An electromechanical actuator and its control method

An electromechanical actuator and control method technology, applied in the electromechanical servo field, can solve the problems of restricting the application expansion in the aviation field, blocking or jamming, reducing the reliability of the electromechanical actuation system, etc. Stroke, the effect of reducing the key connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

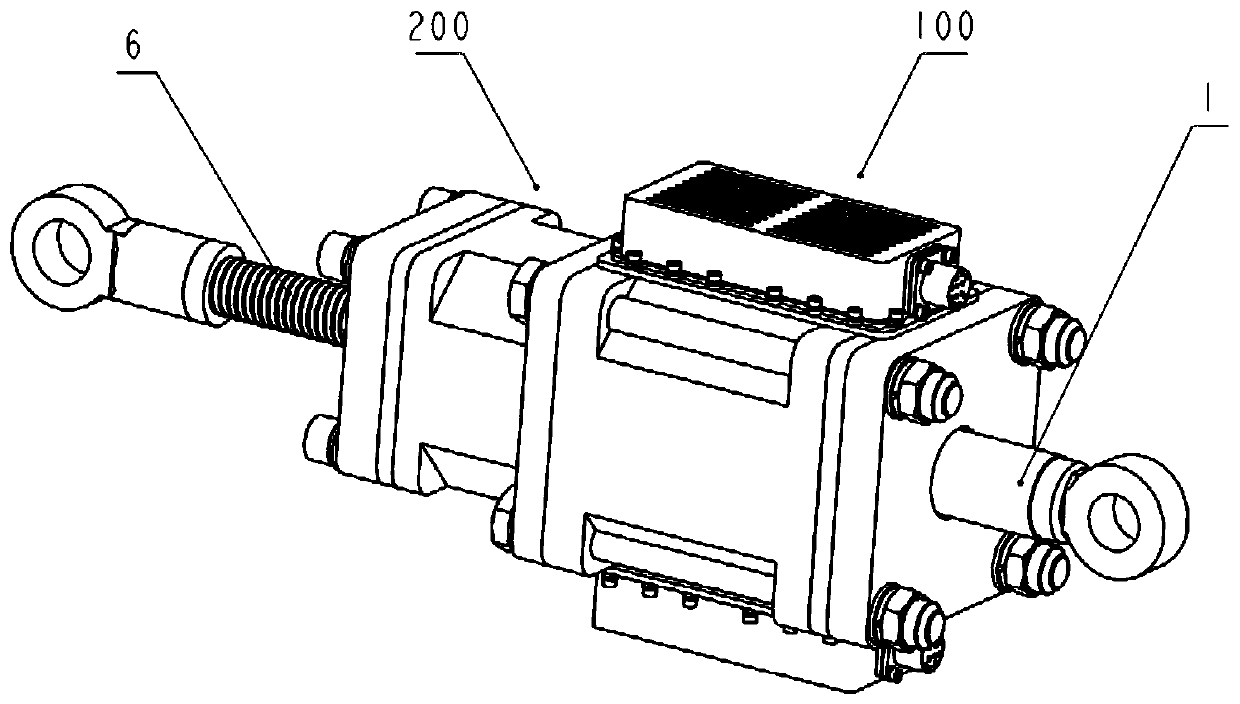

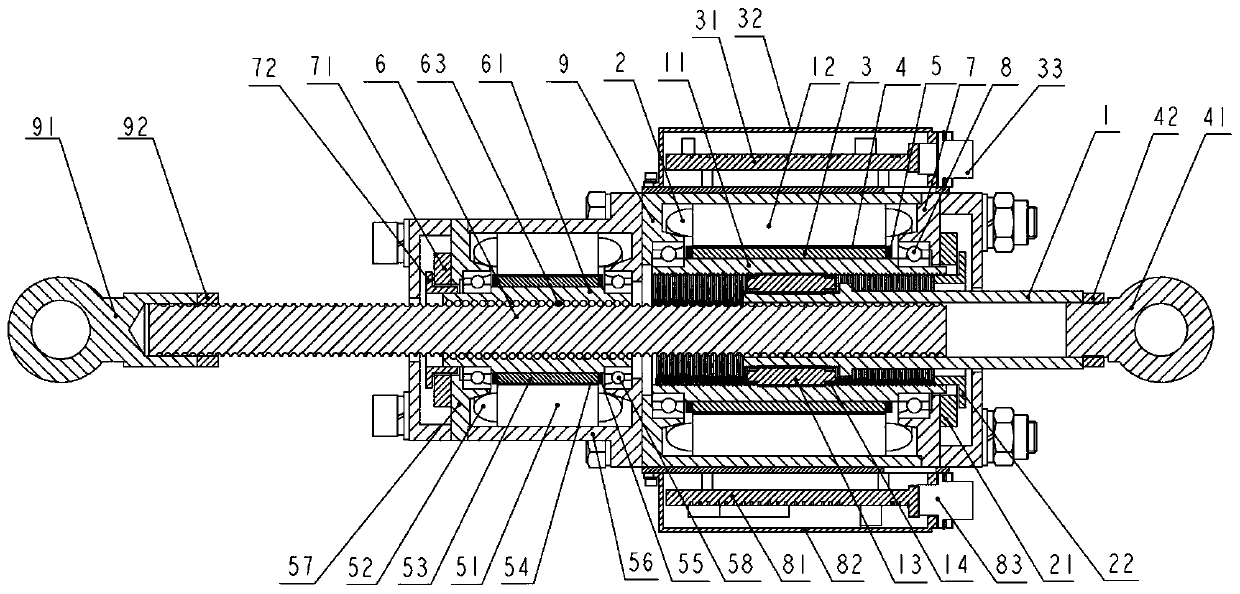

[0054] Such as figure 1 with 2 As shown, the embodiment of the present invention provides a telescope-type double redundancy electromechanical actuator, which mainly includes the following components: main position servo motor (first motor assembly 100), main position transmission mechanism, main position brake, and main position control The driver, the main connection lug, the sub-position servo motor (second motor assembly 200), the sub-position transmission mechanism, the sub-position brake, the sub-position control driver, and the sub-position connection lug.

[0055] Among them, the main servo motor includes: a first stator 12, a first winding 2, a first rotating shaft 11, a first magnet 3, a first stainless steel sleeve 4, a first balance ring 5, a first motor housing 9, The first motor front end cover 7 and the first support bearing 8. The first stator 12 and the first winding 2 are assembled by winding, the first stator 12 and the first motor housing 9 are fitted by inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com