Roadway blasting wave leakage and stone prevention device, and use method thereof

A technology of roadway and leaky waves, applied in the field of blasting flying stone protection devices, can solve the problems of the fixing problem of the protection door, which has not been solved in detail, the overall movement of the protection door is more difficult, and the assembly and lap joint process is complicated. Utilization rate, easy disassembly and transportation, and the effect of avoiding manual disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following content describes the specific implementation manner of the present invention in detail in conjunction with the accompanying drawings.

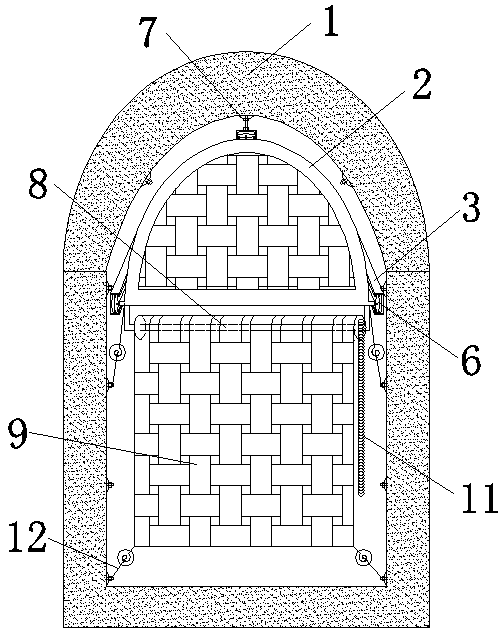

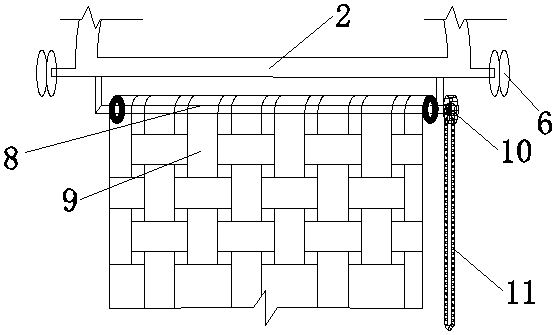

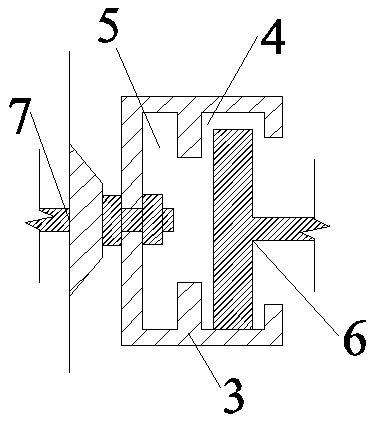

[0022] The structure of a roadway blasting leaking stone blocking device of the present invention is as follows: it is composed of a semicircular arched steel frame 2, a sliding track 3, a lifting reel 8 and a fixed cable 12, and it is characterized in that the semicircular arched steel frame 2 Inlaid with rubber woven quilt 9, a roller 6 is provided at both ends of the frame vault and the bottom, and the roller 6 can drive the semicircular arch steel frame 2 to move forward and backward through the sliding track 3 installed on the surrounding rock 1 of the roadway; the sliding track 3 is segmented, each section is 2m in length, fixed to the surrounding rock 1 of the roadway through the anchor rod 7 at the vault of the roadway and the two shoulders, the sliding track 3 and the end of the anchor rod 7 are connected by bolts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com