 2, cleaning machine upper shell cover 3, nozzle fixing block 4, water vapor nozzle 5, fastening rubber ring 6 , cleaning machine lower shell 7, volatilization stirring tank 8, charging slot 9, hand grip block 10, said hand grip block 10 is vertically welded on the right side of the cleaning machine upper shell cover 3 and the cleaning machine lower shell 7, The linkage button switch 1 is vertically installed on the handle block 10, the nozzle fixing block 4 is fixed with the water vapor nozzle 5, and the fastening rubber ring 6 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com