Piston pin boss for diesel engine

A piston pin seat and piston pin technology, applied in the direction of pistons, mechanical equipment, engine components, etc., can solve the problems of fast wear rate of piston pins, difficulty in lubrication, affecting the reliability and durability of diesel engines, etc., to achieve small wear and good lubrication Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will now be further described in conjunction with specific examples. The following examples are intended to illustrate the present invention but not to further limit the present invention.

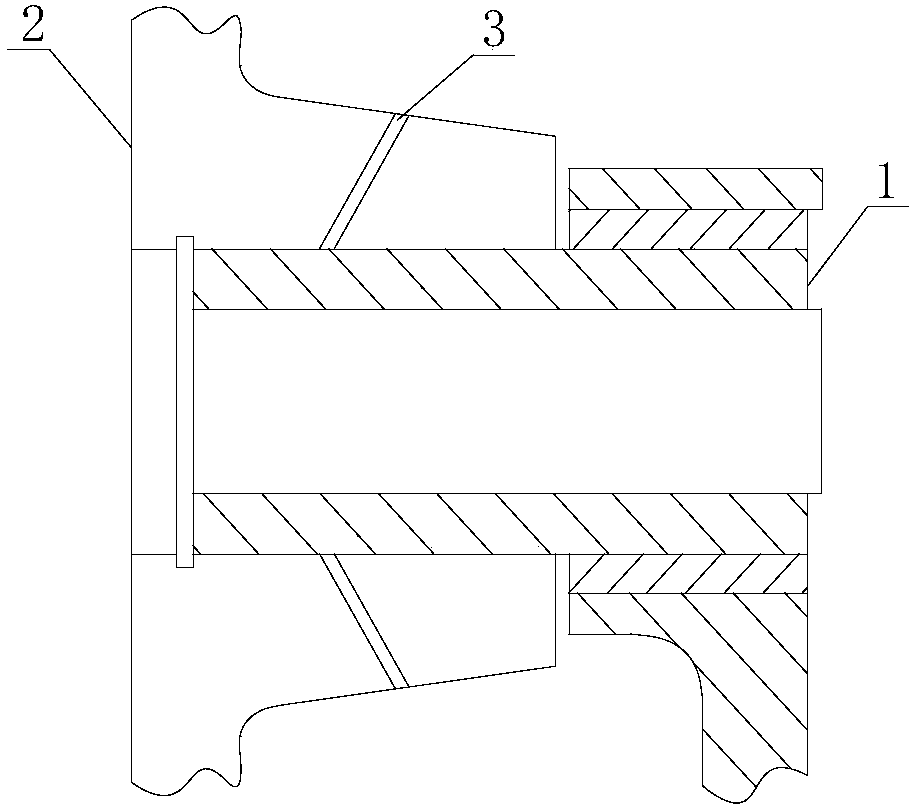

[0011] Such as figure 1 The piston pin seat for a diesel engine shown is connected to the outer side of the piston pin 1, and the piston pin seat 2 connected to the piston pin 1 is provided with an oil hole 3.

[0012] Taking the above-mentioned ideal embodiment according to the present invention as enlightenment, through the above-mentioned description content, relevant workers can make various changes and modifications without departing from the scope of the technical idea of the present invention. The technical scope of the present invention is not limited to the content of the description, and its technical scope must be determined according to the scope of the claims.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com