Self-sucking water pipe used for fire-fighting water pump

A self-priming, water pipe technology, applied in the pipeline field, can solve problems such as high failure rate, expensive vacuum pump, and affecting the performance of fire pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

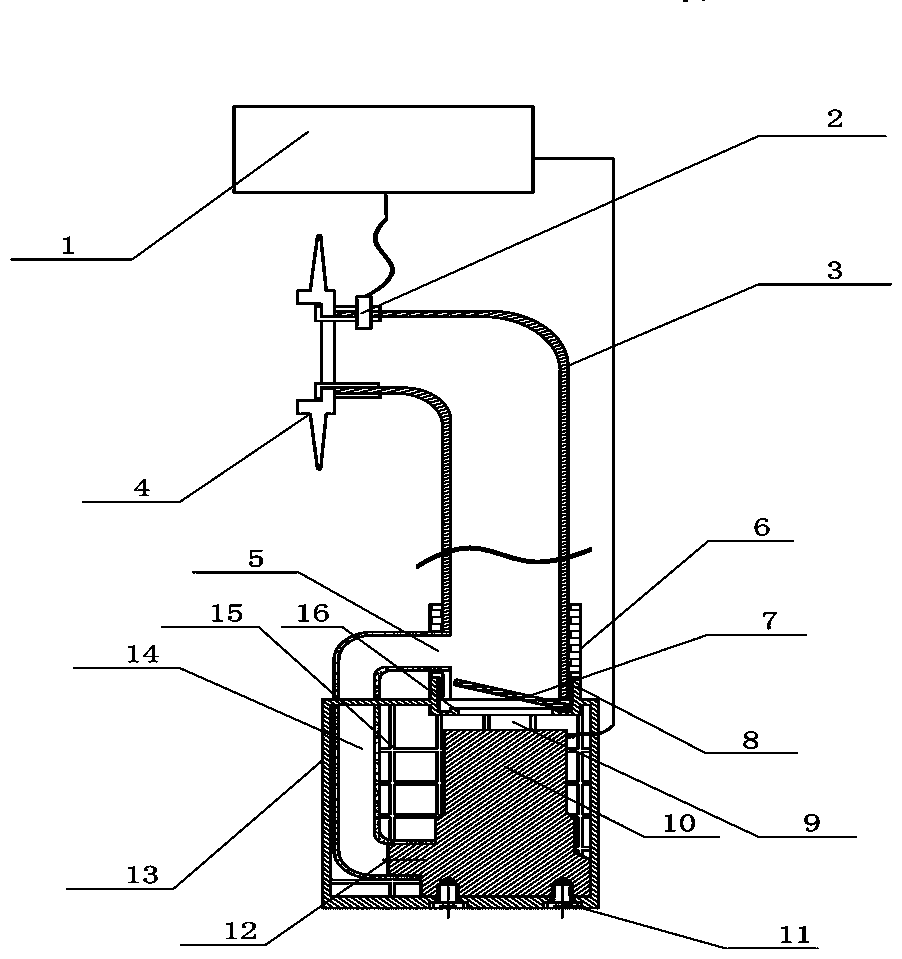

[0010] Such as figure 1 Shown is a self-priming pipe for a fire-fighting water pump, which includes a self-priming pipe 3 connected to a fire-fighting water pump at one end, and a self-priming device with a built-in submersible pump 10 connected to the other end of the self-priming pipe 3. The self-priming device includes a housing 13, and the housing 13 A vertical submersible pump 10 is installed inside, the position of the submersible pump water inlet 9 is higher than that of the submersible pump outlet 12, and the top of the submersible pump water inlet 9 is provided with an extension pipe 8 of the shell, and the extension pipe 8 is threadedly connected to one end of the joint 6, and the joint 6. The other end is connected to the self-suction pipe 3, and the extension pipe 8 is provided with a reduced-diameter port 16 between the self-suction pipe 3 and the water inlet 9 of the submersible pump. The upper side of the reduced-diameter port 16 is equipped with a rubber flap 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com