Unwinding and winding device and use method thereof

A technology for rewinding and unwinding rolls and rolls, which is applied in the field of automation equipment and can solve problems such as uneven upper ends of veneer rolls and unstable placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

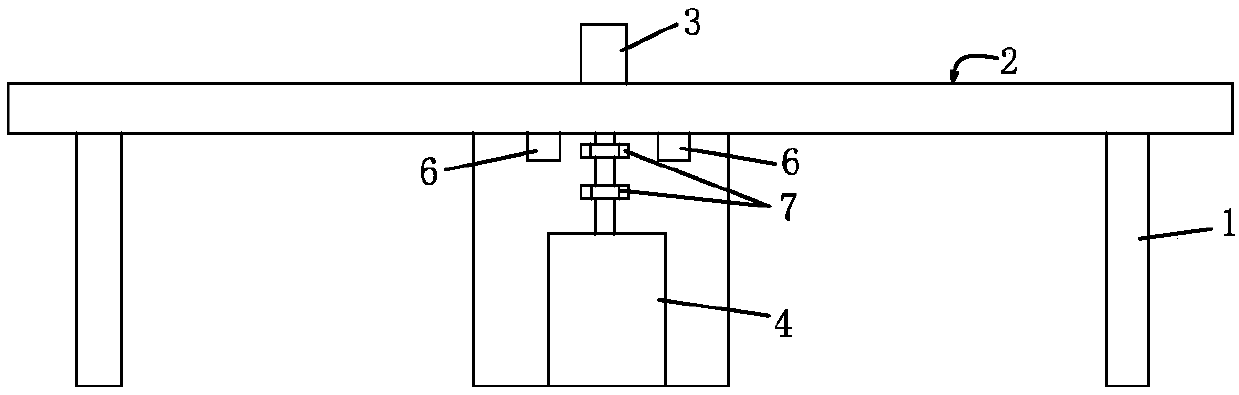

[0016] Such as figure 1 A retractable winding device shown includes a winding platform 2 installed on a bracket 1, the table surface of the winding platform 2 is a smooth plane, and an inflatable shaft 3 is installed on the winding platform, and the inflatable shaft 3 The lower end is connected by the drive shaft of the drive motor 4 through the transmission device, and the inflatable shaft 3 is driven by the drive motor 4 to rotate forward or reversely according to its functional requirements. In order to ensure that the inflatable shaft can rotate smoothly. Bearings are arranged on the drive shaft of the expansion shaft or the drive motor or the connecting shaft connecting the air expansion shaft and the drive shaft of the drive motor, and are connected to the support 1 by the bearing seat 7 . The unwinding device also includes an air-expanding head used in conjunction with the air-expanding shaft 3, and a shelf for placing the air-expanding head is provided on the support 1...

Embodiment 2

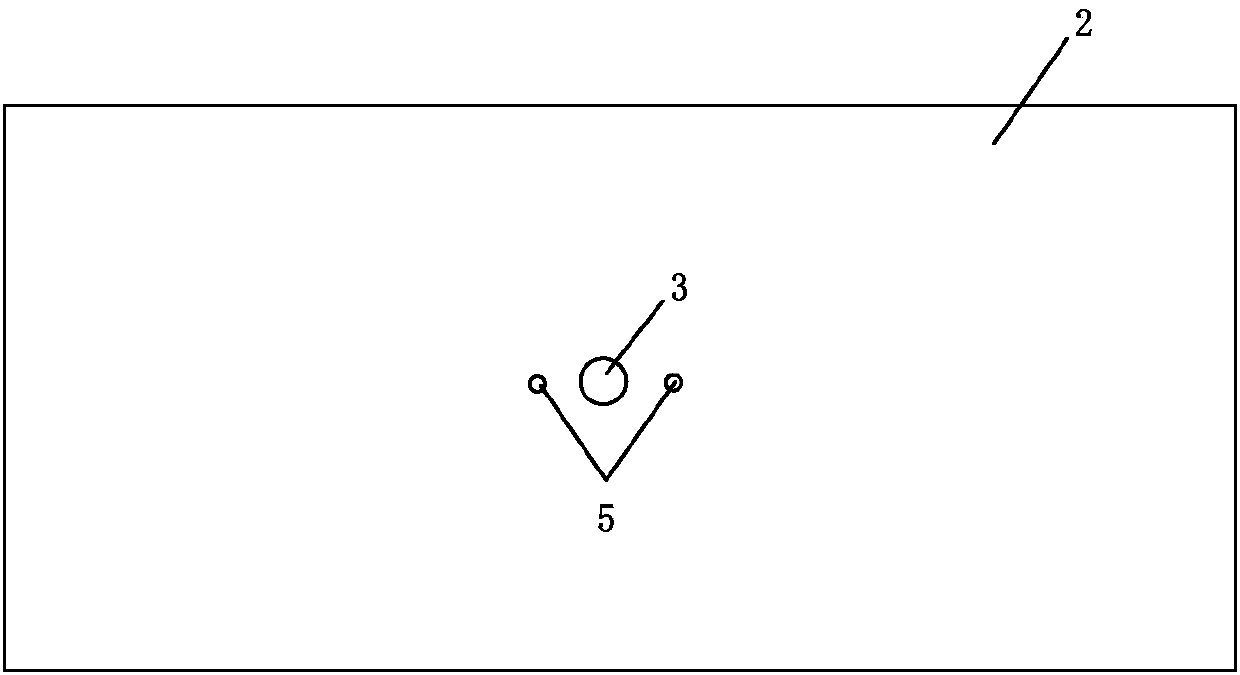

[0023] The difference between this embodiment and Embodiment 1 is that the winding platform is provided with at least two jacking blocks 5 arranged symmetrically along the inflation axis, and the jacking blocks 5 are arranged in the winding area of the veneer roll to lift The block 5 can be lifted and installed on the winding platform 2, and the lower end of the jack-up block 5 is connected with the telescopic rod of the driving cylinder 6. When the telescopic rod of the driving cylinder 6 is in the retracted state, the upper end surface of the jacking block 5 is lower than or flush with the table surface of the winding platform 2 . After the telescoping rod of driving cylinder 6 stretches out, the jacking block is jacked up, so that the upper end of the jacking block 5 stretches out a distance above the table top of the winding platform.

[0024] After the veneer roll is completed through the inflatable shaft 3 and the pressure plate, it may be difficult to take out the ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com