A single-acting pneumatic locking type flexible in-pipe robot and its working method

A technology of robots and flexible pipes, applied in the direction of pipe components, special pipes, mechanical equipment, etc., can solve the problems of load increase, complex control, and multiple power units, so as to reduce the traction load, compact and reliable structure, and realize cable-free Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

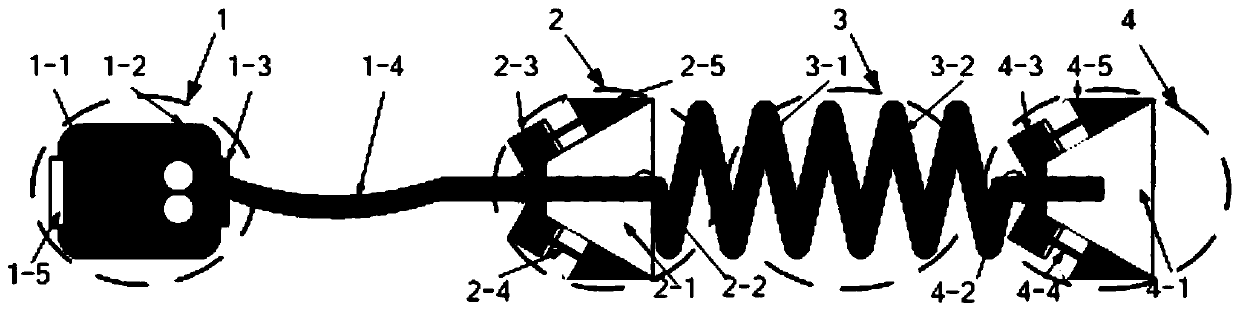

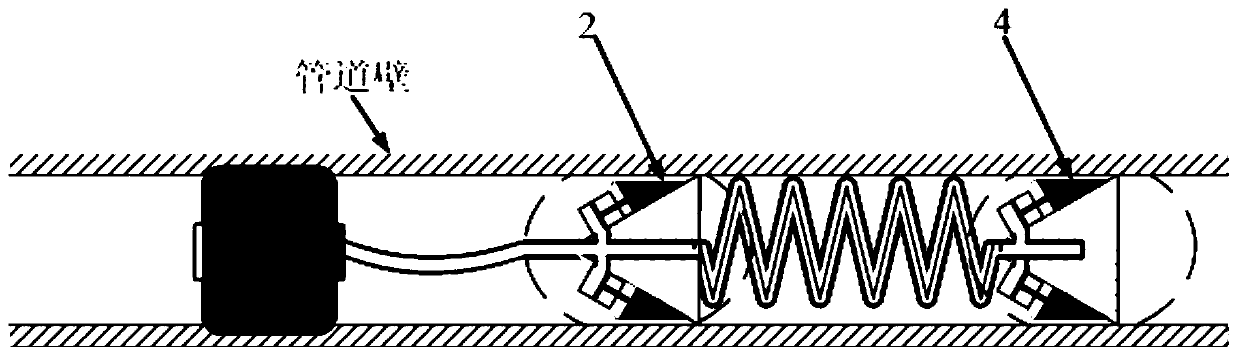

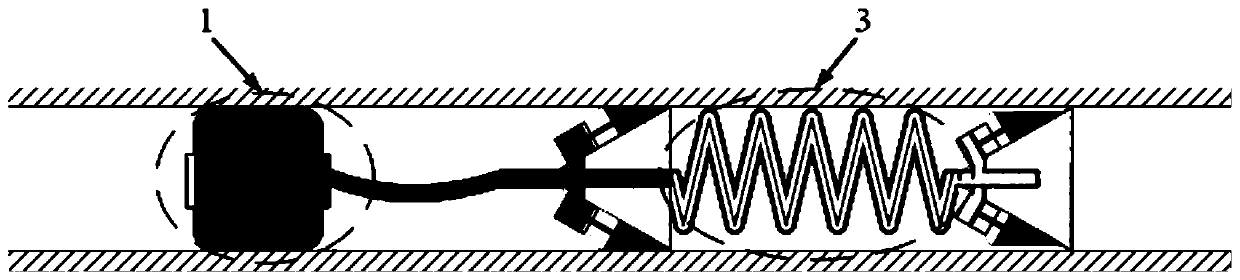

[0041] Such as figure 1 shown.

[0042] A single-acting pneumatic lock-type flexible in-pipe robot, including an energy module 1, a rear support mechanism 2 and a front support mechanism 4 connected by a telescopic mechanism 3;

[0043] The energy module 1 includes a motor 1-1, an airbag 1-2 and an air pump 1-3;

[0044] The rear support mechanism 2 includes a first truncated cone 2-1 and a first piston arranged on the circumference of the first truncated cone 2-1; the piston rod 2-4 of the first piston is connected with a first wedge 2- 5;

[0045] The telescopic mechanism 2 includes a telescopic spring 3-1 and a second air pipe 3-2 wrapped on the outside of the telescopic spring 3-1;

[0046] The front support mechanism 4 includes a second truncated cone 4-1 and a second piston arranged on the circumference of the second truncated cone 4-1; the piston rod 4-4 of the second piston is connected with a second wedge 4- 5;

[0047]The air pump 1-3 communicates with the cylin...

Embodiment 2

[0049] The difference is that the energy module further includes a wireless energy transmission module 1-5 for the single-acting pneumatic locking flexible in-pipe robot described in Embodiment 1. The wireless energy transmission modules 1-5 provide energy for the energy module 1 . The motor 1-1, the air pump 1-3 and the wireless energy transmission module 1-5 are wrapped in the airbag 1-2. In order to prevent rigid collision with the pipe wall during the movement.

Embodiment 3

[0051] Like the single-acting pneumatic locking flexible in-pipe robot described in Embodiment 1, the difference is that the rear support mechanism 2 includes three first pistons; the three first pistons are arranged at equal intervals on the first truncated cone 2 - on the circumference of 1; the front support mechanism 4 includes three second pistons; the three second pistons are arranged at equal intervals on the circumference of the second truncated cone 4-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com