Bottom knife broken line knife

A technology of dotted line knife and bottom knife, which is applied in the direction of metal processing, etc., can solve the problems of waste and inability to conveniently discharge materials, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

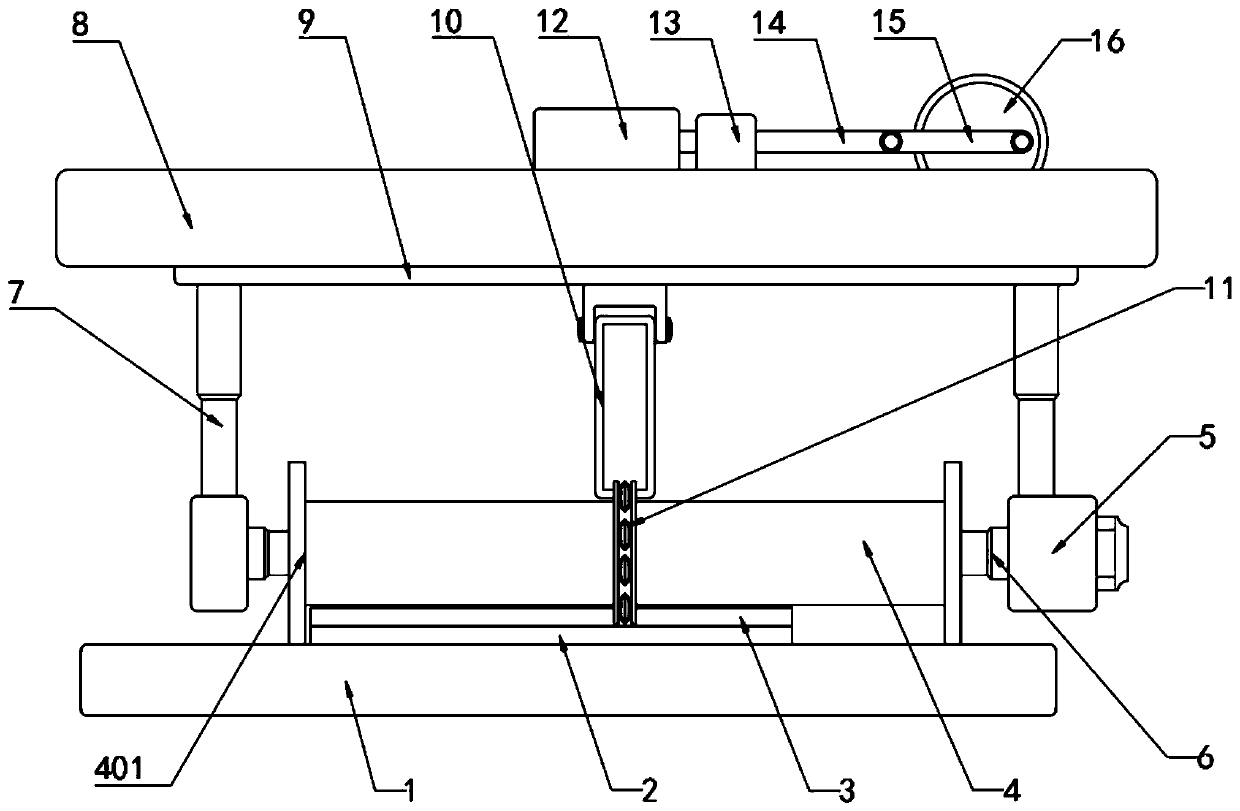

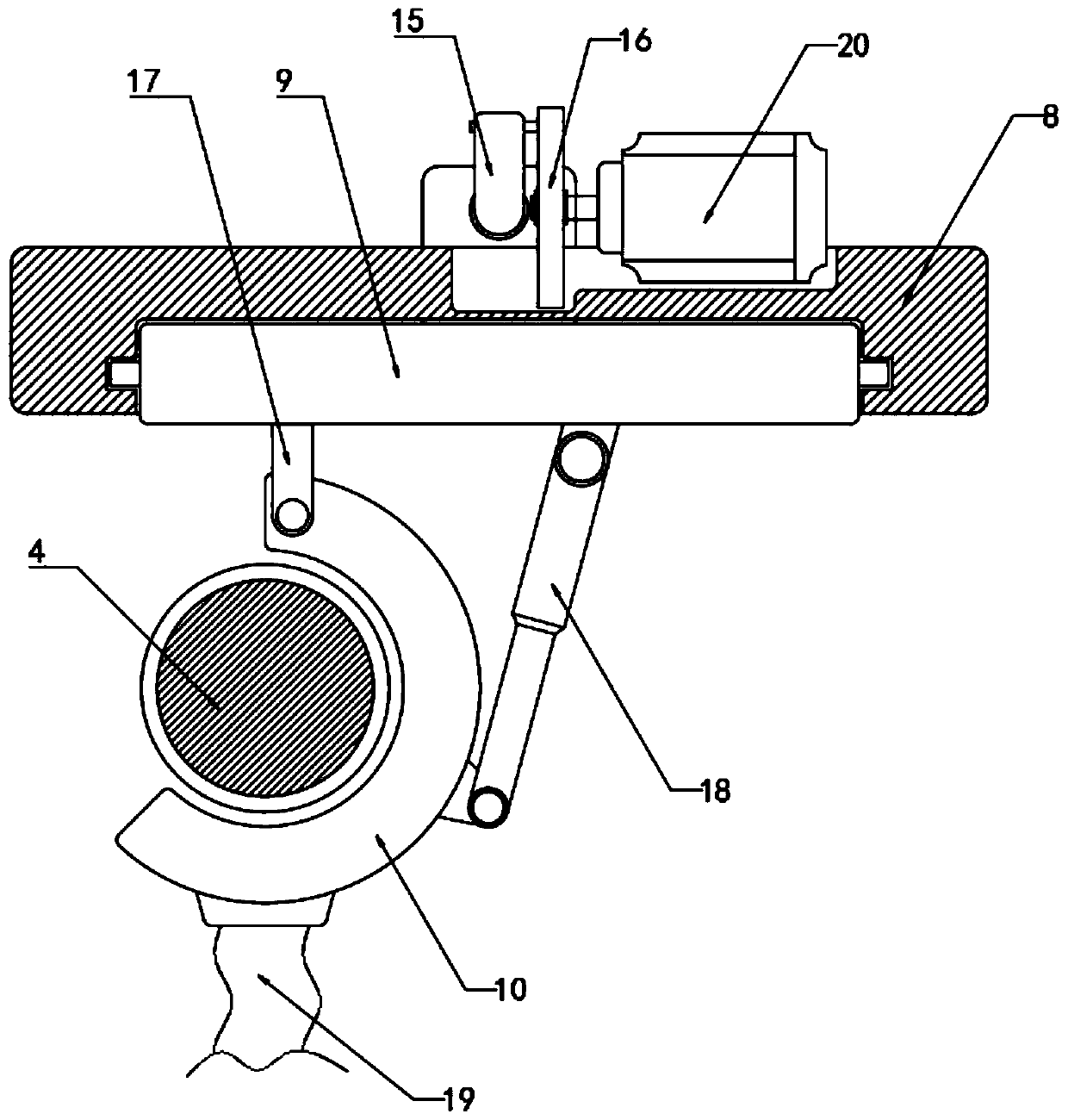

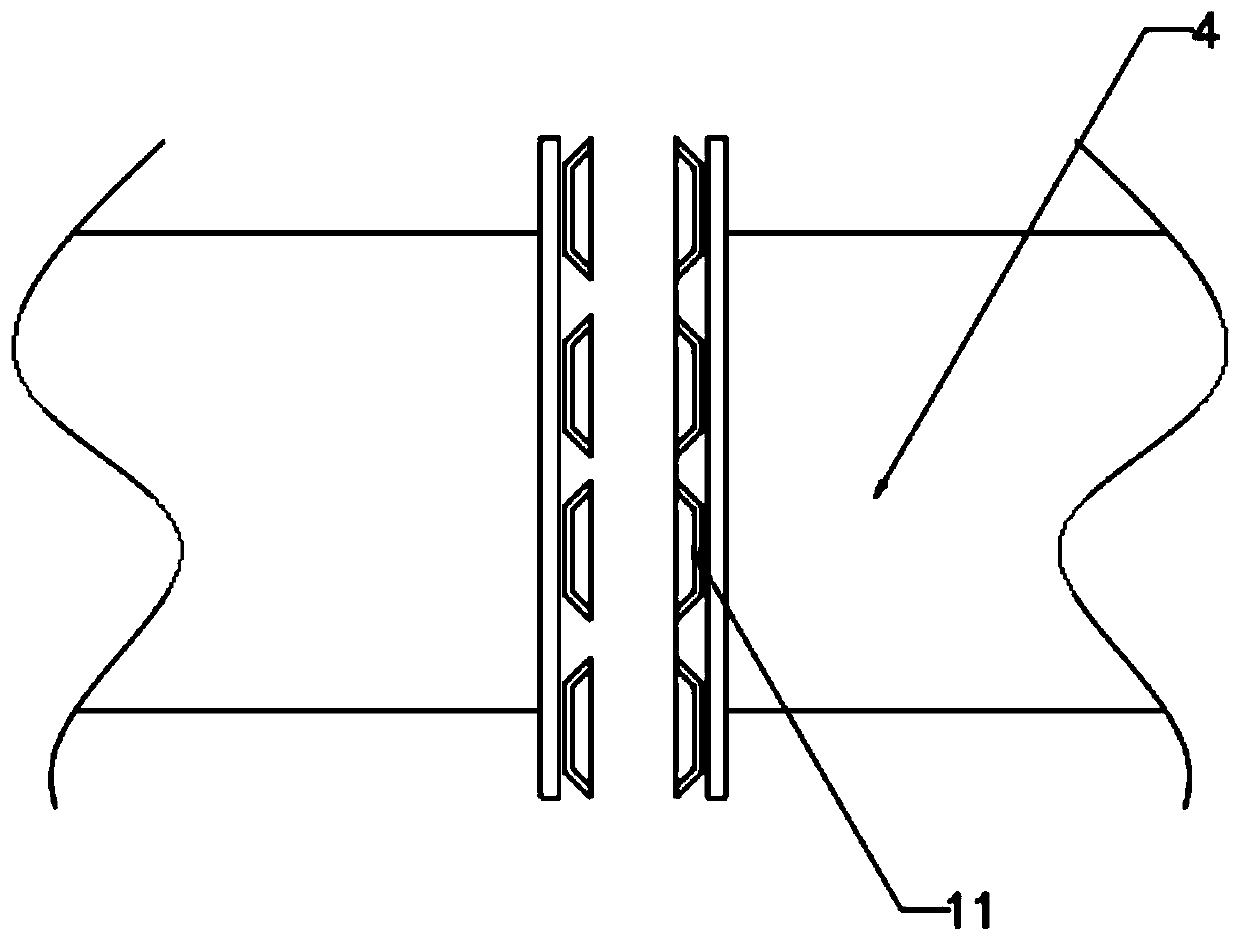

[0027] see Figure 1-3 , a bottom knife dotted line knife, including a workbench 1, and 75T020B 2 and T5020 3 that are slidingly connected to each other on the workbench 1, and a film cutting roller 4 that is rollingly connected on the workbench 1, and two of the film cutting roller 4 Both ends are welded with a limit ring 401, and the difference between the diameter of the limit ring 401 and the diameter of the dotted line knife 11 is two thicknesses of 75T020B2. The two ends of the film cutting roller 4 are provided with a driving mechanism 5, and the driving mechanism 5 drives the film cutting roller 4 through an internally provided drive motor, and the film cutting roller 4 rotates. The dotted line knife 11 cuts the upper 75T020B 2, the gap between the dotted line knives 11 will take away the waste generated after cutting, and the driving mechanism 5 passes through the two first electric telescopic rods 6 and the film cutting roller The two ends of 4 are connected by tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com