A Mechanical Fault Diagnosis Method Based on Probability Box Model Modification

A technology of mechanical faults and diagnostic methods, which is applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve problems affecting the correct rate of pattern recognition and overlapping between models, and solve the problems of difficult and reliable space-time registration. Strong transplant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

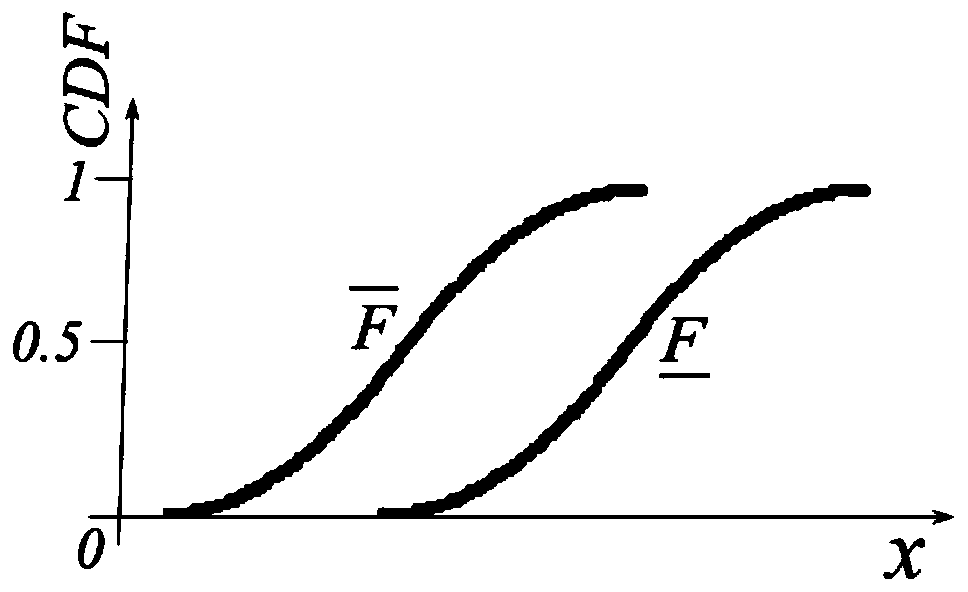

[0061] Embodiment 1: Numerical simulation: take a probability box containing 10 focal elements as an example to perform simulation calculations. Assuming that the random variable x obeys the exponential distribution, and the interval of the exponential distribution parameter λ is [2, 3], the original DSS and the improved DSS' are respectively obtained by using the probability box modeling method and the model correction method. The comparison results of simulation experiment data are shown in Table 1:

[0062] Table 1 Simulation experiment data (n=10)

[0063]

[0064]

[0065] The improved focal element interval is smaller than the original focal element interval, namely Therefore, the improvement rate of focal element compactness must also be improved. Judging from the results of focal element compactness improvement rate, the compactness of 10 focal elements has been improved to varying degrees. The original probability obtained by adding the DSS before and after co...

