Working method of intelligent garbage can for manipulator rotary garbage throwing

A technology for throwing garbage and working methods, applied in trash cans, garbage collection, household appliances, etc., can solve the problems of bad working environment, high work intensity, human body damage, etc., to improve environmental protection awareness, reduce workload, reduce The effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

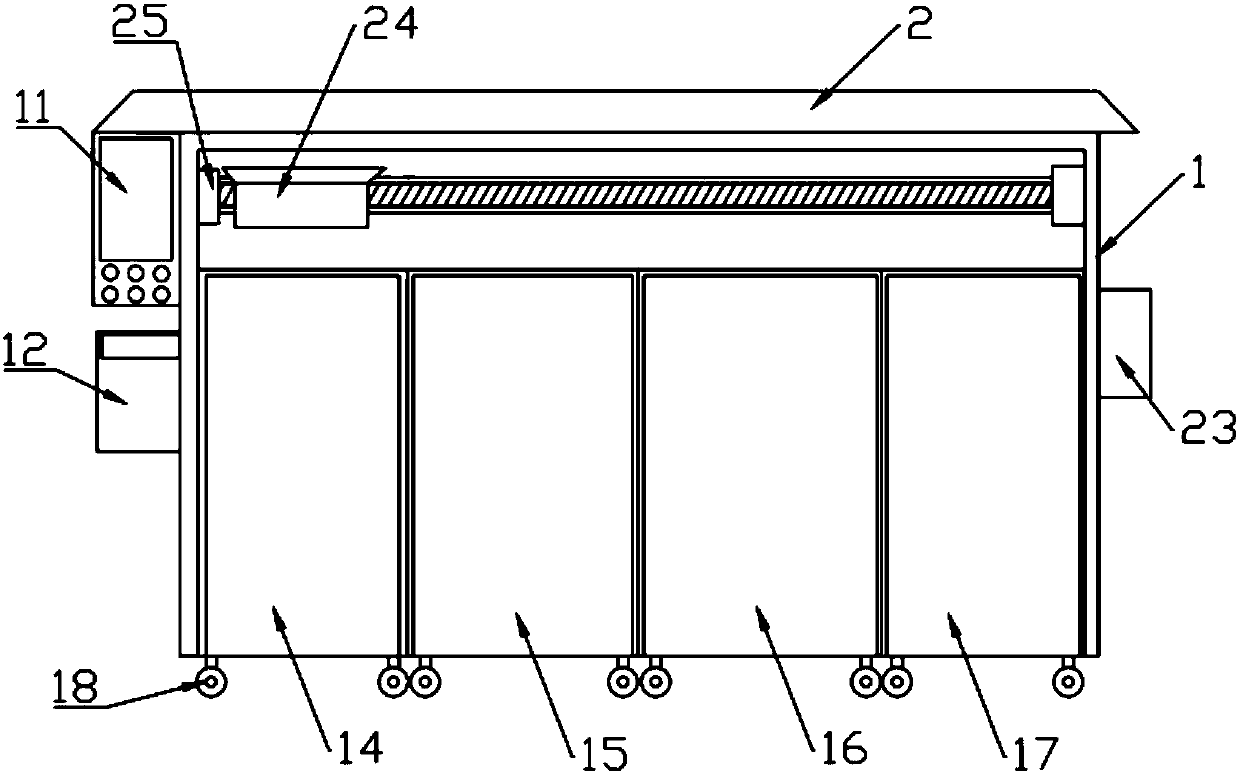

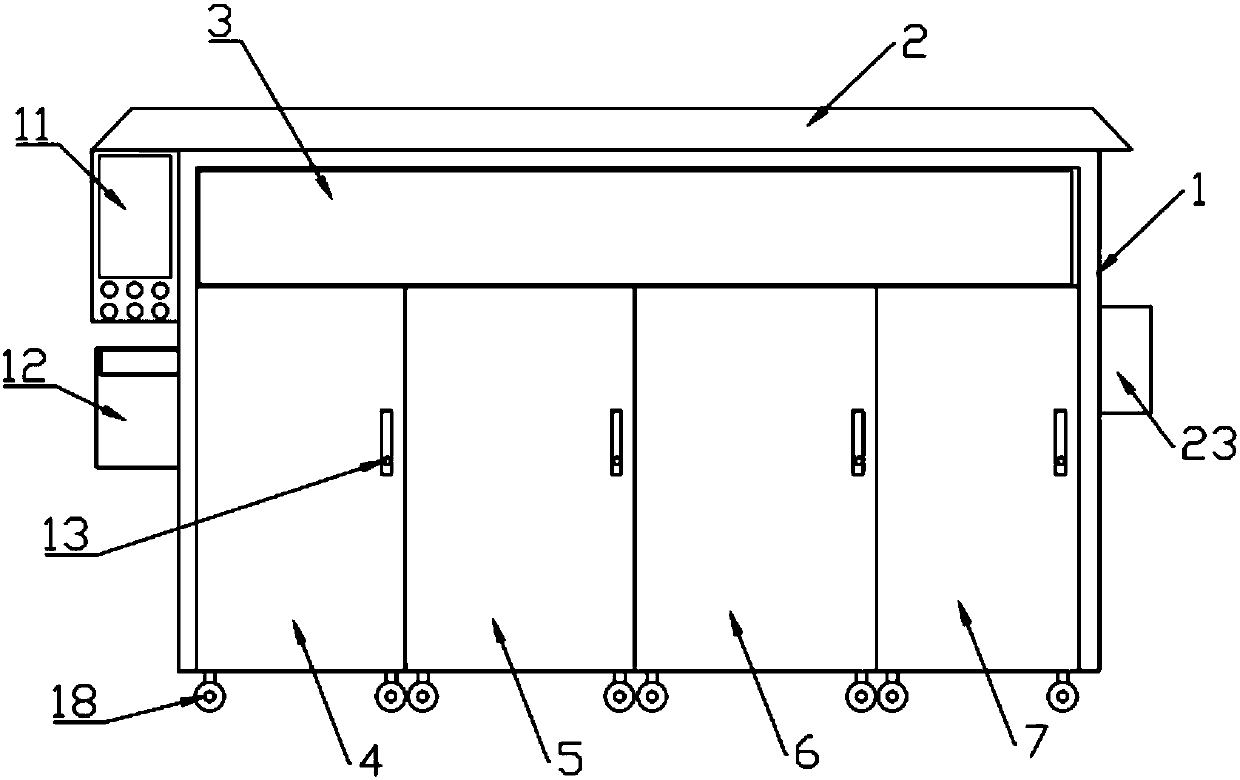

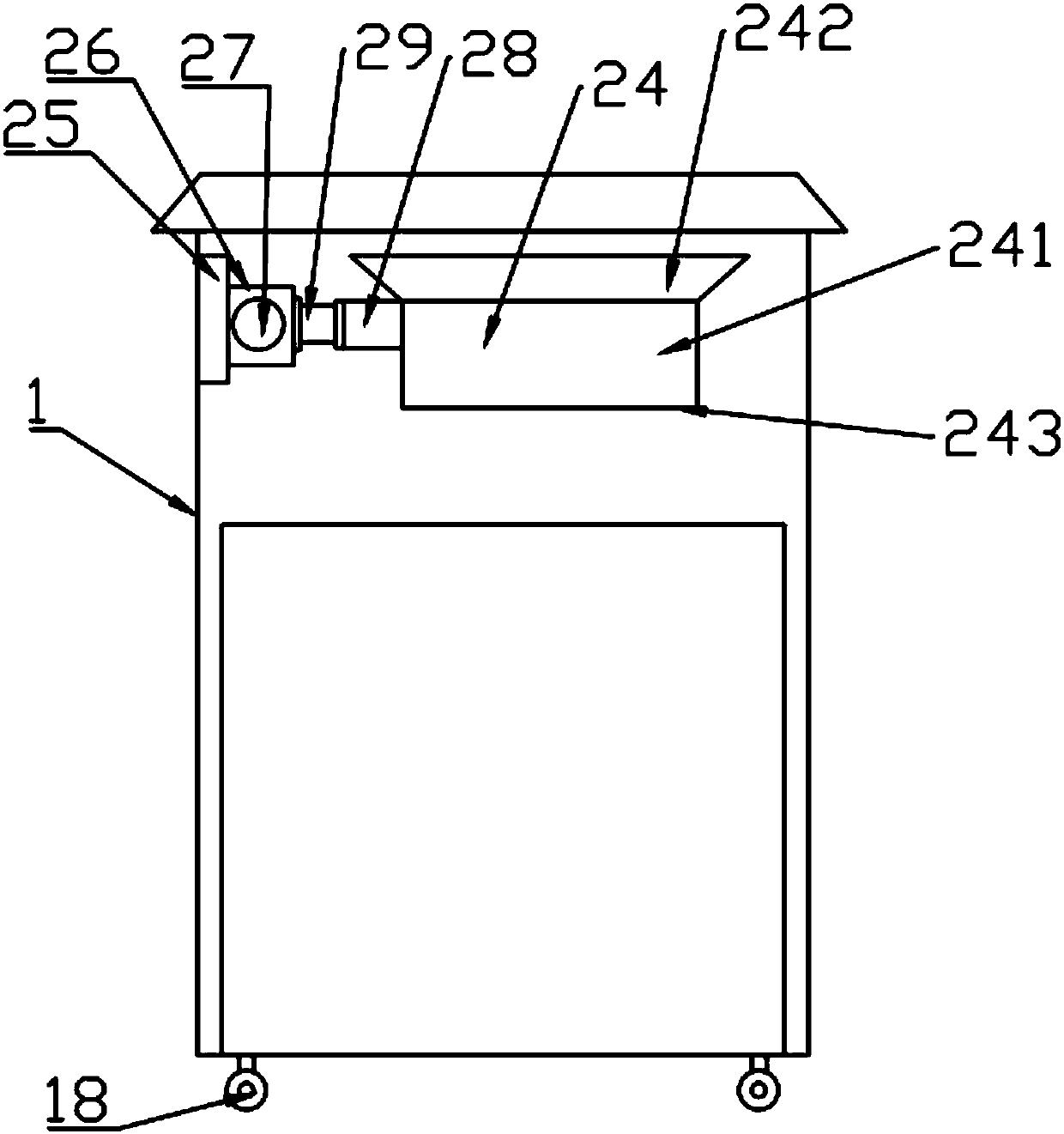

[0036] like Figure 1-3 The shown intelligent trash can for manipulator rotation type garbage disposal includes a trash can body 1, an upper top cover 2, a box door 3, a first trash can door 4, a second trash can door 5, a third trash can door 6, The fourth trash can door 7, the man-machine console 11, the first trash can 14, the second trash can 15, the third trash can 16 and the fourth trash can 17, the upper cover 2 is located on the trash can box 1 The upper end of the top cover 2 is trapezoidal, and the door 3 is connected with the trash can body 1, the first trash can door 4, the second trash can door 5, the third trash can door 6 and The fourth garbage can door 7 is located on the garbage can box 1, the man-machine console 11 is fixed on the side wall of the garbage can box 1, the first garbage can 17, the second garbage can 16, the third garbage can Garbage can 15 and the 4th garbage can 14 are located at the inside of garbage can casing 1; Wherein, as Figure 4 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com