Embodiment 2

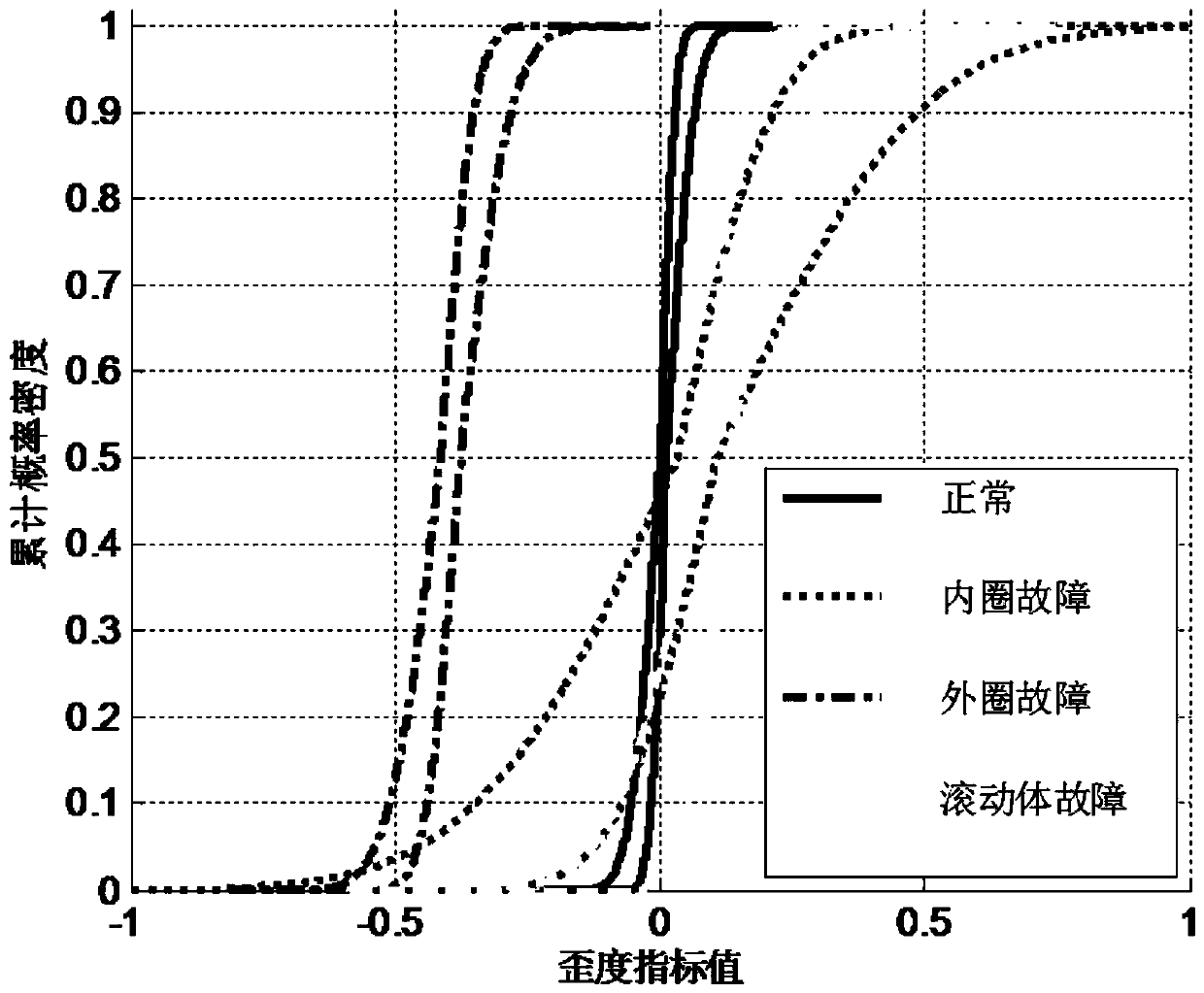

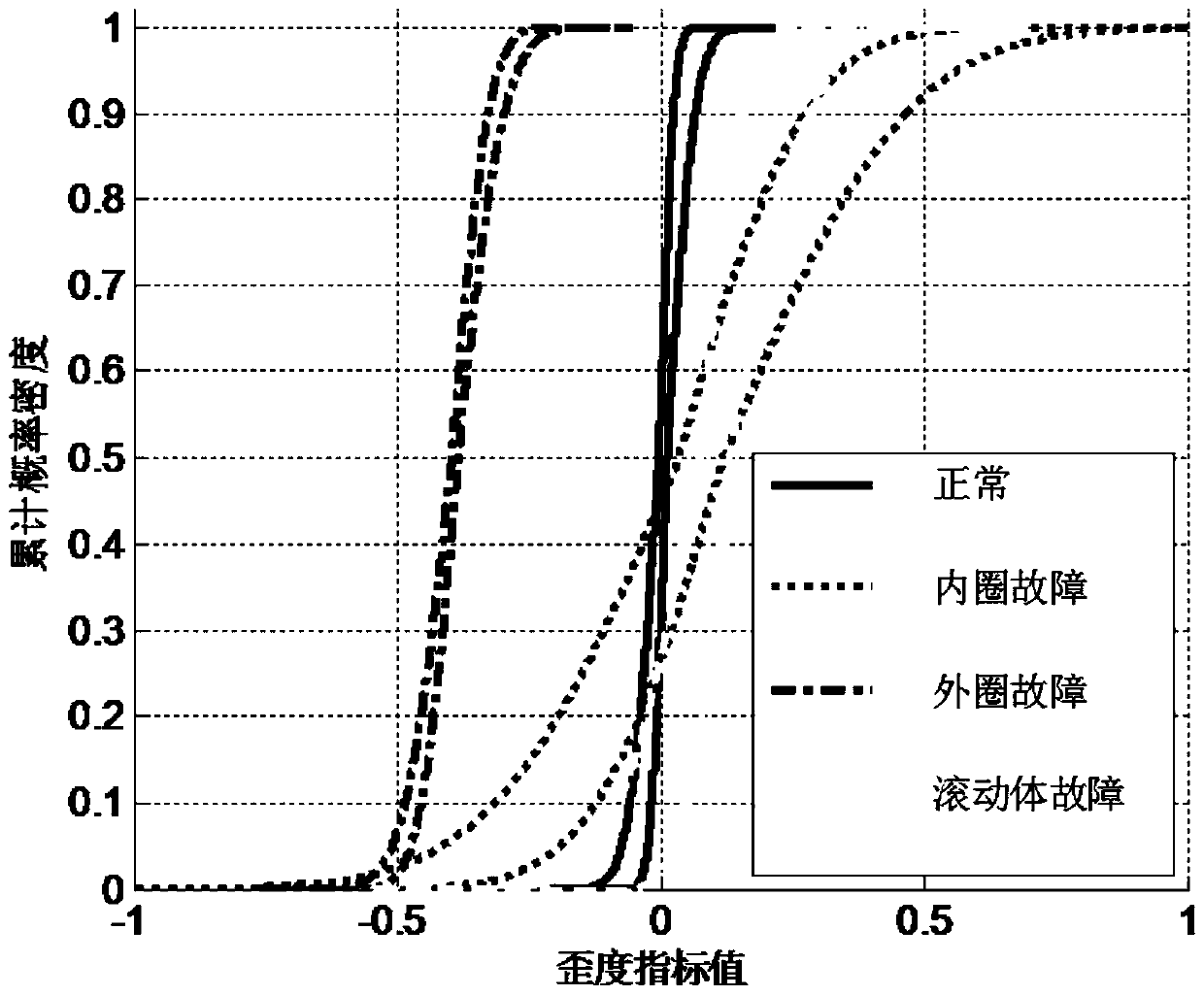

[0066] Embodiment 2: In this embodiment, the rolling fault signal is used as the experimental verification object, and the vibration acceleration signals of the normal bearing state, inner ring fault, outer ring fault and rolling element fault are respectively collected, and the original probability box model and the corrected probability are obtained The box model is as figure 1 and figure 2 shown, from figure 1 and figure 2 It can be seen that the modified probability box is more compact than the original probability box; the overlapping phenomenon of the probability box of rolling element fault and inner ring fault has been improved after the model is revised, which will be beneficial to the pattern recognition based on the probability box;

[0067] Extract the corresponding 8 feature indicators from the obtained probability boxes to form a fault feature vector group. After converting the fault signal into the corresponding skewness probability box, 100 probability boxe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com